A Broadband Vibration and Noise Reduction Metamaterial Multi-span Beam Structure

A technology of vibration and noise reduction, metamaterials, applied in the direction of shock absorber, spring/shock absorber functional characteristics, shock absorber, etc. To achieve the effect of widening the frequency range of the wide band gap, simple structure, and improving the effect of vibration reduction and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

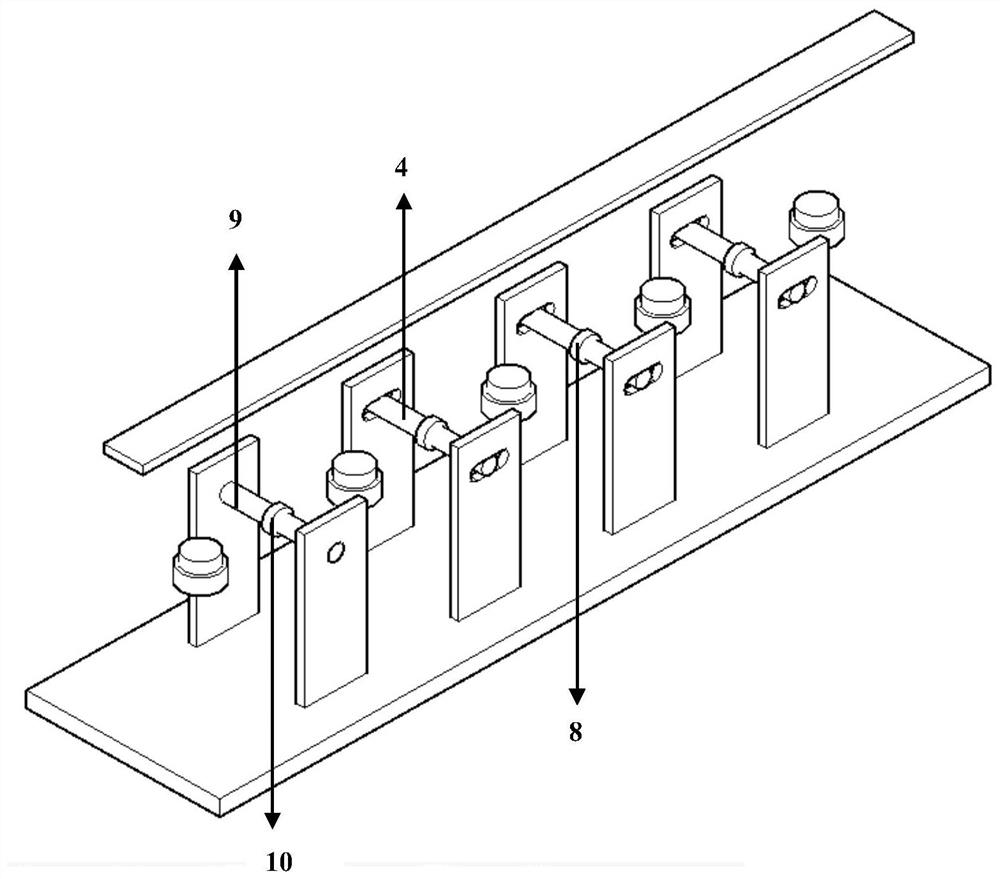

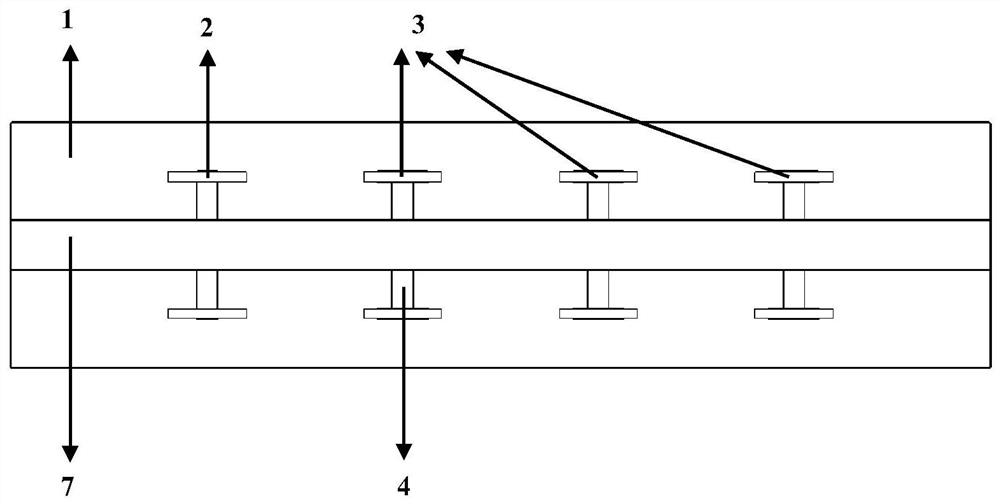

[0027] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the multi-span beam structure of a broadband vibration-reducing and noise-reducing metamaterial includes a base plate 1, a fixed support assembly, a long beam 7, M flexible support assemblies, and M+2 vibrators, where M is a positive integer; The base plate 1 is a cuboid, the fixed support assembly is arranged on one end of the upper surface of the base plate 1, M flexible support assemblies are equidistantly arranged on the upper surface of the base plate 1 along the length direction of the base plate 1, and the fixed support assembly and each flexible support The components are all fixedly connected to the bottom plate 1, M+2 vibrators are equidistantly arranged on the lower surface of the long beam 7 along the length direction of the long beam 7, and each vibrator is fixedly connected to the lower surface of the long beam 7, and the long beam 7 is set On the fixed support component and ...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment. This embodiment is to further limit the fixed support assembly in the specific embodiment. In this embodiment, the fixed support assembly includes a support cylinder A9, a smooth ring A10 and two circular hole support steel plates 2, Two circular hole supporting steel plates 2 are arranged oppositely, and the upper part of the side wall of each circular hole supporting steel plate 2 is provided with a through hole. Through hole interference fit, the smooth ring A10 is set in the middle of the outer surface of the support cylinder A9, and the smooth ring A10 is rotationally connected with the support cylinder A9, and the lower surface of the long beam 7 is bonded to the smooth ring A10. The bottom surface of a circular hole supporting steel plate 2 is affixed to the upper surface of the base plate 1, and the axis of the support column A9 is arranged in parallel with the broads...

specific Embodiment approach 3

[0031] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment. This embodiment is to further limit the flexible support assembly described in the second specific embodiment. In this embodiment, the flexible support assembly includes a support cylinder B4, a smooth ring B8 and two long-hole support steel plates 3. Two long-hole supporting steel plates 3 are arranged opposite to each other. A horizontal strip-shaped hole is provided on the upper part of the side wall of each long-hole supporting steel plate 3. The two ends of the supporting cylinder B4 are respectively arranged in a horizontal strip-shaped hole, and the supporting cylinder Each end of B4 is slidingly connected with a horizontal strip hole, the smooth ring B8 is sleeved in the middle of the outer circular surface of the support cylinder B4, and the smooth ring B8 is rotationally connected with the support cylinder B4, and the lower surface of the long beam 7 is bonded to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com