Locking and unlocking mechanism

An unlocking mechanism and locking technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of large space occupation, difficult disassembly, poor cleaning effect of cleaning agents, etc., and achieve convenient separation, convenient use and cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

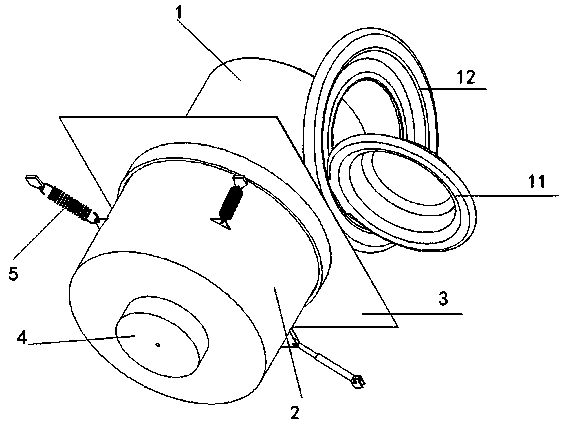

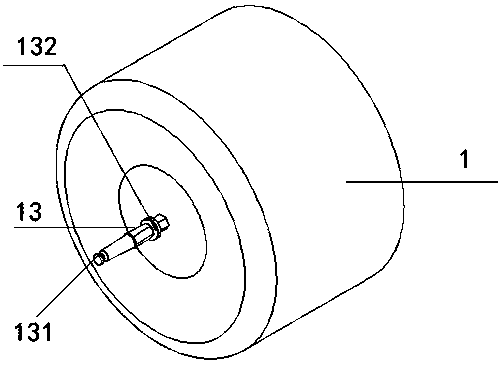

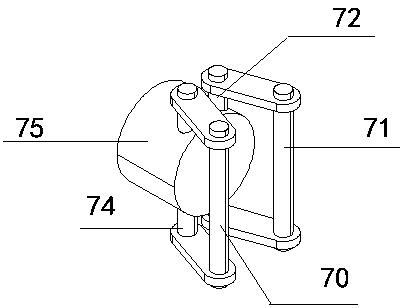

[0045] Combine below Figure 1 to Figure 17 , the present invention is further described:

[0046] Such as Figure 1-8 As shown, a washable drum washing machine includes a washing machine casing, an outer cylinder 2 is arranged in the washing machine casing, an inner cylinder 1 for washing clothes is arranged in the outer cylinder 2, and the inner cylinder 1 is driven by the inner cylinder driving motor 4 For washing or drying, the inner cylinder 1 can enter and exit the outer cylinder 2 in a linear motion and expose the space between the outer wall of the inner cylinder 1 and the inner wall of the outer cylinder 2 to facilitate the removal of dirt and harmful bacteria, and the transmission part 13 is fixed in the inner cylinder 1, the drive motor 4 is arranged at the bottom of the outer cylinder 2; when the transmission member 13 is located in the motor shaft hole 41 of the drive motor 4, the inner cylinder 1 can be rotated for washing or drying; the transmission member 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com