Tipping paper cutting device

A tipping paper and cutting technology, which can be used in transportation and packaging, sending objects, thin material handling, etc., and can solve problems such as troublesome processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

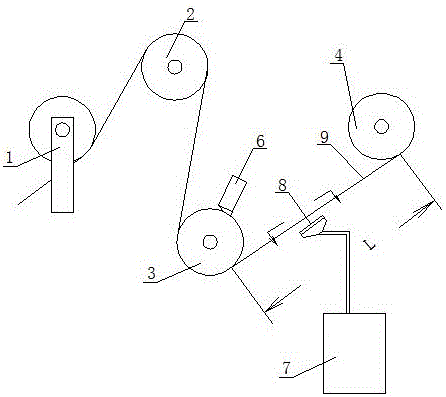

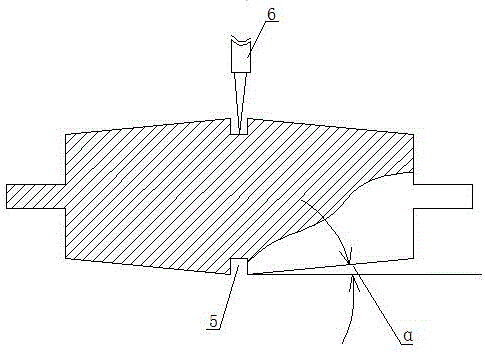

[0021] Such as figure 1 , 2 As shown, a tipping paper cutting device includes a frame 1 on which a plurality of coiling rollers 2 driven by a power device, a cutting roller 3 and a finished product roll 4 are installed. The coiling rollers are used for conveying and connecting The parts of the paper, the finished roll is the part of the coiled and cut tipping paper, the cutting roll has a cutting gap 5, and a cutting knife 6 is installed in front of the cutting roll, and the blade of the cutting knife is inserted into the gap of the cutting roll Among them, it is characterized in that: the cutting roller has a tapered structure from the cutting gap to both sides, and the cutting roller near the cutting gap has the largest diameter.

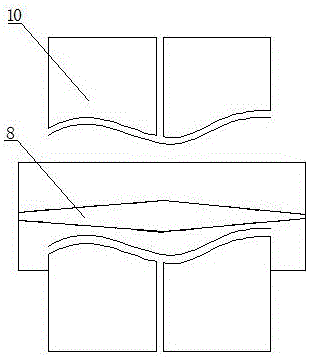

[0022] After the tipping paper is cut, when it is coiled on the finished product roll, there is a distance between them. Because the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com