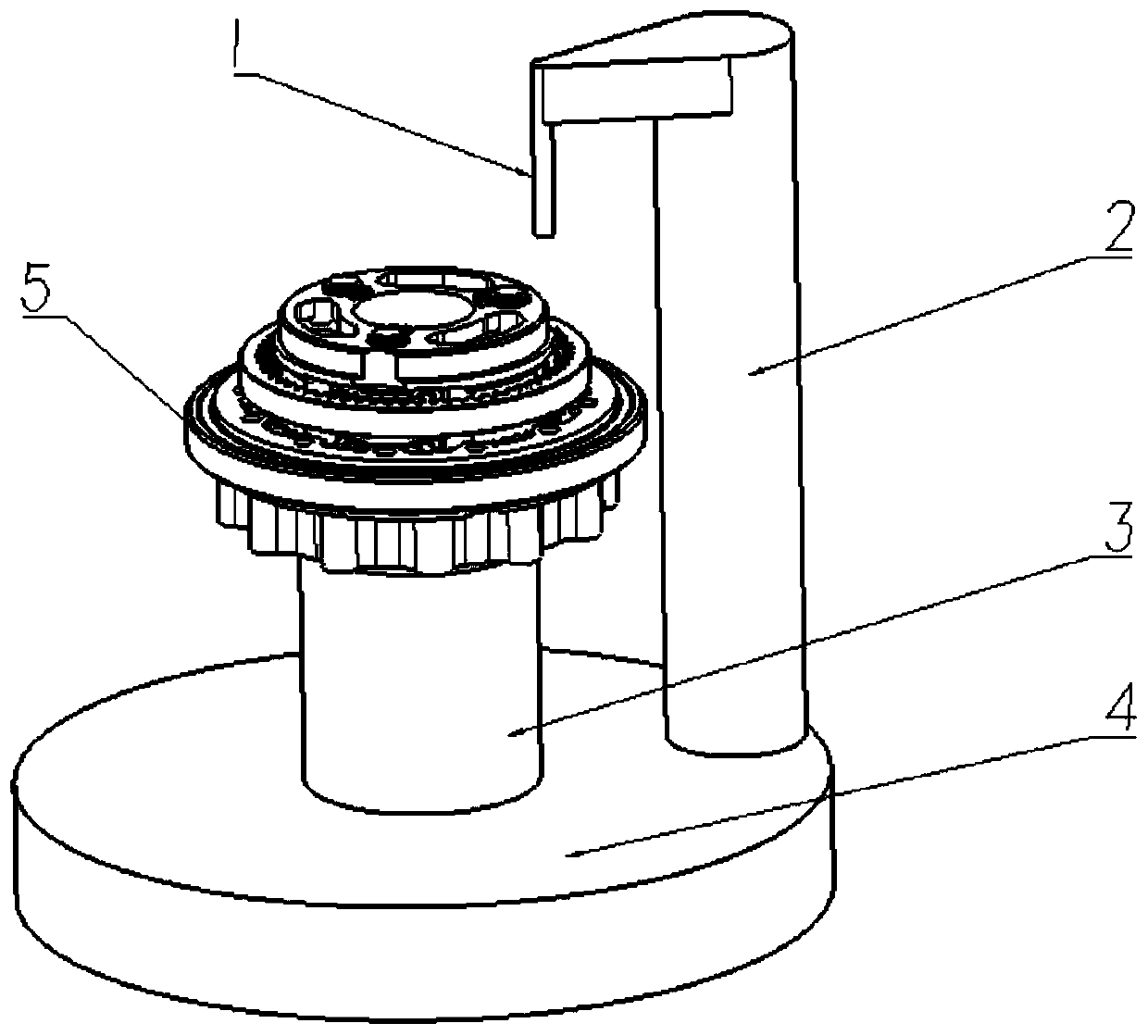

Duplex tooth production device of high-precision speed reducer for robot and application method thereof

A production device, a technology of double gears, applied in the field of machinery, can solve the problems of lack of assembly conditions, reduced performance of the reducer, and inability to meet the use requirements, etc., to ensure machining accuracy, eliminate phase angle errors, and eliminate tooth alignment errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

