Threading clamp

A threading jig and axis technology, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of reduced production capacity, long time-consuming manual threading, etc., and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

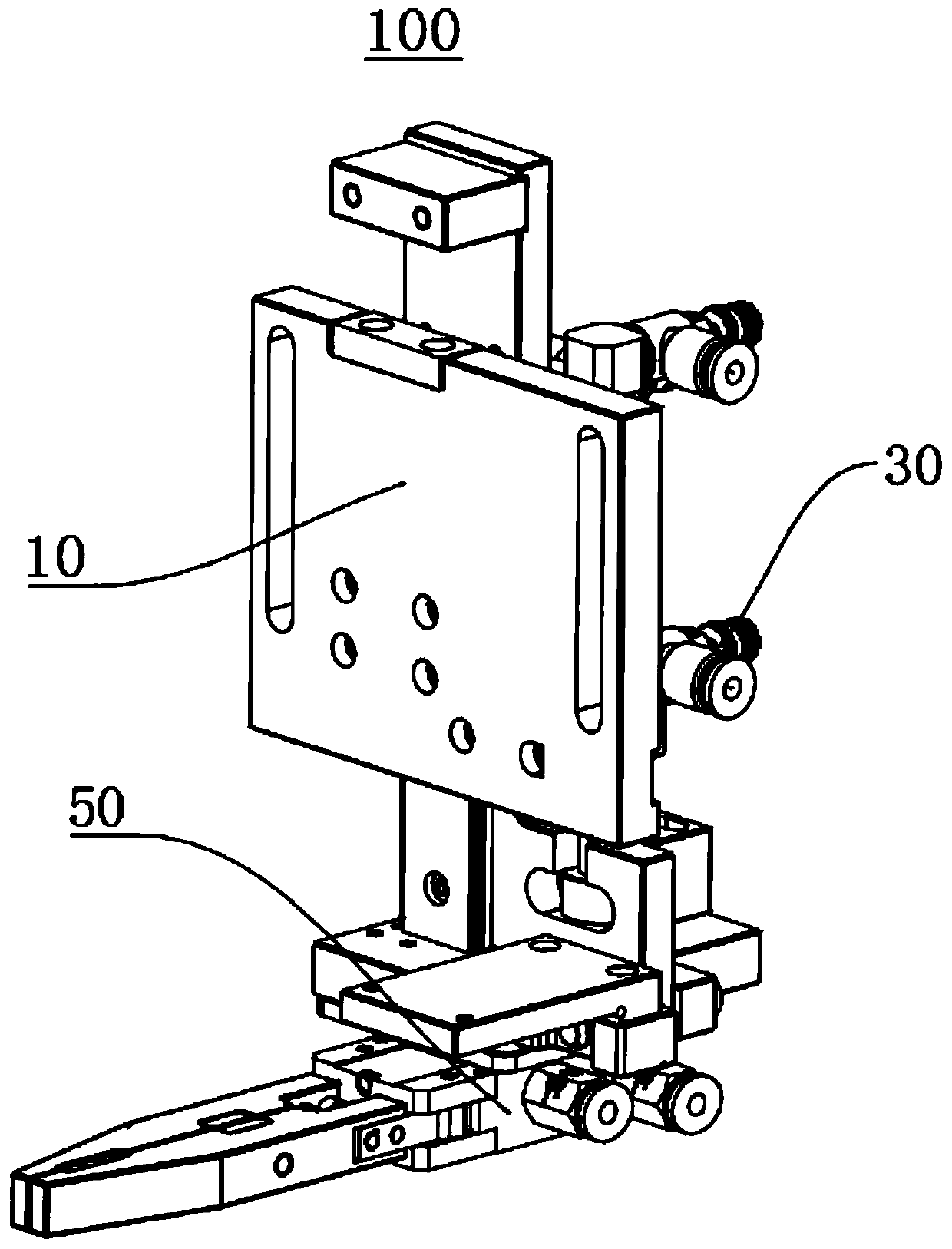

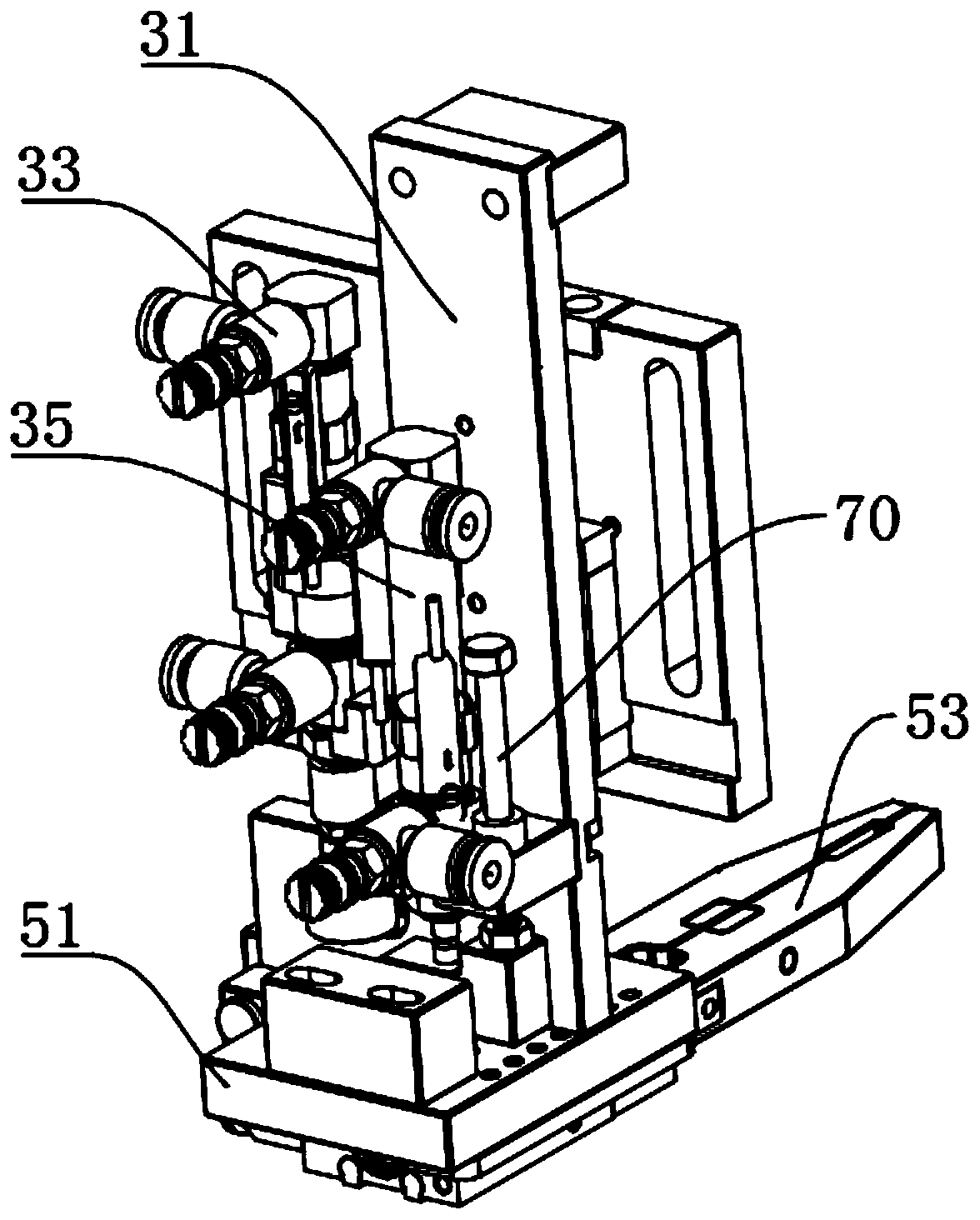

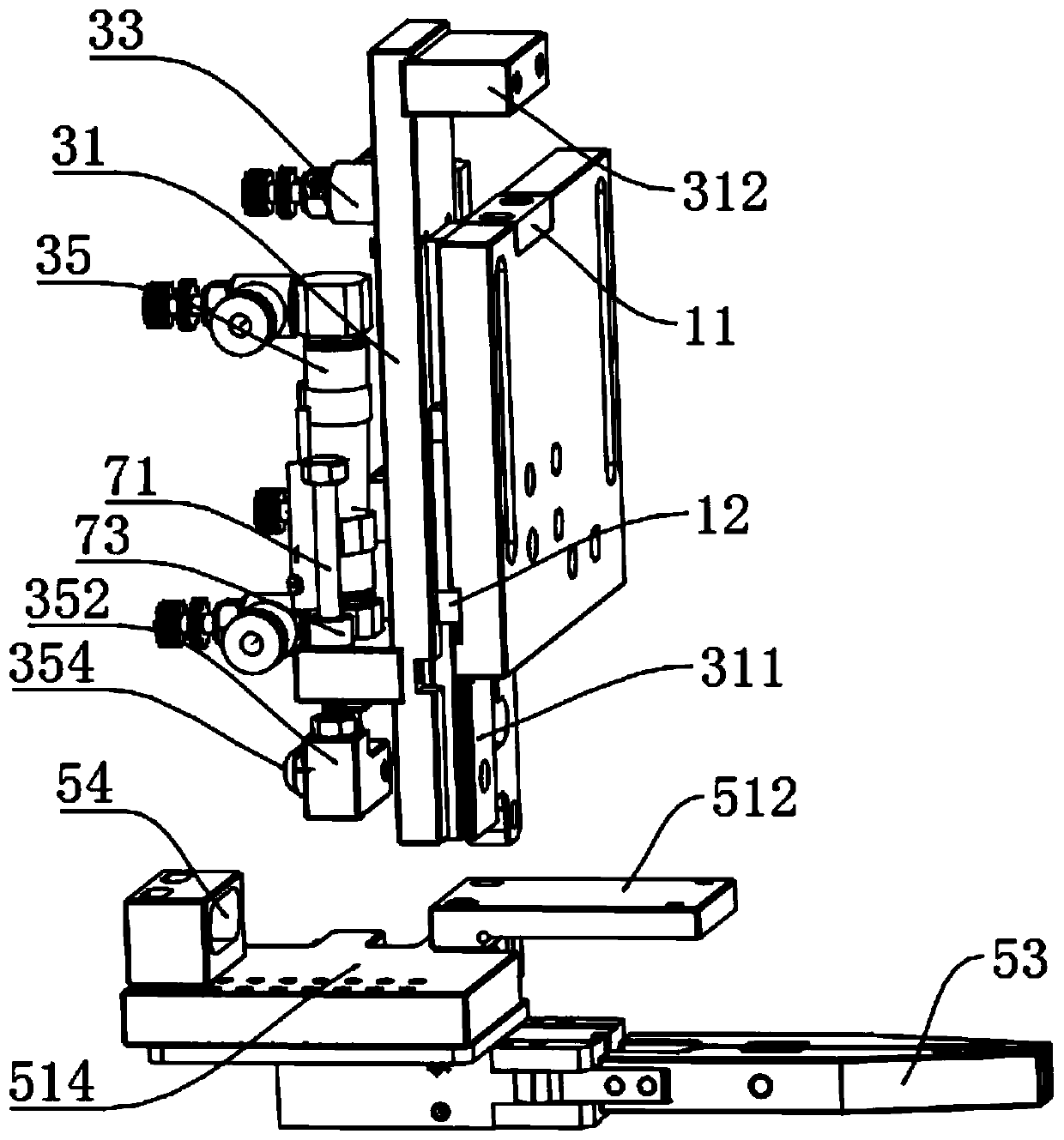

[0044] Please refer to Figure 1 to Figure 9 , the embodiment of the present application provides a threading fixture 100, including a first base 10, a driving mechanism 30 and a clamping device 50;

[0045] The driving mechanism 30 is arranged on the first base 10, and the clamping device 50 is connected to the output end of the driving mechanism 30. The clamping device 50 is used to clamp the thread to be threaded. The driving mechanism 30 can drive the clamping device 50 to translate and rotate.

[0046] Wherein, the threading clamp 100 can rely on the clamping device 50 to clamp and fix the thread to be threaded, and then realize the bending and movement of the thread to be threaded through the driving mechanism 30, thereby eliminating the need for manual threading and solving corresponding problems.

[0047] Please combine figure 2 and Figure 4Specifically, in this embodiment, the driving mechanism 30 includes a second base 31, a first driving device 33 and a second d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com