Automatic programming method for processing finish machining allowance of die

A technology of automatic programming and machining allowance, applied in the direction of simulator, program control, general control system, etc., can solve the problems of low processing efficiency and high processing cost, and achieve the goal of improving processing efficiency, high universality, and reducing processing errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

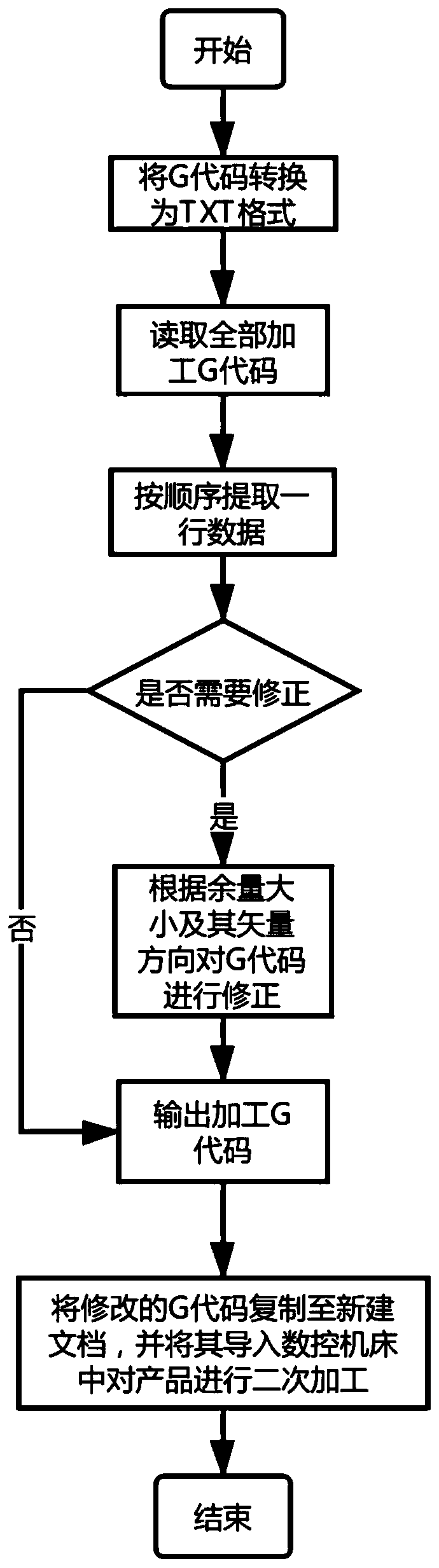

[0064] Such as figure 1 As shown, an automatic programming method for processing mold finishing allowance, including the following steps:

[0065] S1. Convert the processing G code from ptp format to TXT format to form a processing program TXT file, and install the corresponding language environment;

[0066] In this embodiment, step S1 converts the processed G code from ptp format to TXT format, and installs the corresponding language environment as follows:

