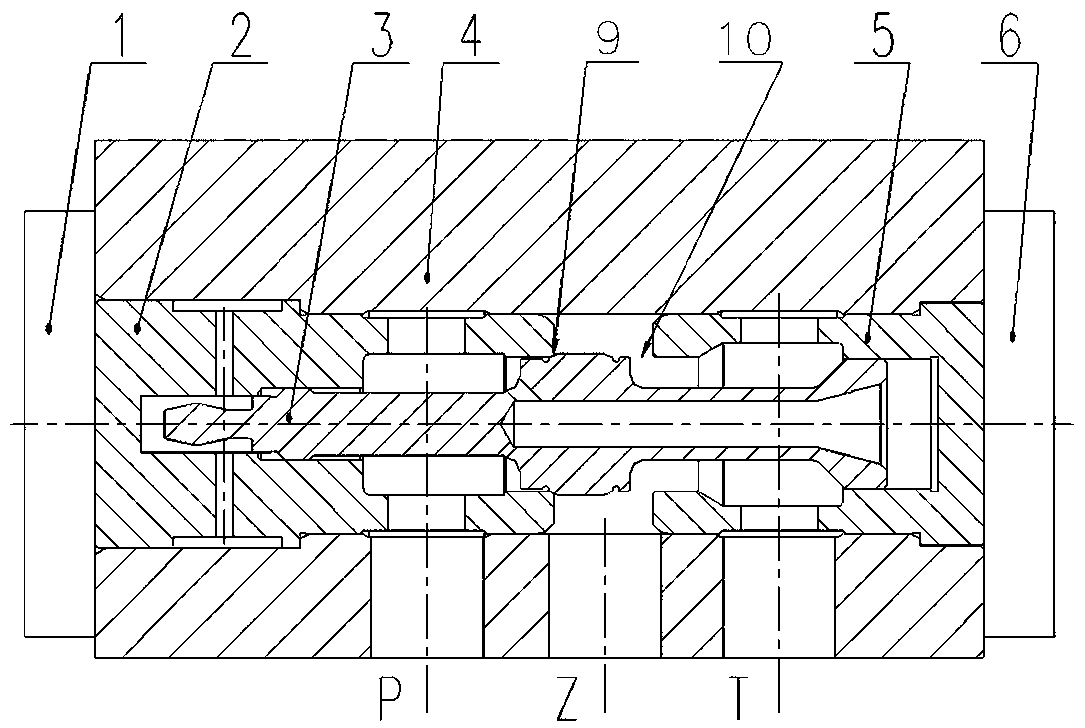

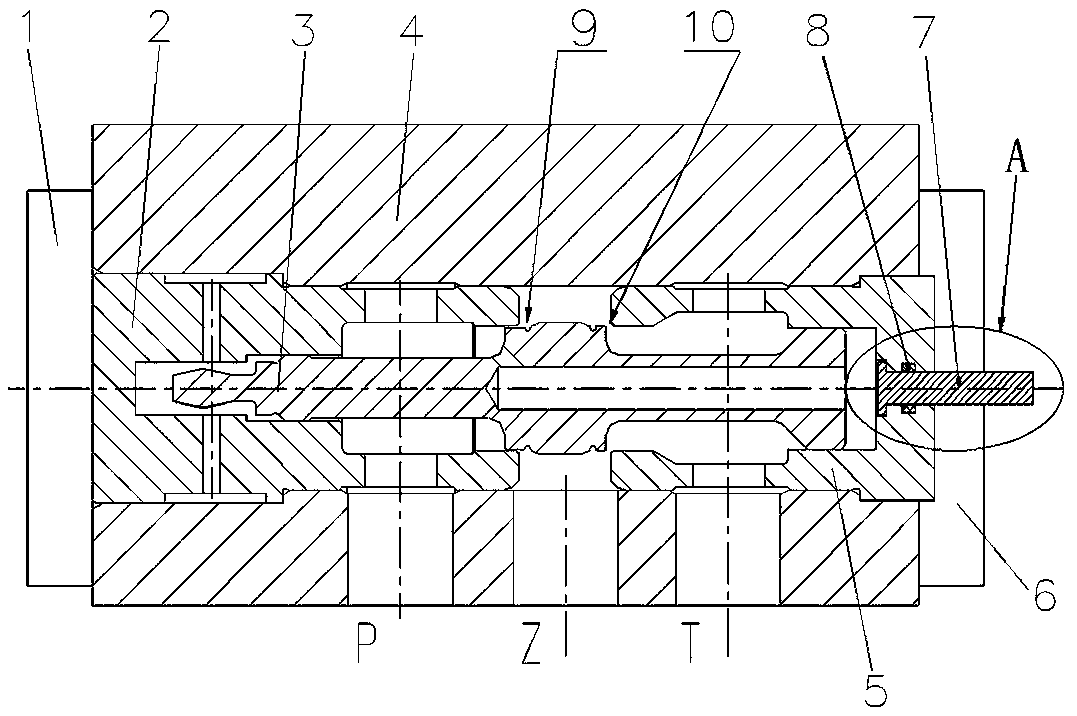

Hydraulic operating mechanism, control valve and primary valve of control valve

A technology for hydraulically operating and controlling valves, which is applied to engine components, fluid pressure actuating devices, valve details, etc. It can solve problems such as manual operation of the spool and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

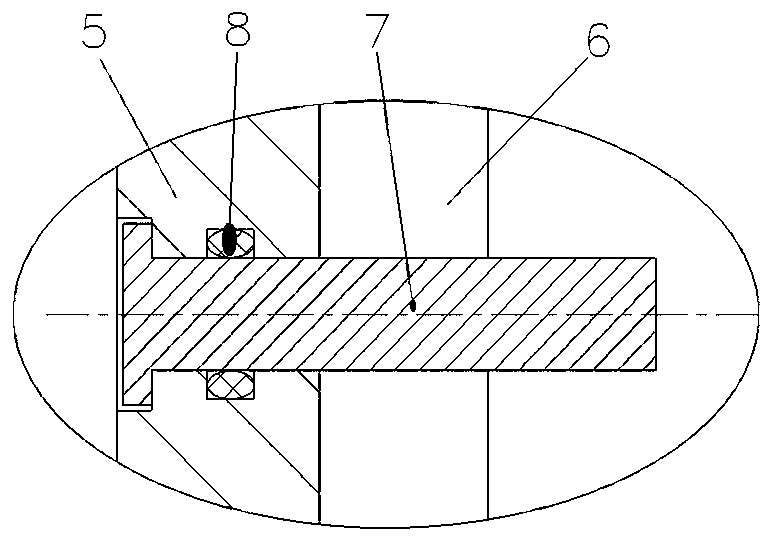

[0036] Embodiment 2, the difference between embodiment 2 and embodiment 1 is: the main valve of the control valve does not include an operating rod, and the operating rod is provided separately; when the control valve works, a blocking member, such as a screw plug, is used to seal the main valve body Plug the operating rod perforation on the top; when maintenance is required, first remove the blocking member, and then operate when the operating rod is passed into the operating rod perforation.

Embodiment 3

[0037] Embodiment 3, the difference between embodiment 3 and embodiment 1 is: one end of the operating part is screwed to the main valve spool through a threaded structure; when the main valve spool does not move in place, it is driven by pushing or pulling the operating rod The main valve spool moves.

Embodiment 4

[0038] Embodiment 4, the difference between embodiment 4 and embodiment 1 is that a spring for applying a reset force to the operating rod is provided between the operating rod and the main valve body. After the manual operation is completed, the operating rod will Automatic reset.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com