Double telescopic hydraulic flexible shield support frame and method

A flexible shielding support, double telescopic technology, applied in the direction of mine roof support, earthwork drilling, mining equipment, etc., can solve the problems of poor safety, low labor efficiency, high cost, and achieve the effect of increasing support strength and facilitating transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

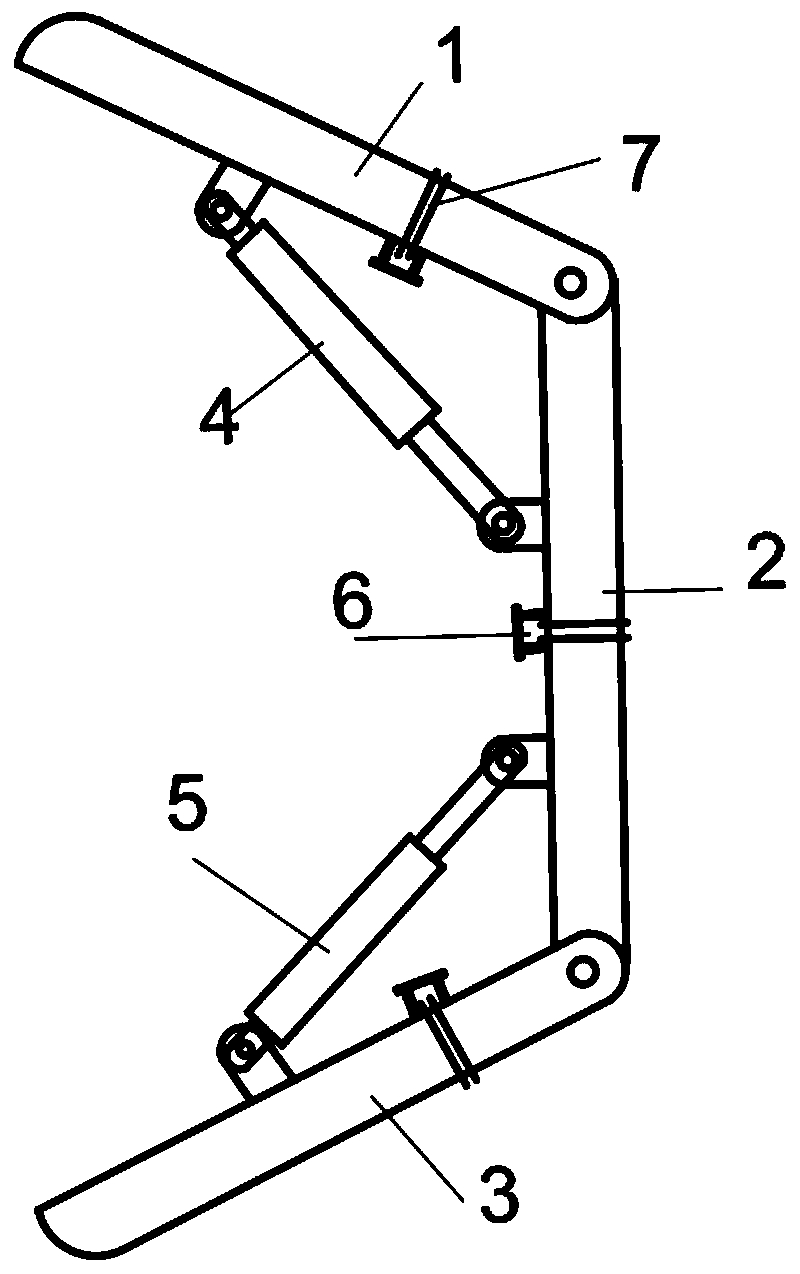

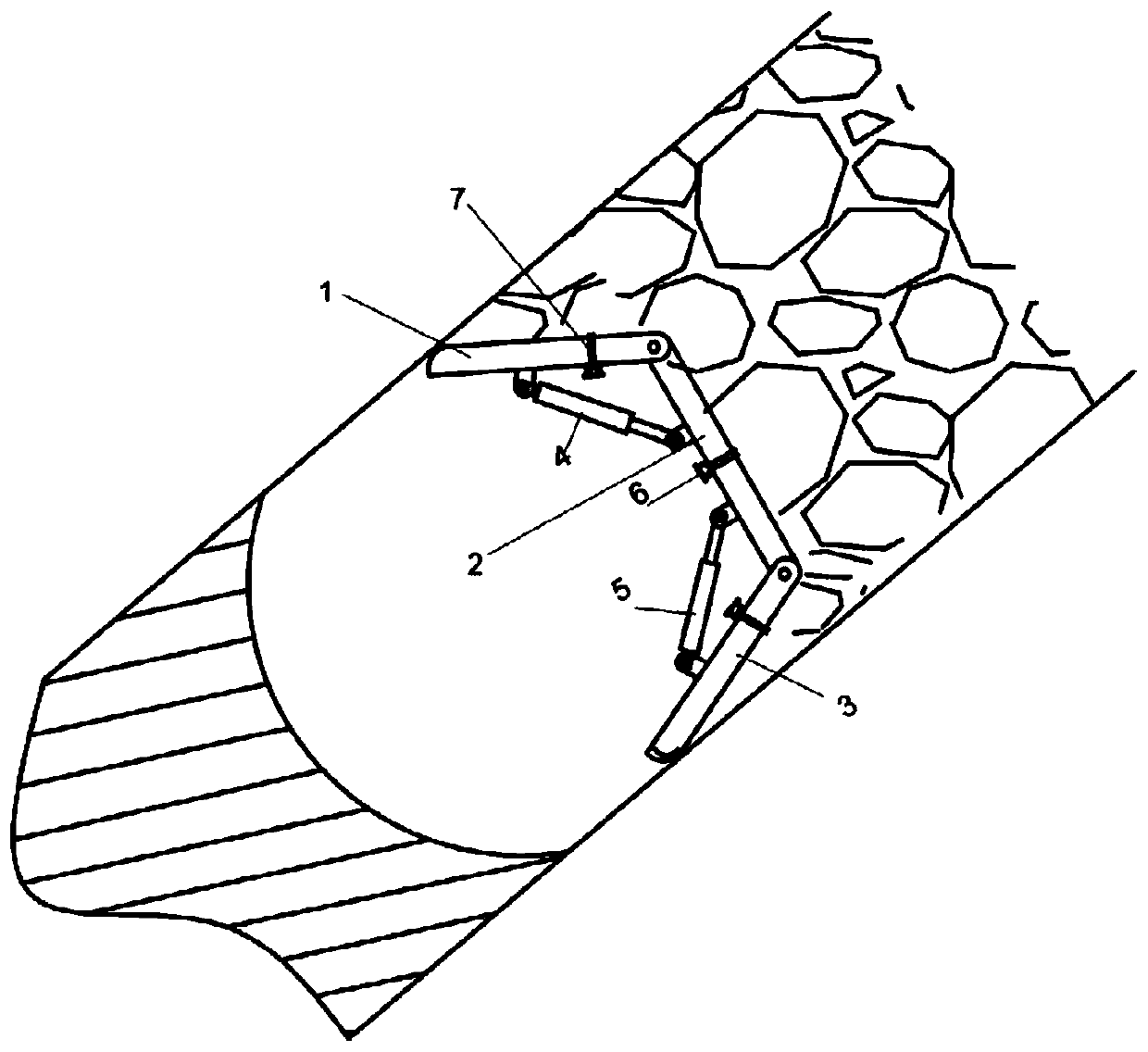

[0030] like figure 1 As shown, a double telescopic hydraulic flexible shielding support includes an upper top plate 1, a shielding beam 2, a first jack 4, a second jack 5, a lower support plate 3, a rope hole 6 and a wire rope 7. The said The upper top plate 1, the shield beam 2 and the lower support plate 3 are connected end to end in turn by hinges. In this embodiment, the upper ceiling plate, the shield beam and the lower support plate are made of 12# steel rolled steel plates, with a width of 125mm and a thickness of 60mm. The length of the shield beam is 1200mm, the length of the cover beam is 1150mm, and the length of the lower support plate is 1200mm.

[0031] The first jack 4 and the second jack 5 are respectively movably installed between the upper top plate 1 and the shielding beam 2 and between the shielding beam 2 and the lower support plate 3, and both ends of the first jack are hinged at a distance from each other. The two ends of the second jack are hinged at 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com