Tray

A pallet and plate body technology, applied in the field of article supporting devices, can solve the problems of easily damaged ground, uneven surface of the pallet, affecting the stability of the goods placed on the pallet, etc. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

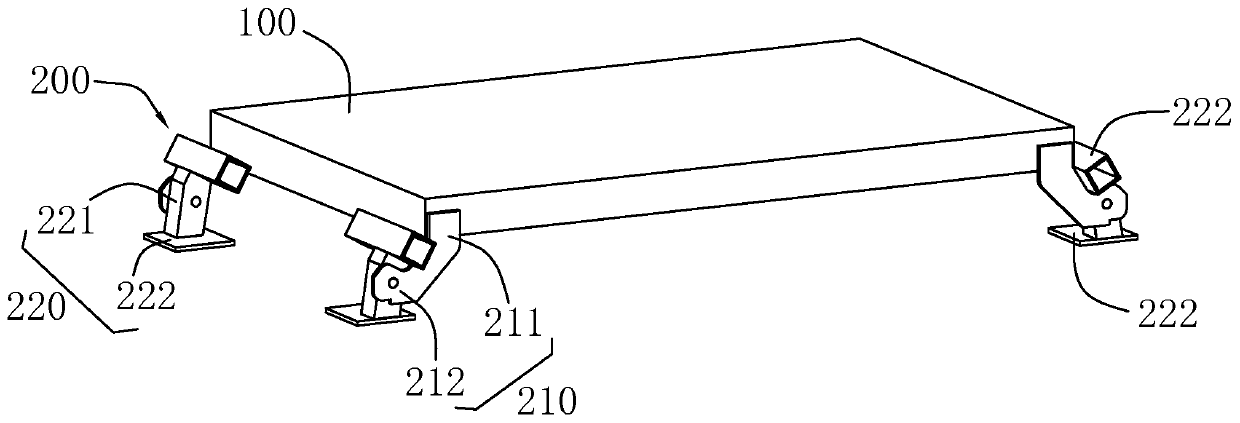

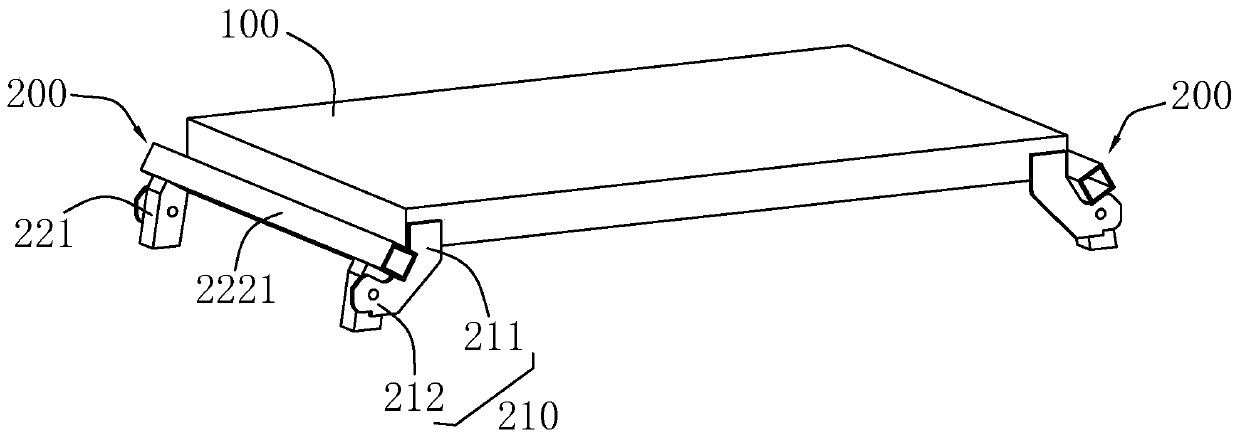

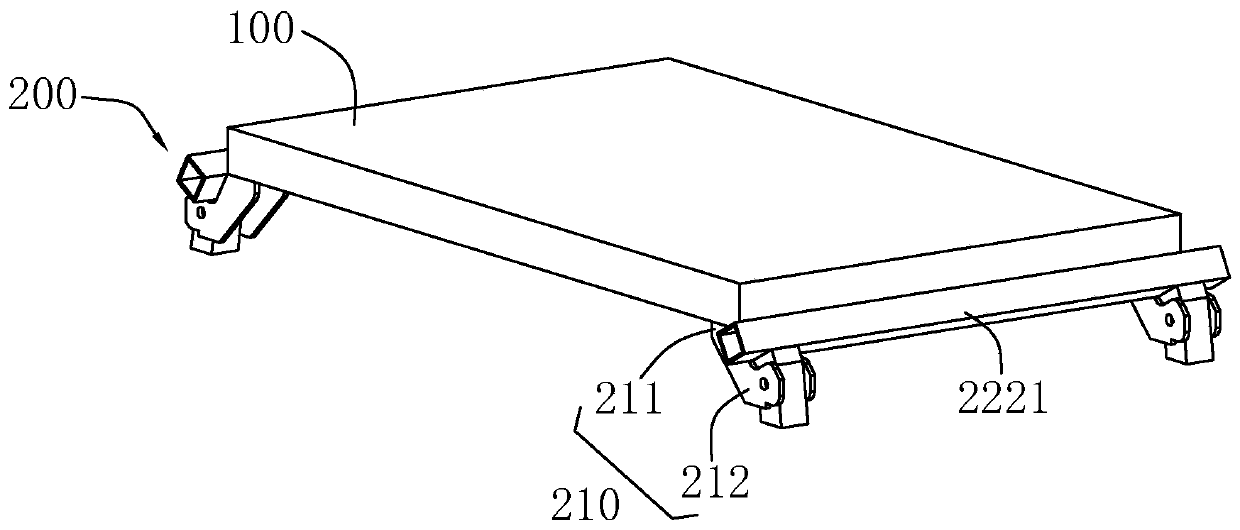

[0054] a tray such as figure 1 As shown, the tray body 100 is included, and the tray body 100 is provided with a tray support structure 200 for changing the bearing area between the tray body 100 and the external receiving surface.

[0055] like figure 1 As shown, the pallet supporting structure 200 includes a connecting portion 210 and a supporting portion 220 .

[0056] The connecting part 210 is configured to be fixedly connected to the tray body 100 , and the supporting part 220 is configured to be movably connected to the connecting part 210 for providing at least two supporting surfaces with different contact areas with the external receiving surface.

[0057] A state switching mechanism is provided between the connecting portion 210 and the supporting portion 220 to change the contact area between the supporting portion 220 and the external receiving surface.

[0058] detailed, such as figure 1 and figure 2 As shown, the tray body 100 is preferably arranged in a rect...

Embodiment 2

