Elevator landing door system

A technology for landing doors and elevators, which is applied to elevators in buildings, fastening devices for wings, fastening devices for buildings, etc. Simple, lower installation requirements, simple effect on sill production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

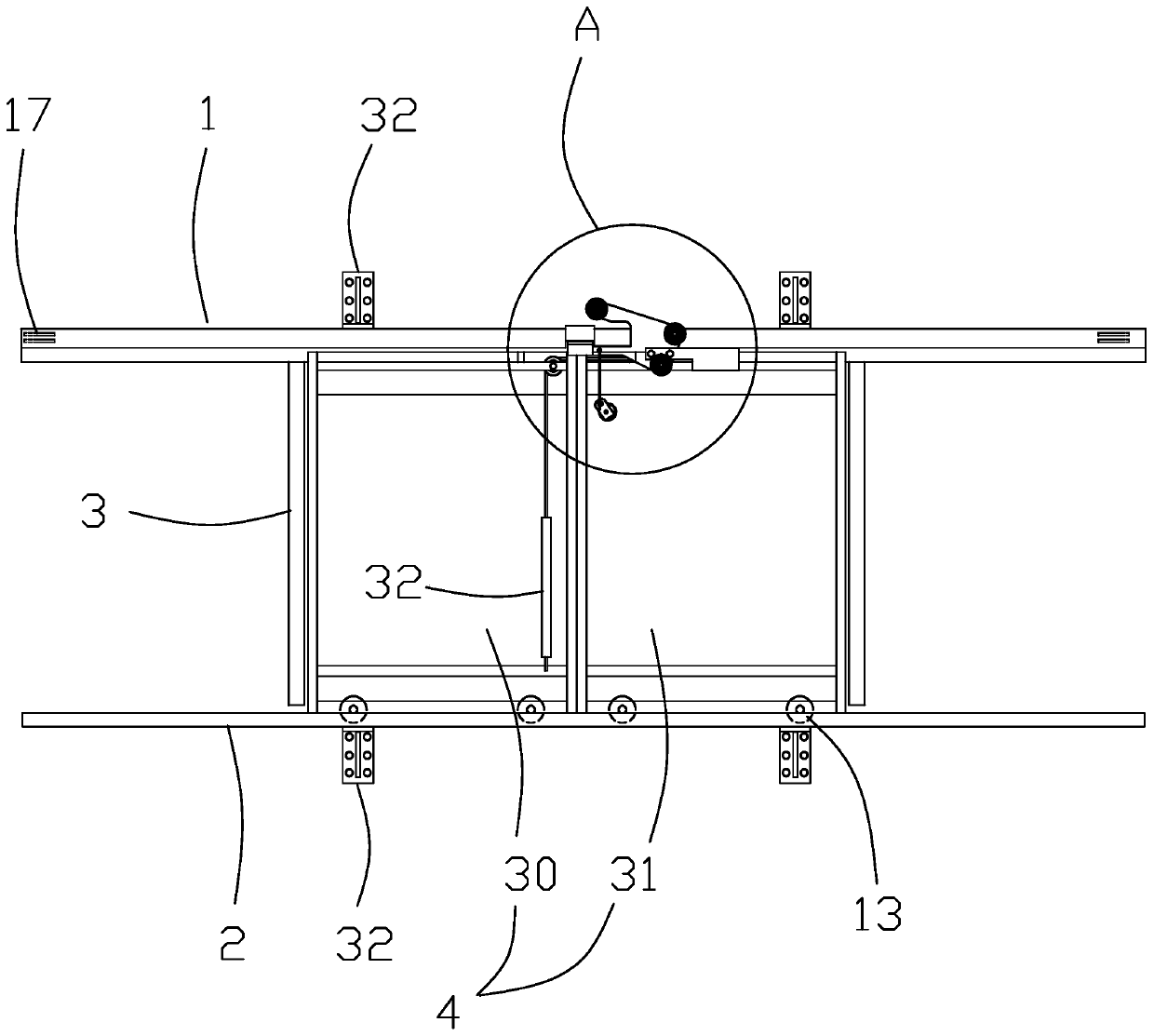

[0025] This embodiment is an elevator landing door system, such as figure 1 As shown, the upper sill 1, the sill 2, the uprights 3 arranged between the upper sill and the sill, and the left and right door panels 4. The upper sill and the sill are fixed on the hoistway wall by an L-shaped fixing frame, and the lower end of the column is fixed to the sill.

