Bottom pouring steel ladle

A technology of ladle and bottom injection, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of inconvenient operation for workers, and achieve the effect of improved safety and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

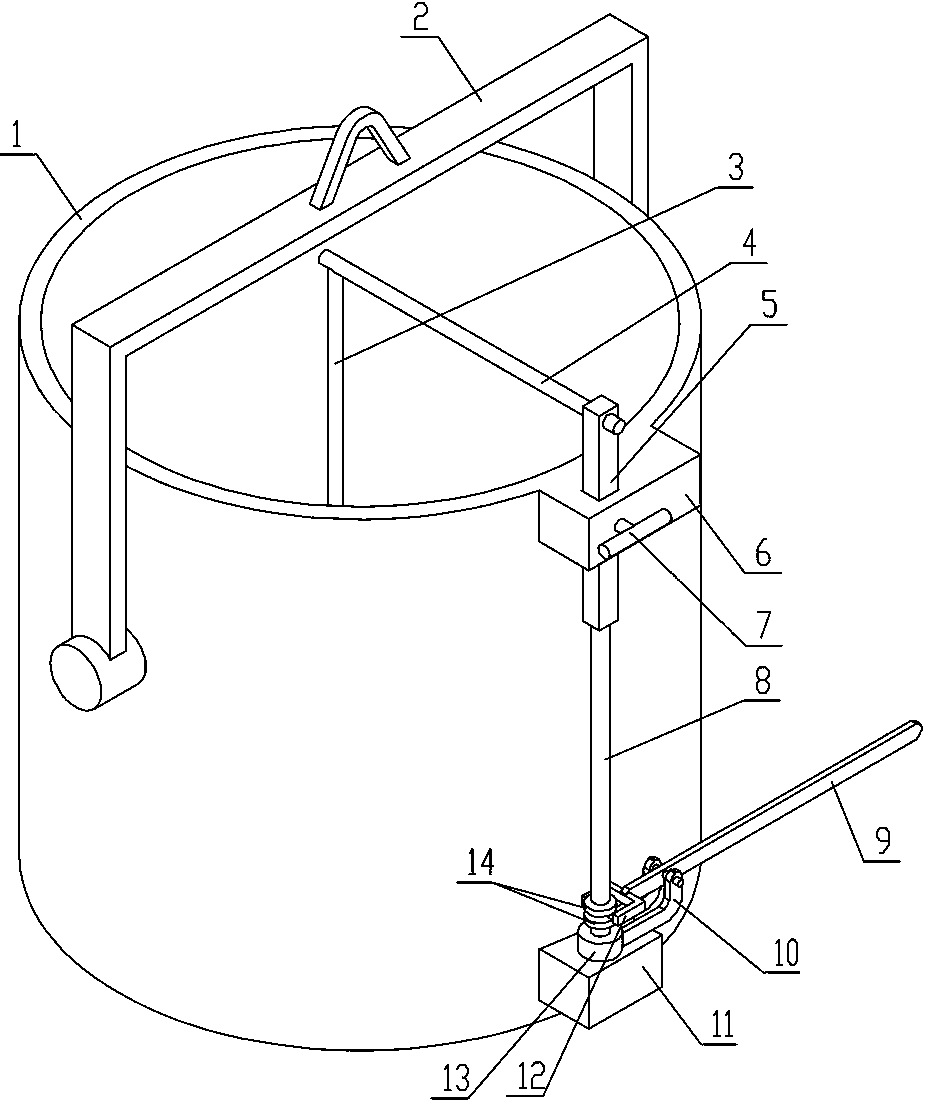

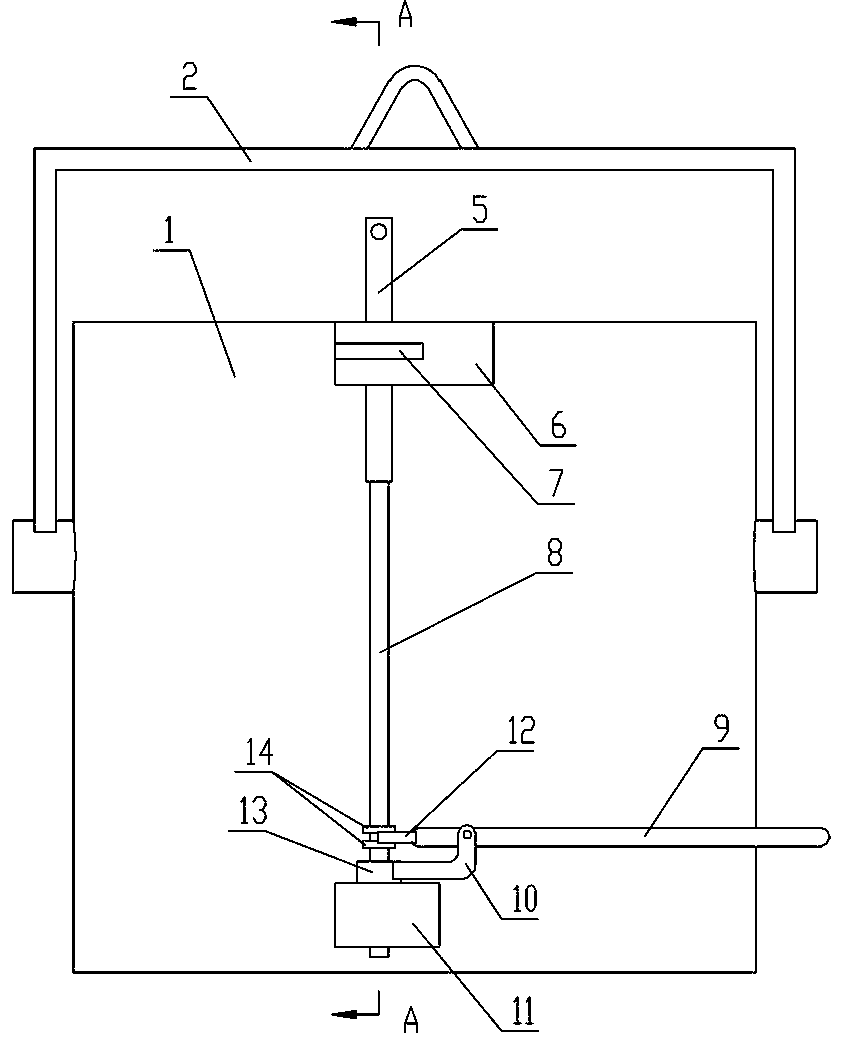

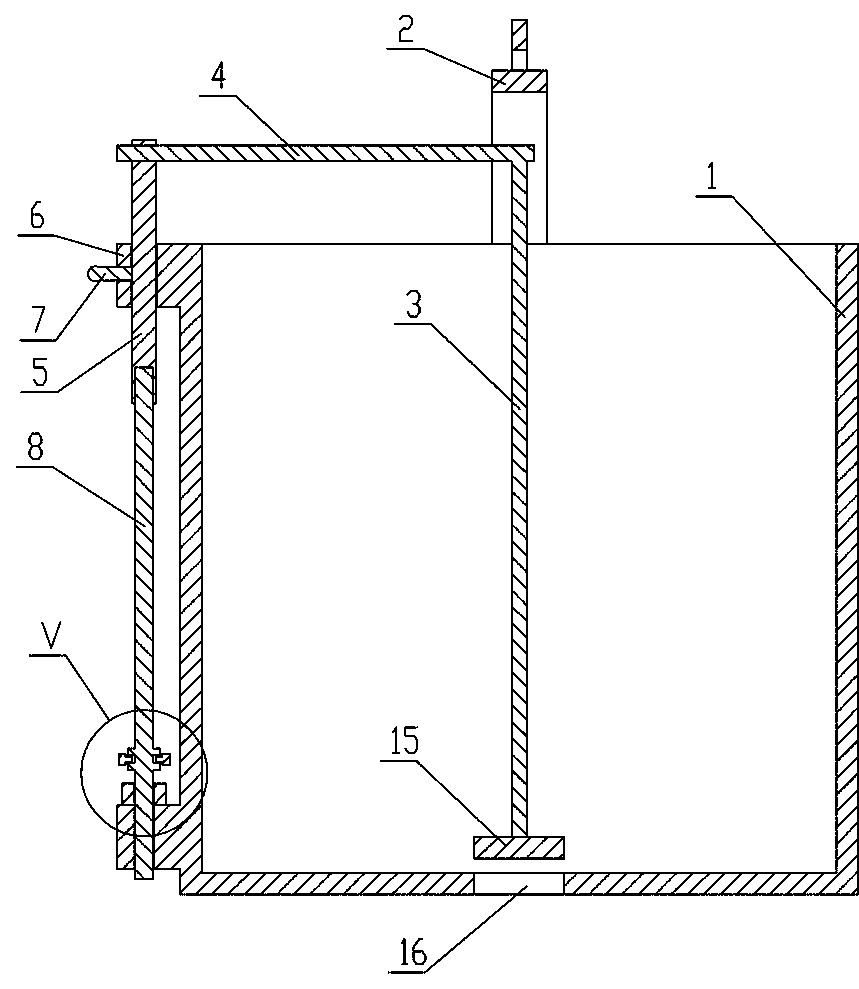

[0012] see Figure 1-4 , the present embodiment comprises a gantry 2, the two ends of the gantry 2 are provided with vertically downward support plates, a ladle 1 is arranged between the two support plates, a pouring hole 16 is provided at the bottom of the ladle 1, and a pouring hole 16 is installed above the pouring hole 16. There is a sealing plate 15, and a set of lifting device is connected to the top of the sealing plate 15. The lifting device includes a support plate A11 fixed on the lower part of the outer wall of the ladle 1. The ladle 1 is fixed above the support plate A11 with a rectangular The support plate B6 of the through hole, a circular through hole is arranged in the middle of the support plate A11, a collar 13 is arranged above the circular through hole, and a vertical cylindrical ejector rod 8 is housed in the collar 13, and the ejector rod 8 The bottom passes through the circular through hole of the support plate A11, and a bracket 10 is fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com