[0068] a tray such as Figure 5 and Image 6 As shown, the difference from Embodiment 1 is that the connection part 210 includes legs 213 arranged at the four corners of the tray body 100, the legs 213 are arranged perpendicular to the tray body 100, and the bottom of the legs 213 is provided with a soft Cushion. The supporting part 220 includes a cross bar 223 arranged between two adjacent legs 213 or between the legs 213 on the same side of the tray body 100 . Hinged with the leg 213 , the rotation plane of the connecting rod 224 is parallel to the height direction of the tray body 100 . In order to ensure that the rotation of the cross bar 223 will not be interfered by the legs 213, the length of the connecting rod 224 is not less than the length of the legs 213, that is, after the connecting rod 224 rotates, the maximum distance between the surface of the cross bar 223 and the tray body 100 is greater than The distance between the ends of the legs 213 and the tray body ...

Embodiment 3

[0076] a tray such as Figure 7 and Figure 8 As shown, the difference from the second embodiment is that: the outrigger 213 is provided with a storage groove 2135 along its length direction, the connecting rod 224 is stored in the accommodating groove 2135, and the above-mentioned connecting rod 224 and the outrigger 213 are connected by a lock. Pin 2241 realizes locking and disengagement.

[0077] Preferably, the legs 213 are arranged in an arc shape on one side facing the tray body 100, so as to facilitate stacking between two adjacent trays.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com