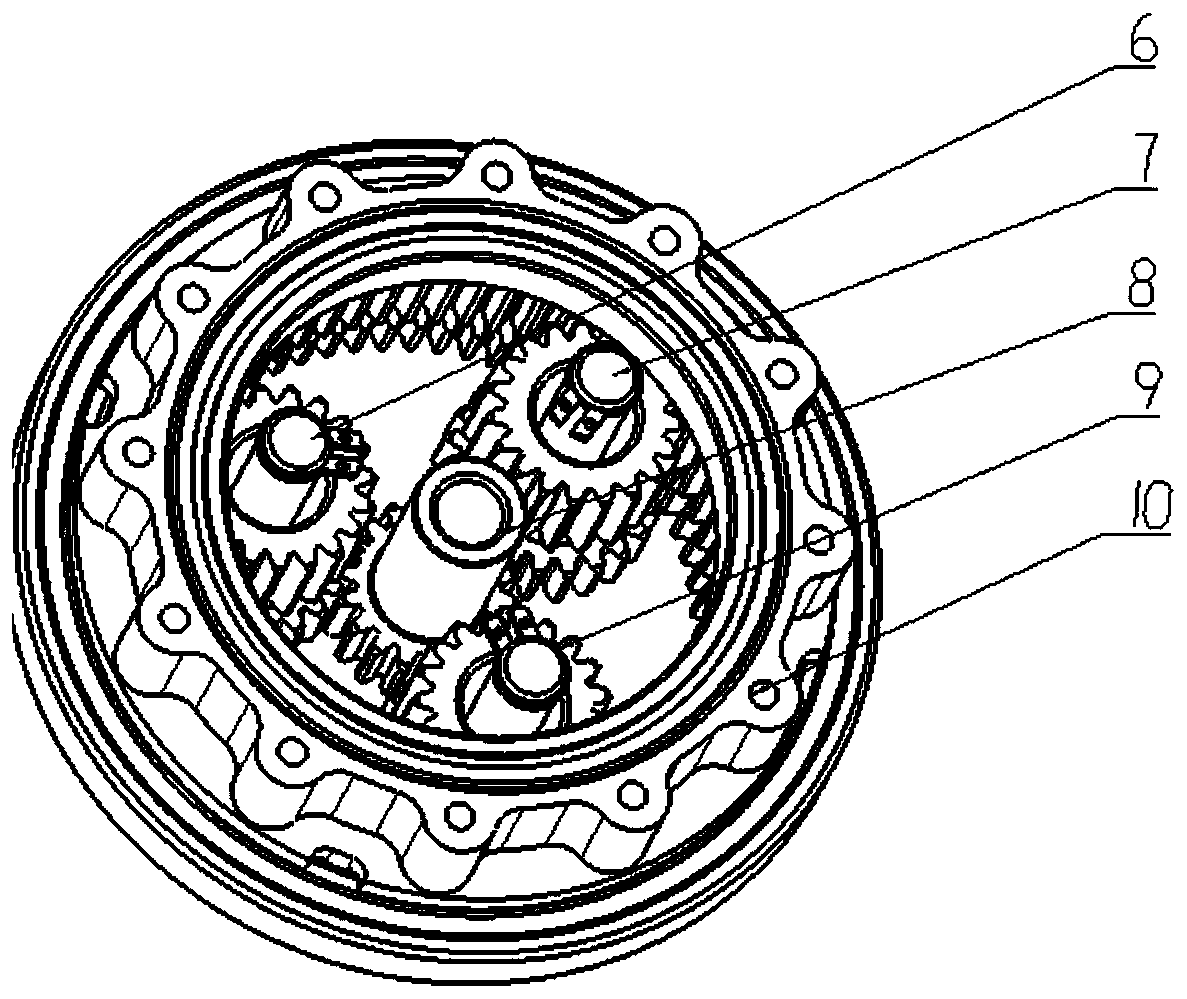

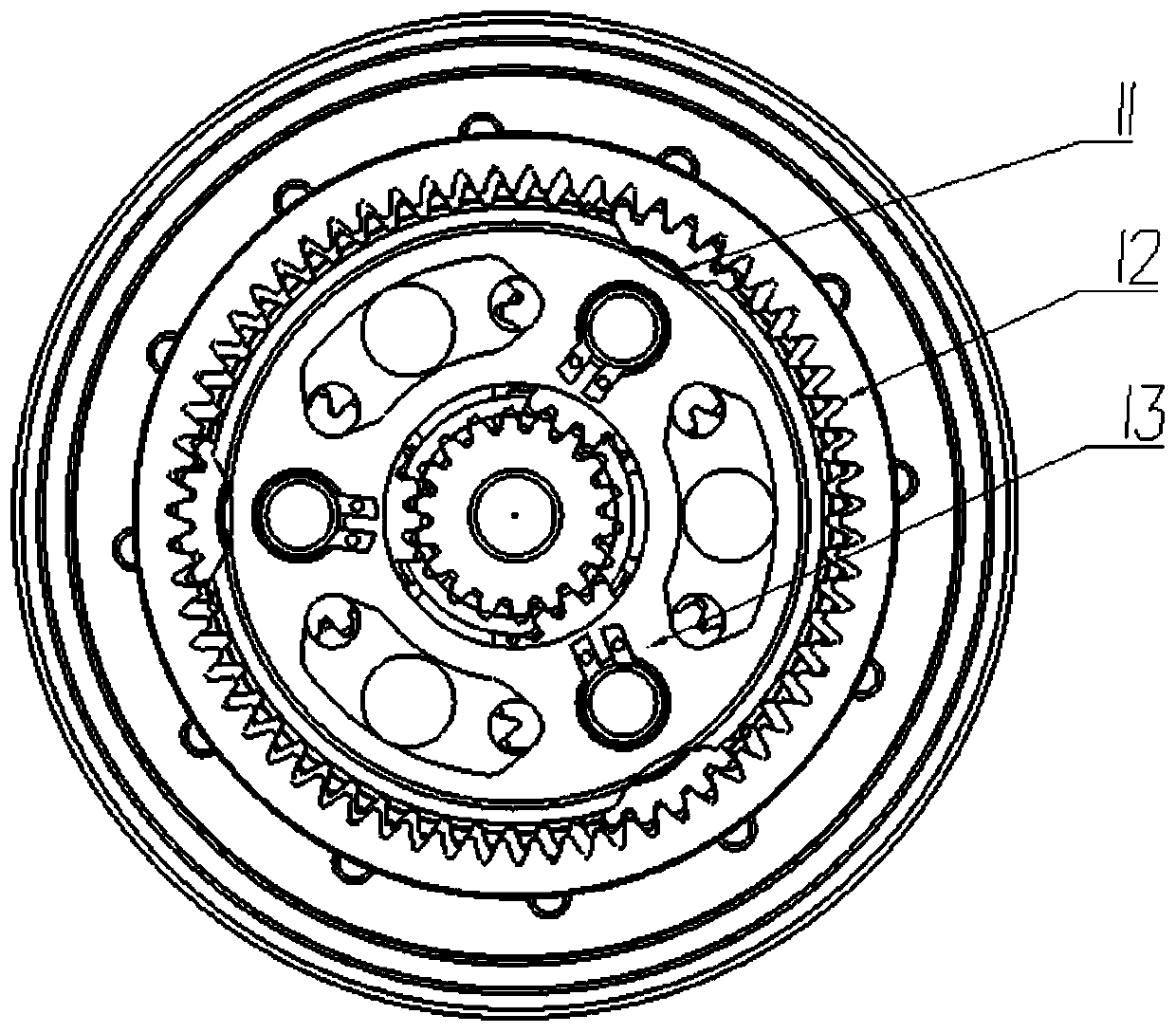

[0036] Embodiment 1: first install the double gear A6, double gear B7 and double gear C9 inside the reducer main body 5, and install the rotating shaft of the central gear 8 of the reducer main body 5 on the slewing mechanism 3, and then install the double gear The rotating shafts of tooth A6, double tooth B7 and double tooth C9 are installed on the turntable 13. When in use, the turntable 13 and the output ring gear 10 are first fixed, and a constant torque is provided through the rotary mechanism 3. This torque needs to be Ensure that the two gears of each set of dual gears can rotate relative to each other, because the two gears of the dual gears are in transition fit with the rotating shaft, and can rotate relative to each other when the torque reaches a certain level. During the rotation, each gear contacts The matching parts are in full contact, and the double gear A6, double gear B7 and double gear C9 evenly distribute the torque of the central gear 8, and the double gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com