Electric ground anchor hammering installation device

A technology for installing devices and ground anchors, applied in the directions of striking tools, light impact tools, manufacturing tools, etc., can solve the problems of weak wind resistance of distribution network poles, threats to economic development, and low work efficiency, saving manpower , easy to use, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

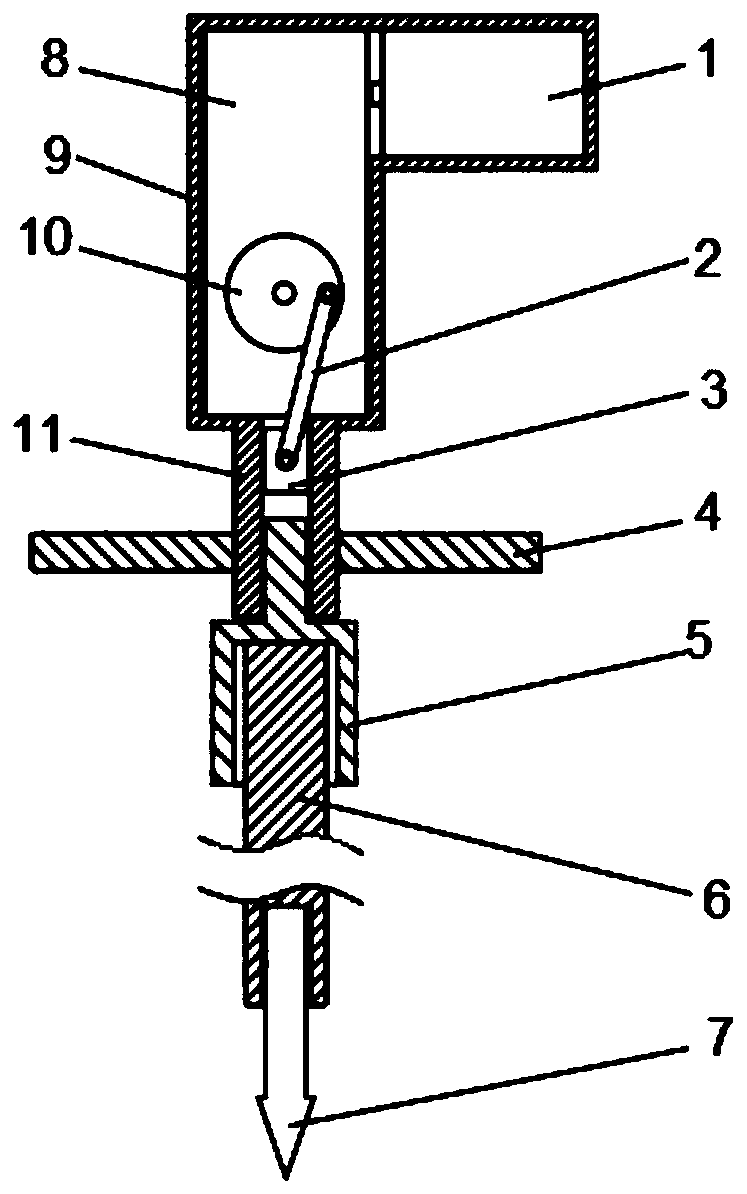

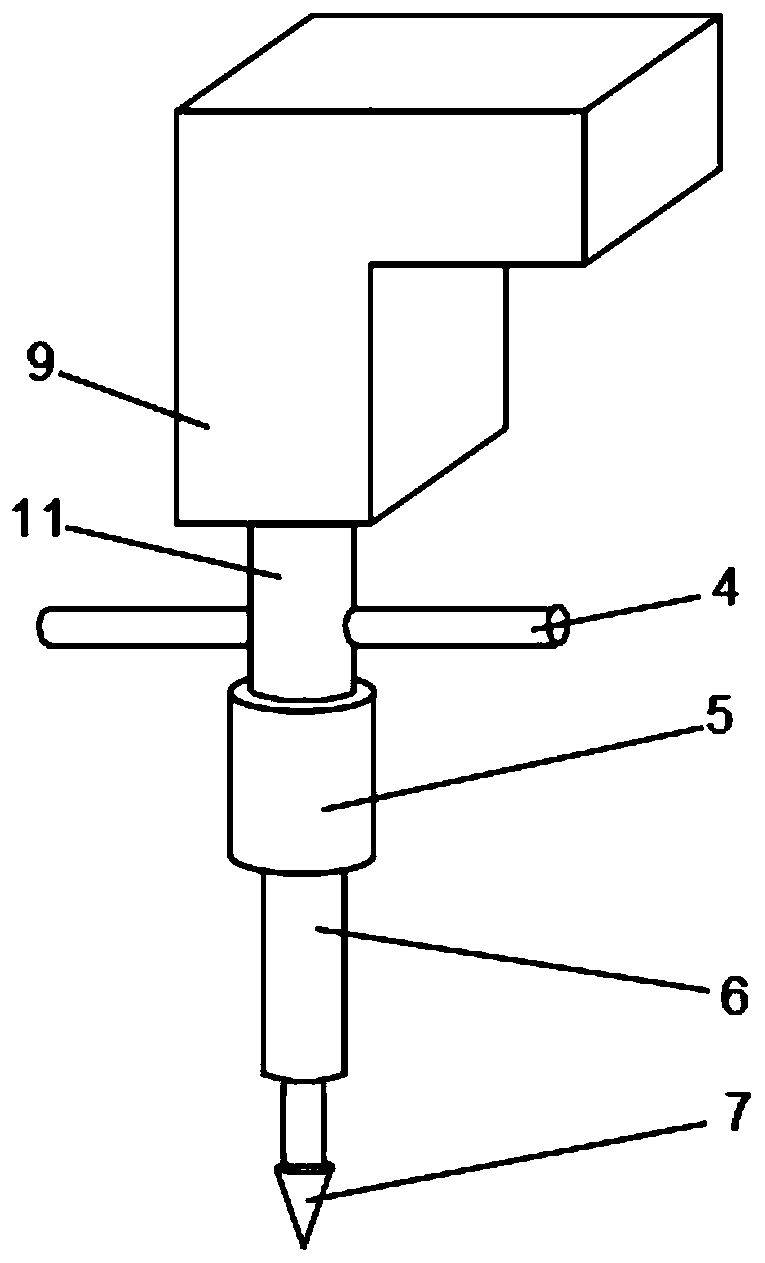

[0021] This embodiment provides an electric ground anchor hammering installation device, including a casing 9, the lower end of the casing 9 is connected with a sliding tube 11, the casing 9 and the sliding tube 11 are integrally formed and communicate with each other, and the sliding tube 11 is slidably connected with a A slider 3, a motor 1 and a gear box 8 are installed inside the housing 9, the output shaft of the motor 1 is fixedly connected to the input end of the gear box 8, and the output end of the gear box 8 is fixedly connected to a turntable 10, so The edge of the turntable 10 is rotatably connected to a connecting rod 2, the other end of the connecting rod 2 is rotatably connected to the slider 3, and the lower end of the slider 11 is slidably connected to a hammer 5, and a hammer 5 is provided below the hammer 5. There is a mounting rod 6, and a ground anchor 7 is arranged below the mounting rod 6.

[0022] When the device is working, the motor 1 rotates at a hig...

Embodiment 2

[0024] The electric ground anchor hammering installation device provided in this embodiment is basically the same as that in Embodiment 1, and the specific scheme is better.

[0025] This embodiment provides an electric ground anchor hammering installation device, including a casing 9, the lower end of the casing 9 is connected with a sliding tube 11, the casing 9 and the sliding tube 11 are integrally formed and communicate with each other, and the sliding tube 11 is slidably connected with a A slider 3, a motor 1 and a gear box 8 are installed inside the housing 9, the output shaft of the motor 1 is fixedly connected to the input end of the gear box 8, and the output end of the gear box 8 is fixedly connected to a turntable 10, so The edge of the turntable 10 is rotatably connected to a connecting rod 2, the other end of the connecting rod 2 is rotatably connected to the slider 3, and the lower end of the slider 11 is slidably connected to a hammer 5, and a hammer 5 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com