Device and method for producing graphene perovskite nano-film

A technology for nano-film and preparation device, which is applied in the field of preparation device for graphene perovskite nano-film, can solve the problems of membrane structure damage, deterioration of mechanical properties, stagnation and the like, and achieves good film continuity, good mechanical properties, Strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

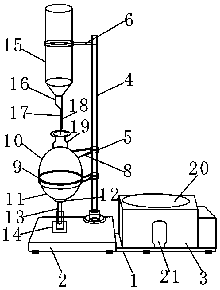

[0025] Such as figure 1 Shown, a kind of preparation device of graphene-based perovskite type nanocrystalline thin film comprises base 1, and base plate 2 and horse boiling furnace 3 are respectively fixedly installed on the two ends of described base 1 upper surface, and described base plate 2 is fixedly installed There is a longitudinal support rod 4, and the longitudinal support rod 4 is fixedly equipped with three rotating shafts 5, the rotating shaft 5 at the top is equipped with a drip tube 7 through the first clamp arm 6, and the two rotating shafts 5 at the bottom pass through the second clamp arm 8 The sleeve ring 9 and the protective cover 10 are respectively installed, and different devices are respectively installed through the holding effect of the rotating shaft 5 and the first clamping arm 6 and the second clamping arm 8. The rotating shaft 5 can realize 360° rotation on the plane, The bottom of the protective cover 10 coincides with the edge of the sleeve ring ...

Embodiment 2

[0034] The difference with embodiment 1 is:

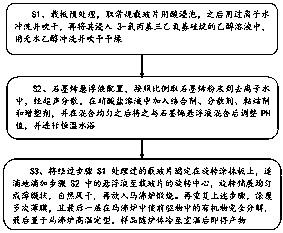

[0035] Such as figure 2 Shown, the present invention also provides a kind of manufacture method of graphene-based perovskite type nanocrystalline film, comprises the following steps:

[0036] S1, carrier plate pretreatment, take a conventional glass slide and put it into 30% H with a volume ratio of 3:7 2 o 2 solution and 98% H 2 SO 4 Soak the mixed solution at 90°C for 1.5h, then rinse it with deionized water and dry it, then immerse it in the ethanol solution of 3-aminopropyltriethoxysilane for 0.7h, take it out, rinse it with absolute ethanol and blow it dry. Dry, and then put it in an oven at 110°C for 2.3 hours;

[0037] S2. Graphene suspension configuration, take graphene powder into deionized water according to the proportion, and obtain a stable suspension after ultrasonic dispersion for 1.5h, add complexing agent, dispersant, viscose in 0.12mol / L nitrate solution in sequence A binder and a plasticizer, and after mix...

Embodiment 3

[0041] The difference with embodiment 1 and embodiment 2 is:

[0042] Such as figure 2 Shown, the present invention also provides a kind of manufacture method of graphene-based perovskite type nanocrystalline film, comprises the following steps:

[0043] S1, carrier plate pretreatment, take a conventional glass slide and put it into 30% H with a volume ratio of 3:7 2 o 2 solution and 98% H 2 SO 4 Soak the mixed solution at 100°C for 2 hours, then rinse it with deionized water and dry it, then immerse it in the ethanol solution of 3-aminopropyltriethoxysilane for 1 hour, take it out, rinse it with absolute ethanol and blow it dry, Then put it into an oven at 120°C to dry for 2.5 hours;

[0044] S2. Graphene suspension configuration, take graphene powder into deionized water according to the proportion, and obtain a stable suspension after ultrasonic dispersion for 2 hours, add complexing agent, dispersant, and bonding agent in 0.15mol / L nitrate solution in sequence agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com