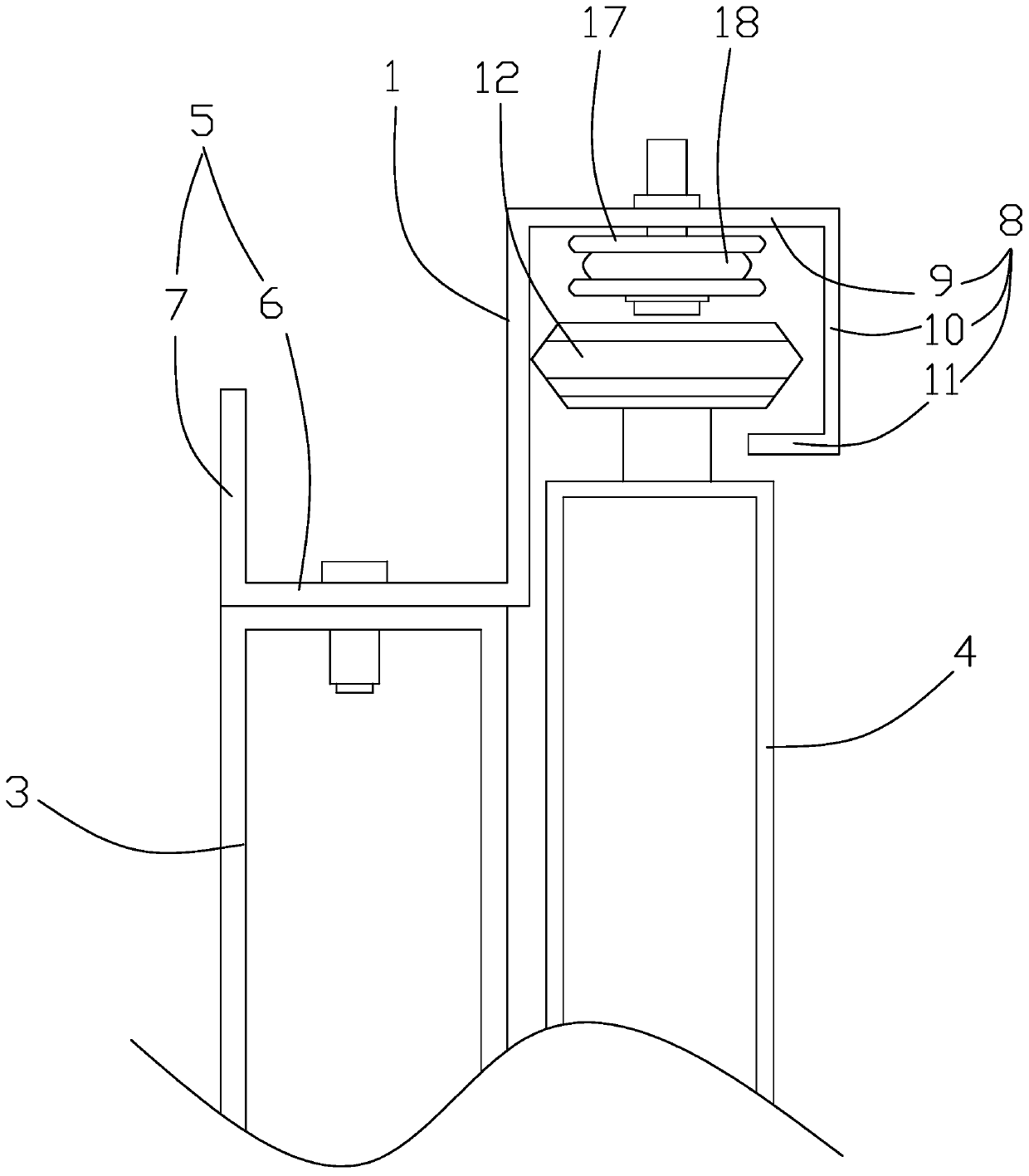

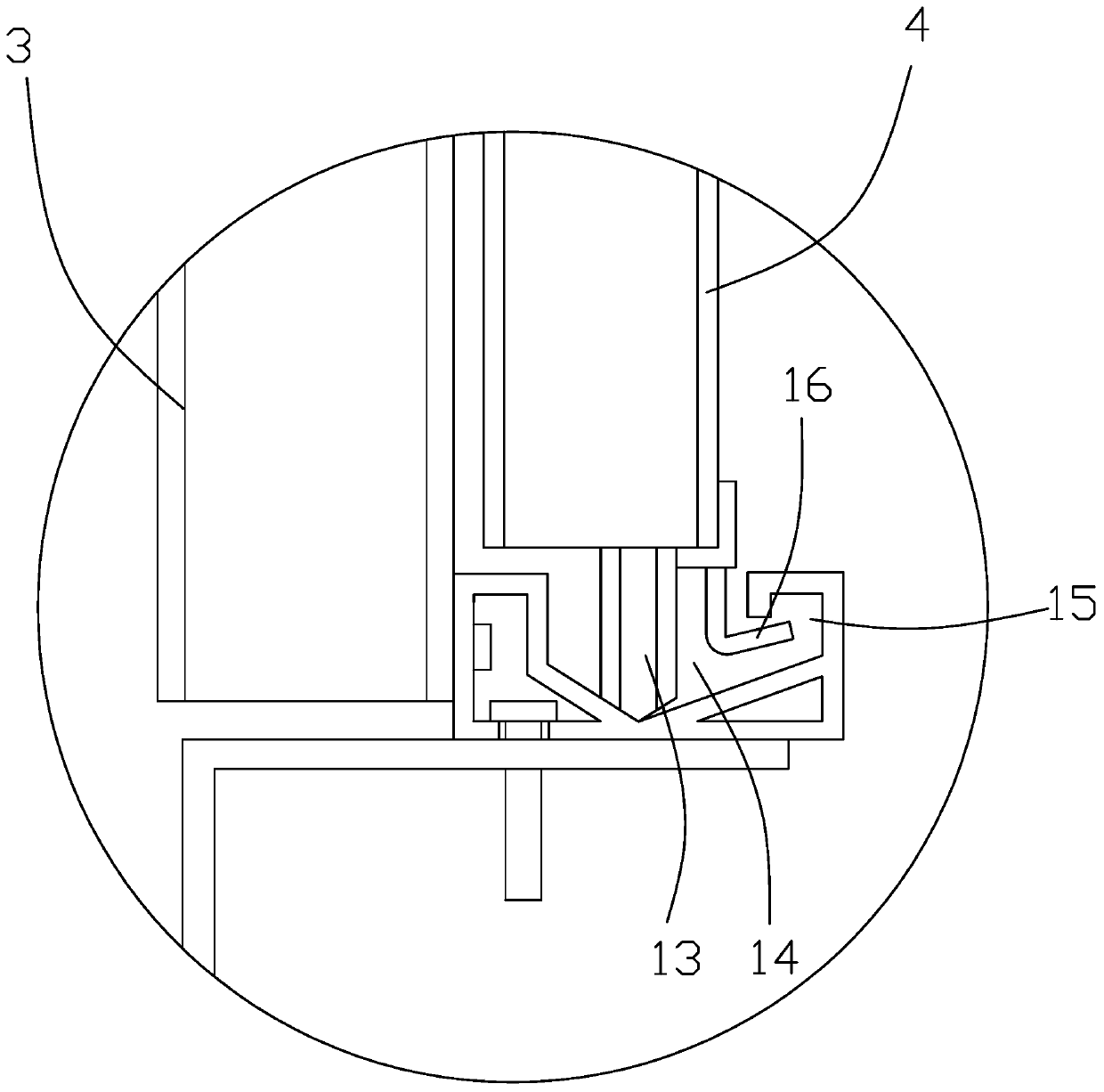

[0026] Such as figure 2 As shown, the lower end of the upper sill is bent to one side of the column to form a back plate 5. The back plate includes a fixed plate 6 and a front plate 7. The fixed plate and the front plate are perpendicularly connected to form an L-shaped structure, and the fixed plate is vertically connected to the upper sill. A blind rivet nut is built in the upper end of the column, and the fixing plate is matched with the upper end of the column and fixed by a combination bolt. The upper end of the upper sill extends and bends toward the left and right door panels to form the guide groove 8. The guide groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com