Automatic poultry feeder

An automatic feeding and poultry technology, applied in the field of poultry farming, can solve the problems of feeding manpower consumption, etc., and achieve the effect of saving manpower, effective feeding, and good feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

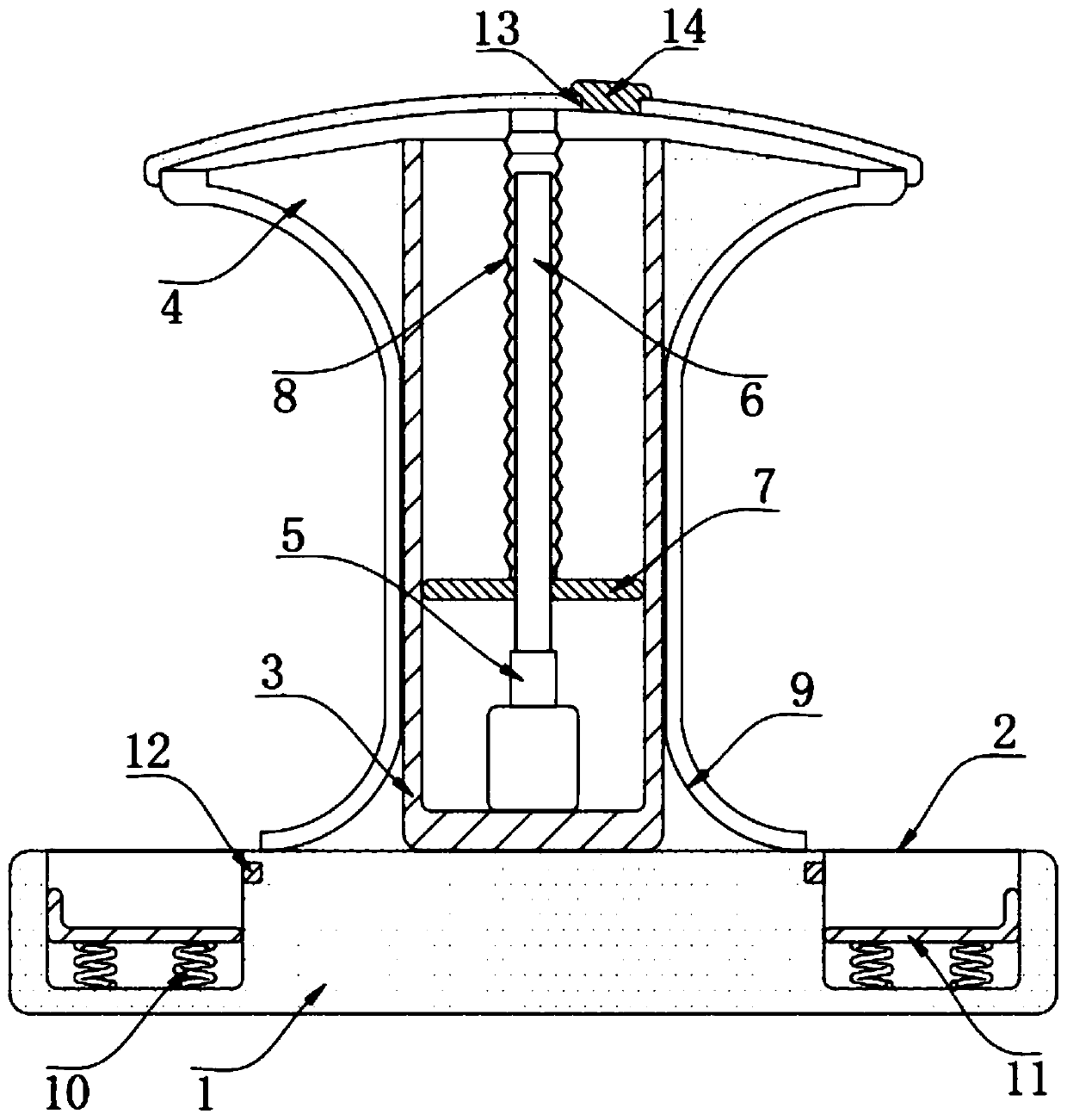

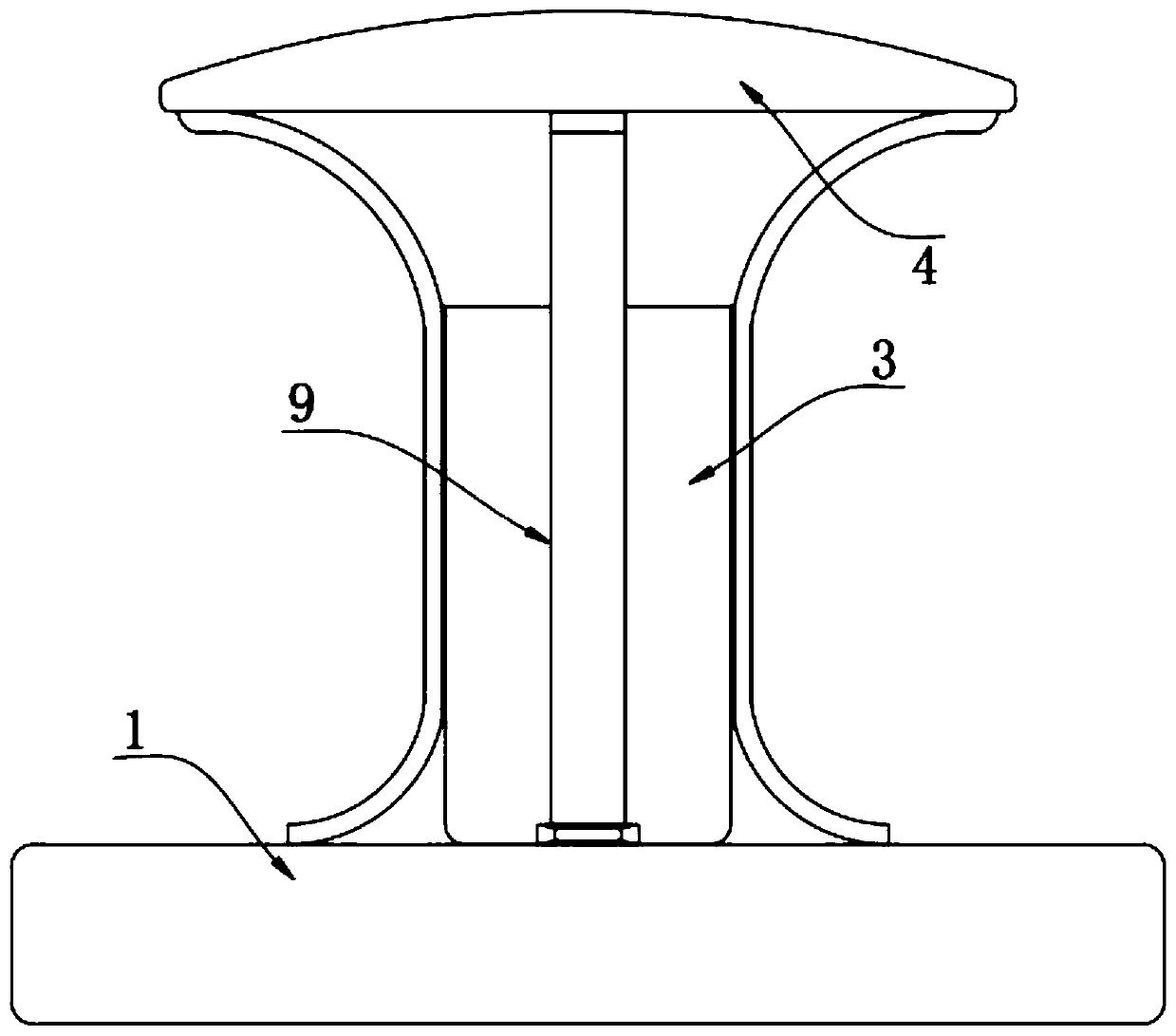

[0019] refer to Figure 1-2 , a poultry automatic feeder, comprising a base 1, the upper end of the base 1 is provided with an annular trough 2, the upper end of the base 1 is fixed with a storage box 3, the side wall of the storage box 3 is fixed with a top cover 4, the top cover The bottom of 4 is a slope, and the feed that enters from the upper end of the storage box 3 will roll along the bottom slope of the loam cake 4. The inner bottom of the storage box 3 is fixed with a motor 5, and the output shaft of the motor 5 is fixed with a screw rod 6. The circumferential side wall of the rod 6 is threadedly connected with a square push plate 7, and the screw mandrel has 6 reciprocating screw rods, which can automatically return after the push plate 7 has moved to the maximum position, which is convenient for repeated feeding. The inner top of the cover 4 is jointly fixed with a shrink film 8, the shrink film 8 is made of an elastic material, which can expand and contract and pre...