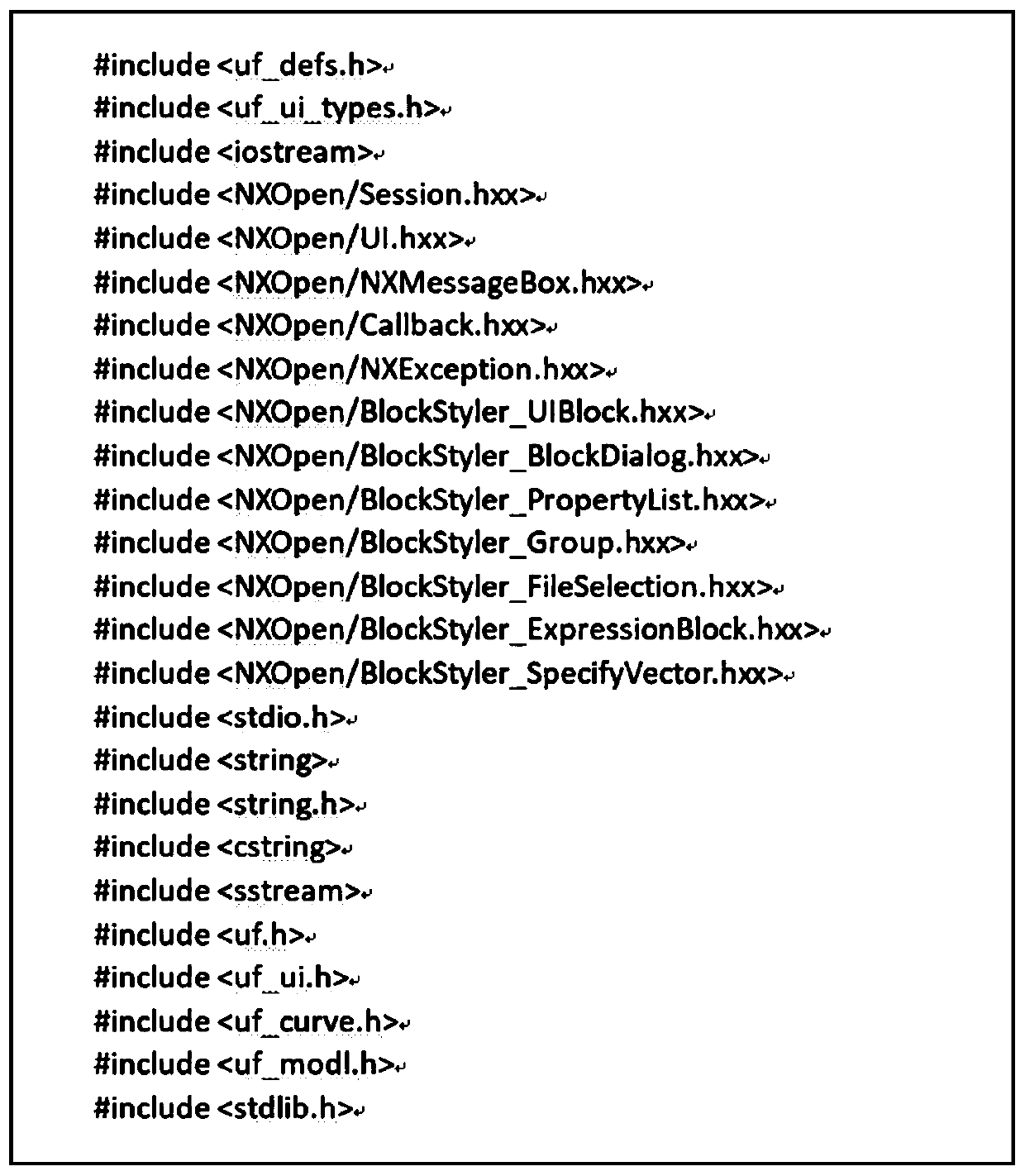

[0067] Use the CNC programming software to export the processing G code, open it in Notepad, and save it in TXT format. Then install Microsoft Visual Studio 2010, where the header files needed for programming are as follows figure 2 shown.

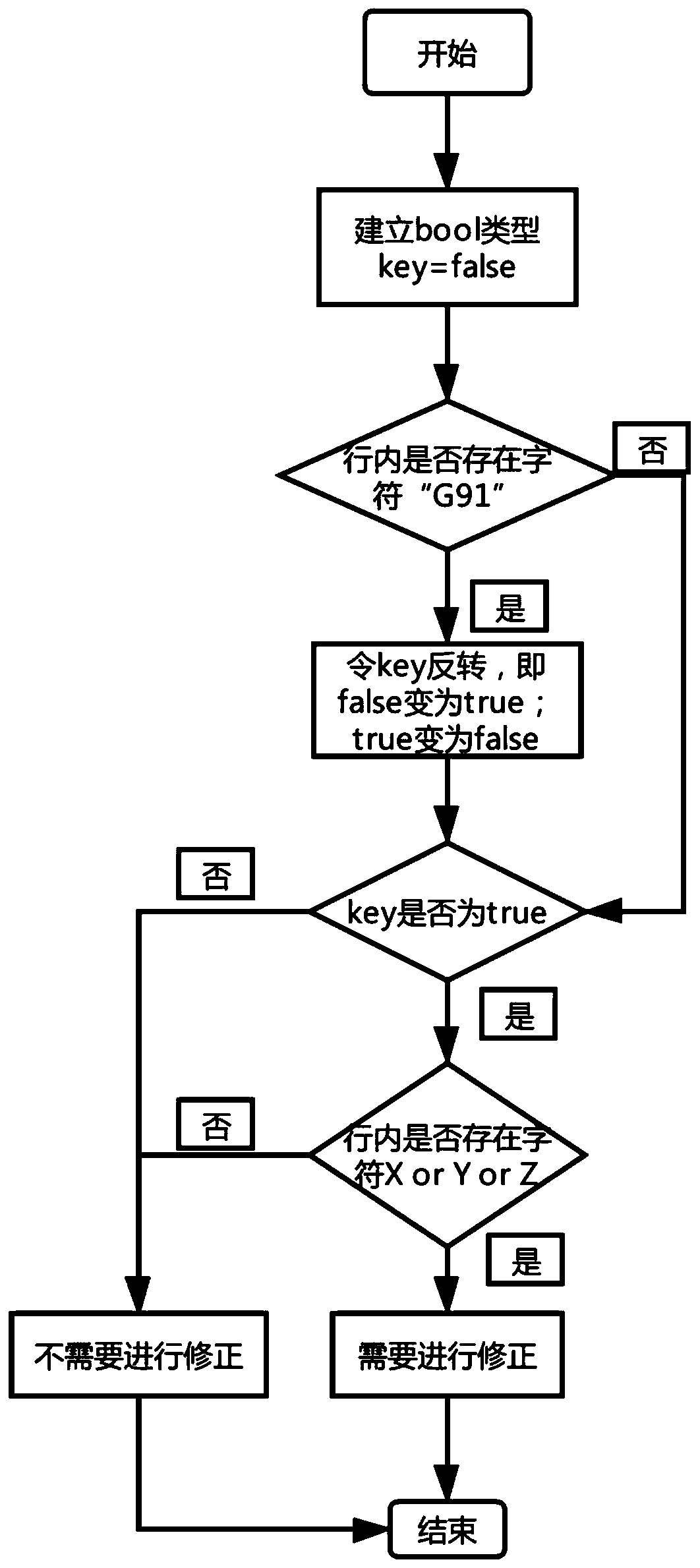

[0068] S2. Read all the information in the TXT file of the G code as fol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap