Needle wire stamping die device with sawtooth tail end and stamping die method

A zigzag, needle-wire technology, applied in the field of medical devices, can solve the problems of low cost and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

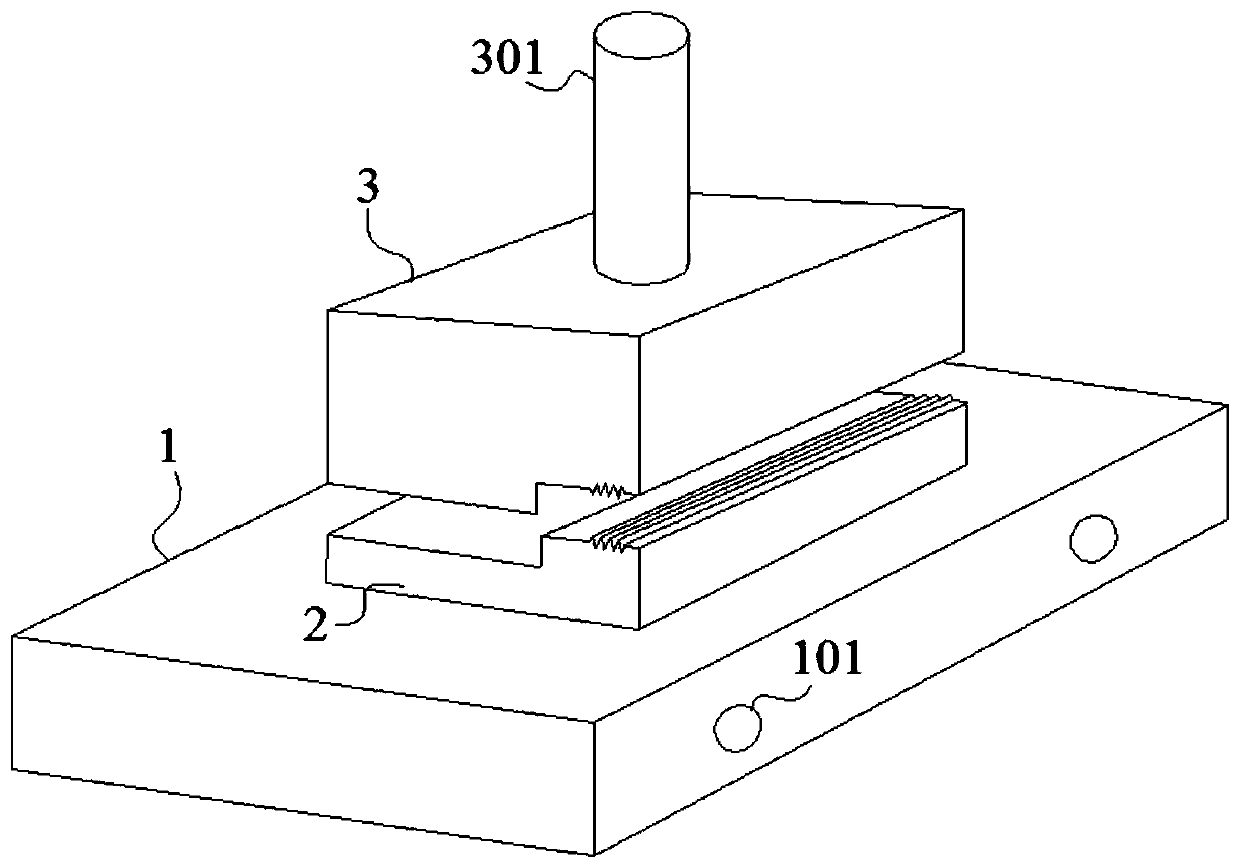

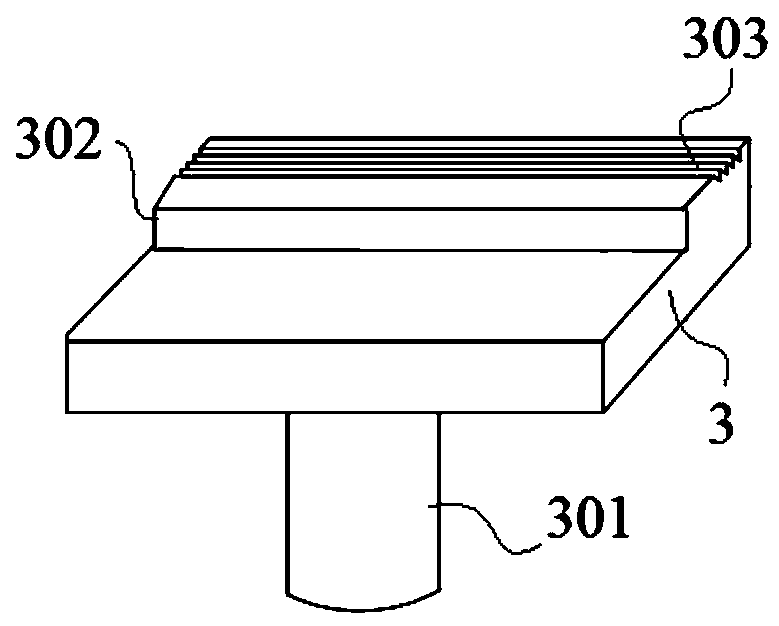

[0035] A kind of tail end of the present embodiment is a zigzag needle thread die device and die method, such as figure 1 As shown, it includes a workbench 1, a lower mold 2 and an upper mold 3. The lower mold 2 is fixedly installed on the upper surface of the workbench 1, and the front and rear surfaces of the workbench 1 are symmetrically provided with bolt holes 101. The bolts The holes 101 are matched with bolts to fix the workbench 1 and the foundation; the upper mold 3 is arranged above the lower mold 2 in an adaptive manner, and the upper surface of the lower mold 2 and the lower surface of the upper mold 3 are adapted in a transverse direction The lower sawtooth groove 202 and the upper sawtooth groove 303 are provided, the needle wire 4 to be formed is placed between the upper mold 3 and the lower mold 2, and the upper mold 3 is pressed into the lower mold 2 in an adaptive manner, In order to realize the zigzag shape of the needle tail 401 and to solve the problem tha...

