A green and environment-friendly synthetic method of n,n,n'-trimethylethylenediamine

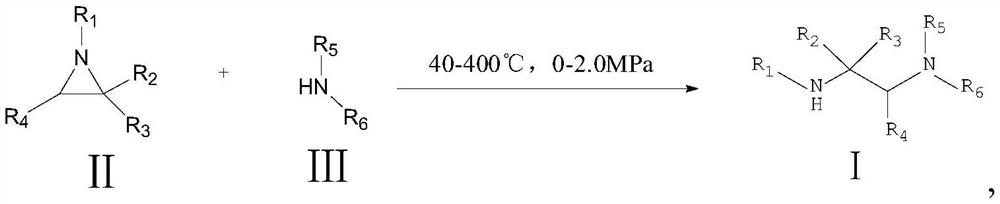

A technology of trimethylethylenediamine and a synthesis method, which can be applied in the preparation of amino-substituted functional groups, organic chemistry, etc., and can solve the problems of high salt and difficult handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

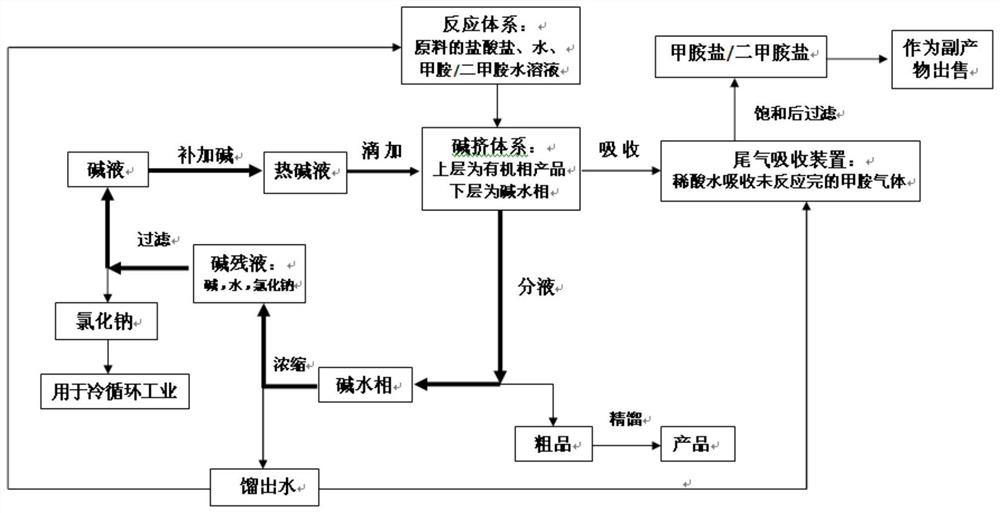

[0039] A kind of green and environment-friendly synthetic method of N,N,N'-trimethylethylenediamine, the specific preparation process flow chart is as follows figure 1 shown, including the following steps:

[0040] Preparation of S1,N,N,N'-trimethylethylenediamine hydrochloride

[0041] To a closed three-necked flask with mechanical stirring and a thermometer, add 311.5 g of a 40% dimethylamine aqueous solution with a mass concentration, and at 0° C., dropwise add 600 g of 50% 2-chloro-N- The solution of methylethylamine hydrochloride is reacted, and the reaction solution is obtained after the reaction for 2h;

[0042] S2, post-processing

[0043] The three-necked flask in S1 is connected in series with the dimethylamine absorption device with an air guide tube. The dimethylamine absorption device is equipped with 3500g of hydrochloric acid solution with a mass concentration of 25%. Sodium hydroxide aqueous solution, and the temperature of sodium hydroxide aqueous solution ...

Embodiment 3

[0055] A green and environment-friendly synthetic method of N,N,N'-trimethylethylenediamine, comprising the following steps:

[0056] Preparation of S1,N,N,N'-trimethylethylenediamine hydrochloride

[0057] To the closed three-necked flask with mechanical stirring and thermometer, add 1617.2 g of methylamine aqueous solution with a mass concentration of 40%, and at 40° C., dropwise add 750 g of N,N-dimethylamine with a concentration of 40% to the methylamine aqueous solution The aqueous solution of aminochloroethane hydrochloride is reacted, and the reaction is performed for 6 hours after the dropwise addition to obtain a reaction solution;

[0058] S2, post-processing

[0059] A methylamine absorption device was connected to the three-necked flask with an air guide, and 4000 g of a 20% hydrochloric acid solution was installed in the methylamine absorption device, and 238.0 g of an aqueous sodium hydroxide solution with a mass concentration of 70% was added dropwise to the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com