Embodiment 2

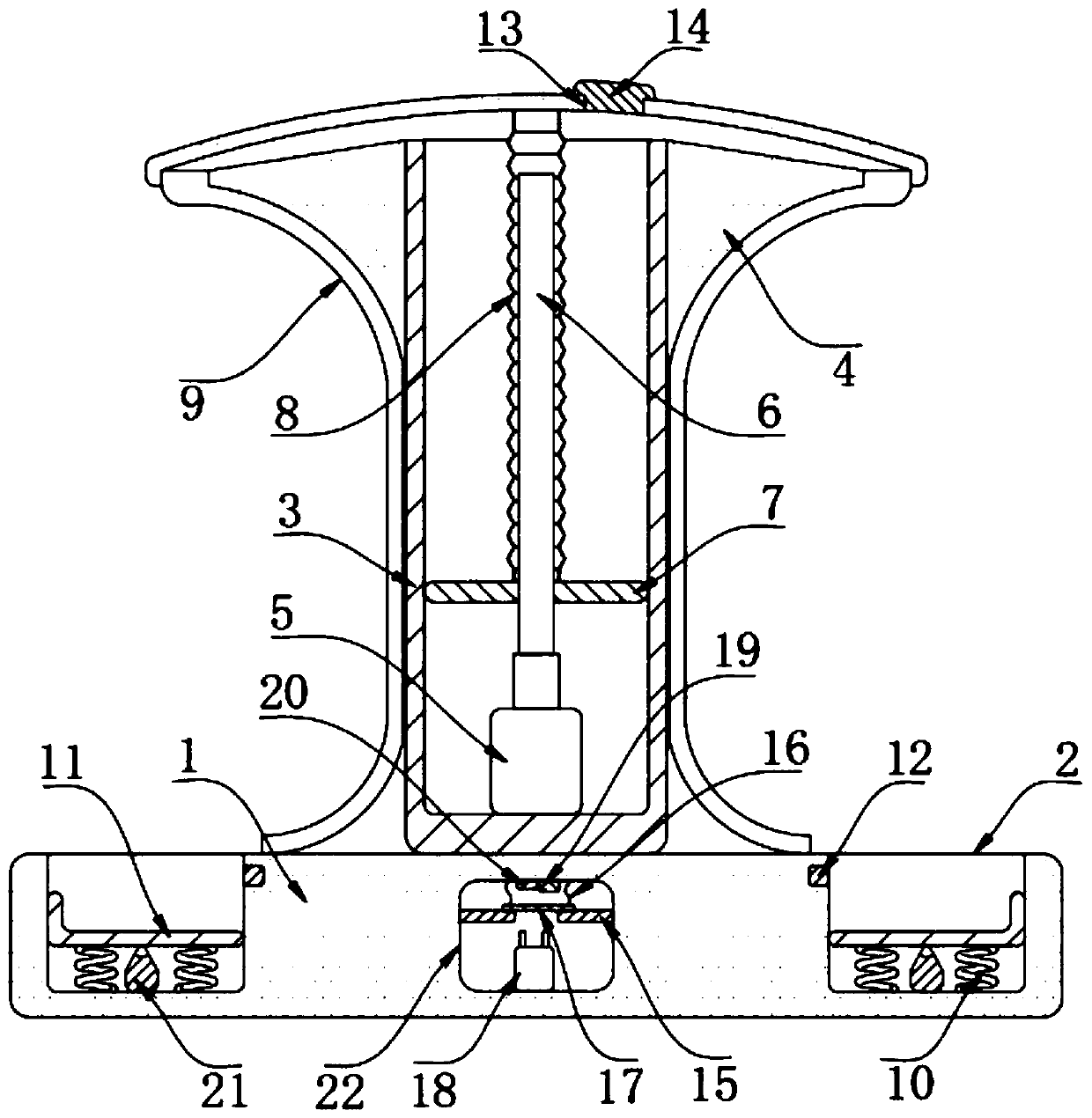

[0024] refer to Figure 1-3 The difference between this embodiment and Embodiment 1 is that a control cavity 22 is provided inside the base 1, two symmetrically arranged power plates 15 are fixed on the inner wall of the control cavity 22, and an inductor 18 is fixed on the bottom of the control cavity 22. The upper end of cavity 22 is fixed with electromagnet 19, delay magnet 20 and connecting spring 16, and delay magnet 20 is electromagnet, and the lower end of connecting spring 16 is fixed with connecting plate 17, and connecting plate 17 is permanent magnet, and connecting plate 17, two An electric connection plate 15, a photoresistor 12 and a motor 5 form a closed loop with an external power supply. The bottom of the food tank 2 is fixed with an electric shock block 21, and the bottom of the carrier plate 11 is fixed with a conductive sheet, and the electric shock block 21, conductive sheet, and inductor 18 And the delay magnet 20 forms a closed electric circuit with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com