Wallpaper printing device based on foaming ink

A technology of wallpaper printing and foaming ink, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of affecting printing cost and reliability, losing printing effect, and reducing printing yield, so as to achieve convenient appearance and prevent The effect of unqualified printing quality and simplified equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

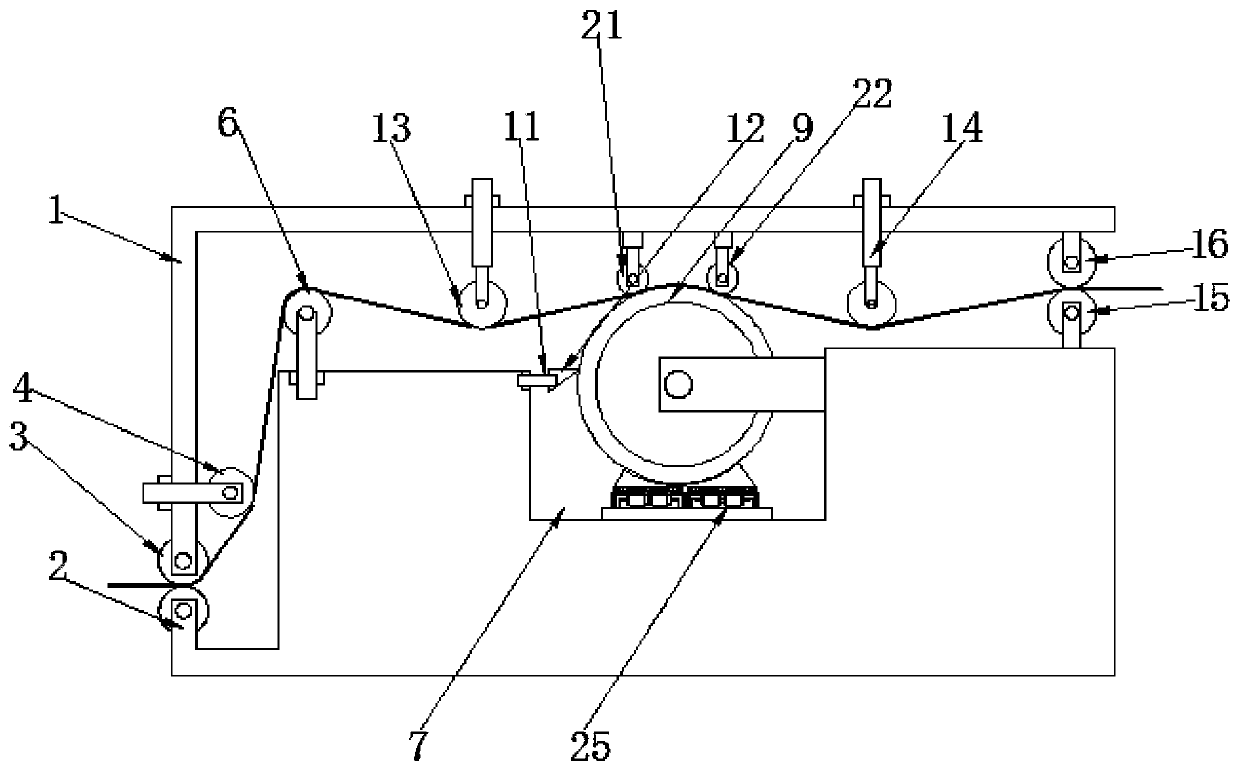

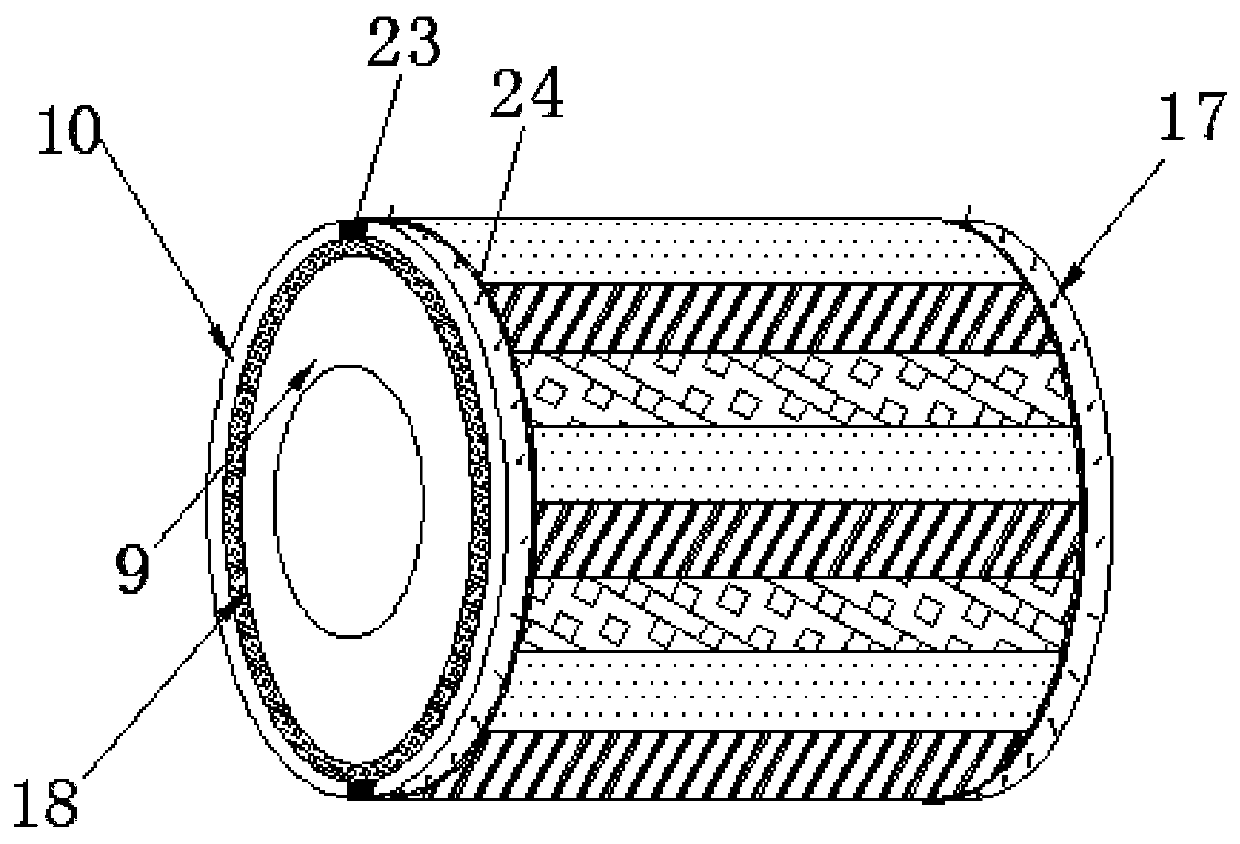

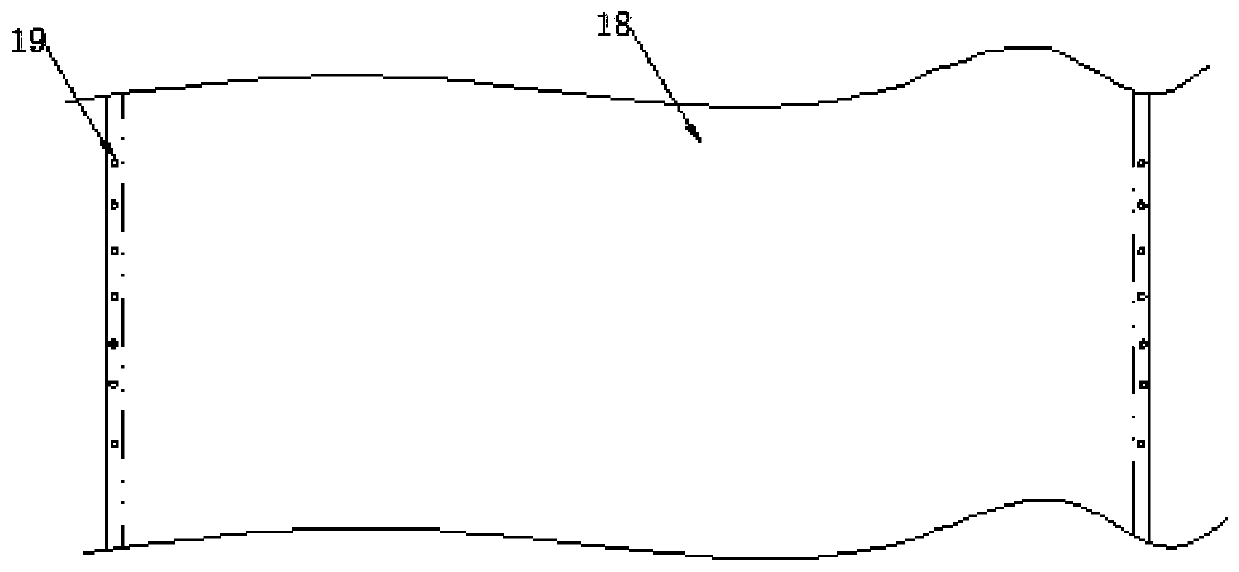

[0029] see Figure 1~5 , in an embodiment of the present invention, a wallpaper printing device based on foaming ink includes a lower support conveying roller assembly, an upper pinch roller assembly, and a printing roller 9, wherein the upper pinch roller assembly is located on the lower support conveying above the roller assembly, and the wallpaper 18 to be printed is wound on the lower support conveying roller assembly, and is pressed by the upper pinch roller assembly, and the lower support conveying roller assembly is provided with a The inking tank 7 of the roller 9, the inking tank 7 is also provided with an inking device 25 whose top is close to the printing roller; it is characterized in that;

[0030] The upper two sides of the printing roller are provided with a front pressing roller 21 and a rear pressing roller 22, and the front pressing roller and the rear pressing roller make the wallpaper of the printing position between the two close to the printing roller;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com