Pipeline anti-displacement anti-floating mechanism and pipeline anti-floating construction method

A pipe and displacement technology, which is applied in the direction of pipe laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems that drainage pipes and culverts are easy to move, etc., and is conducive to popularization and application, with reasonable device structure and improved application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

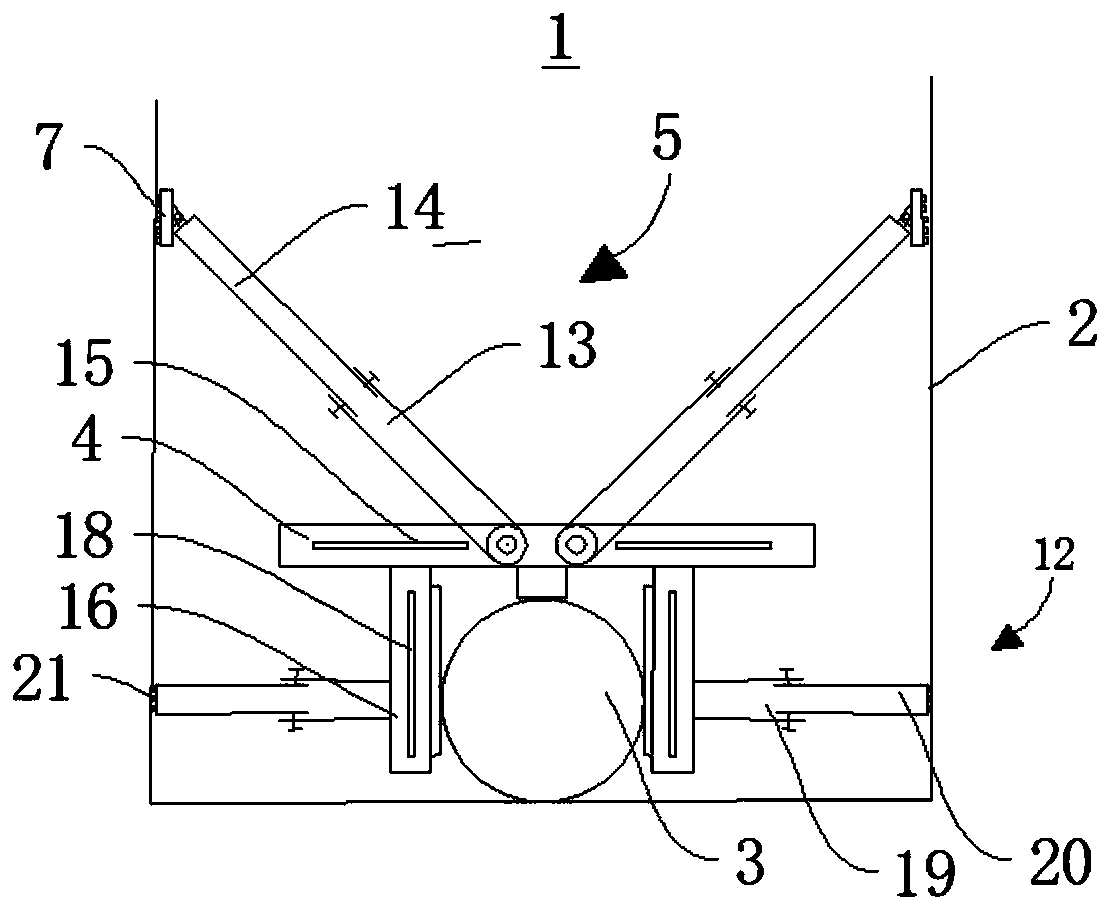

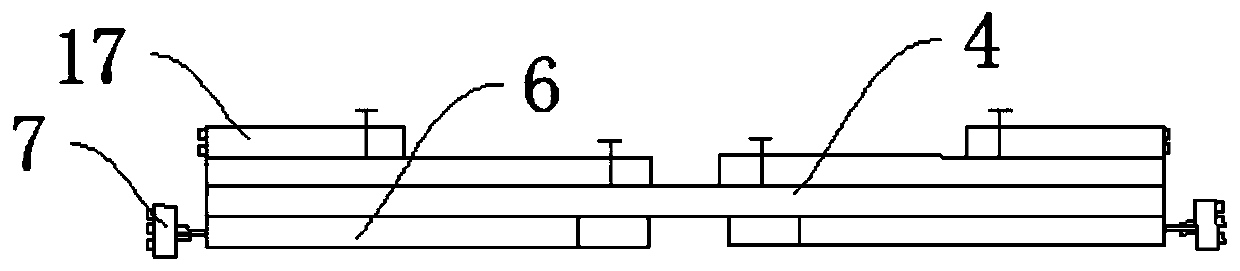

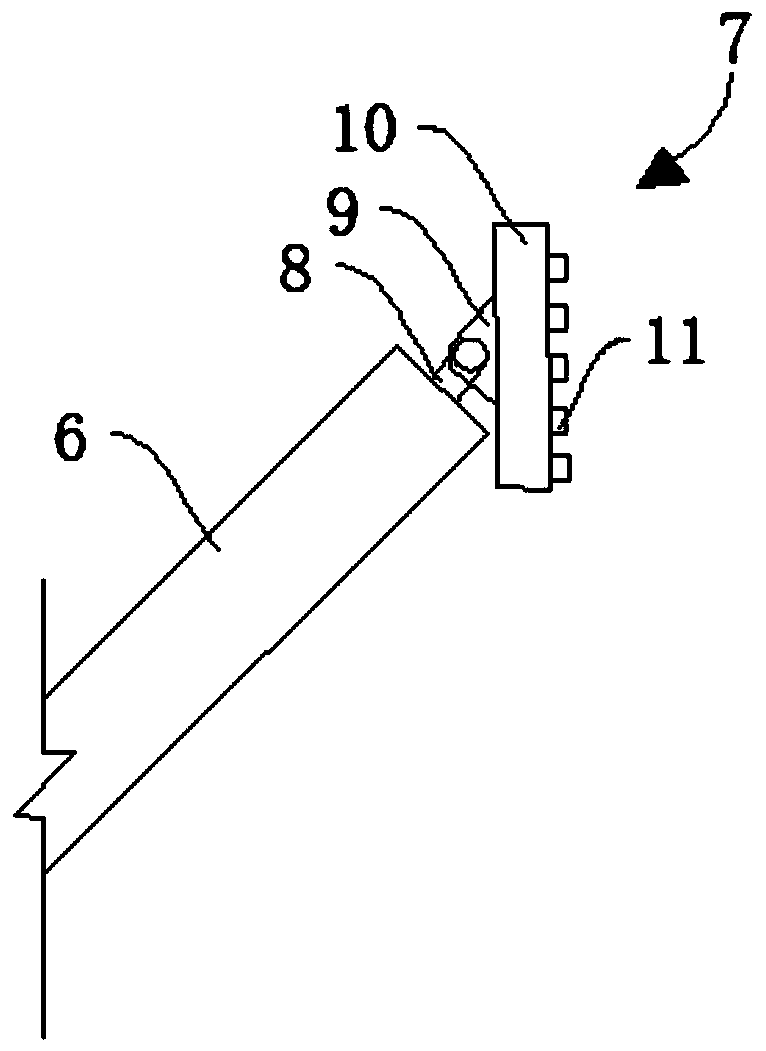

[0038] Please refer to figure 1 , with reference to figure 2 and image 3 , the application provides a pipeline anti-displacement and anti-floating mechanism 1, which is used to prevent the pipeline 3 from moving in the foundation pit 2, which mainly includes a cross bar 4, two sets of brace assemblies 5 and two sets of limit assemblies 12; 4. It is horizontally arranged directly above the pipe 3, and at a certain distance from the pipe 3. A liner is installed in the middle of the cross bar 4. The liner is made of hard rubber to protect the pipe 3; the two sets of diagonal braces The assembly 5 is arranged on the cross bar 4 in an inverted splayed shape. Each set of brace assemblies 5 includes a brace pipe 6 and a positioning structure 7. One end of the brace pipe 6 is hinged to the middle of the cross bar 4, and the other end abuts on the On the inner side wall of the foundation pit 2, two diagonal bracing pipes 6 are arranged in an inverted figure-eight shape. Simultaneo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com