Embodiment 2

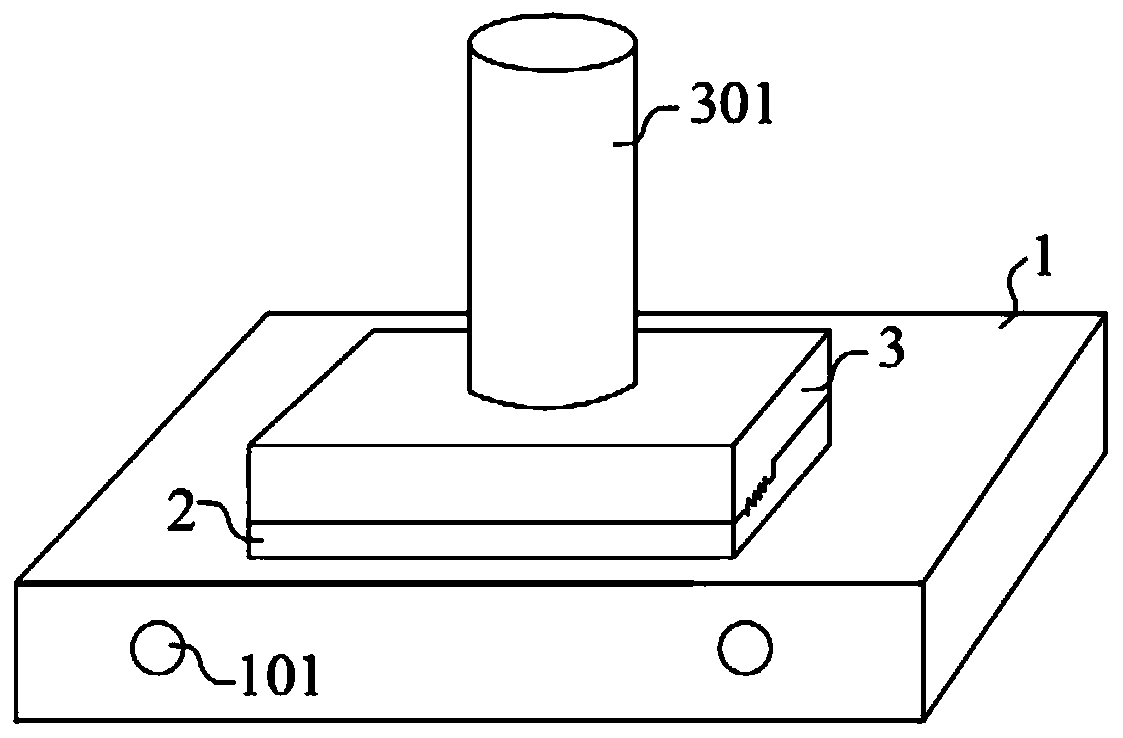

[0037] A kind of tail end of this embodiment is a zigzag needle thread die device and die method, the basic structure is the same as embodiment 1, the differences and improvements are as follows: figure 2 As shown, the middle part of the upper surface of the upper mold 3 is fixedly connected with a handle 301, and the handle 301 is fixedly connected on the outer frame of the device, and the handle 301 is connected with the lifting mechanism on the outer frame of the device, and the handle is driven up and down by the lifting mechanism. Move to realize the pressing and lifting of the upper mold 3, so as to complete the molding of the needle tail 401.

Embodiment 3

[0039] A kind of tail end of this embodiment is a zigzag needle thread die device and die method, the basic structure is the same as embodiment 2, the differences and improvements are as follows: figure 2 As shown, the middle part of the upper surface of the upper mold 3 is fixedly connected with a handle 301 , and the handle 301 is moved up and down by holding the handle 301 to realize the pressing and lifting of the upper mold 3 , thereby completing the forming of the needle tail 401 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com