Drawer type mold frame

A mold frame and drawer-type technology, which is applied in the field of mold frames, can solve problems such as easy to crush and hurt people's hands and feet, no place to place, high cost, etc., to achieve enhanced support and fixation effects, enhanced fixation effects, and enhanced stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

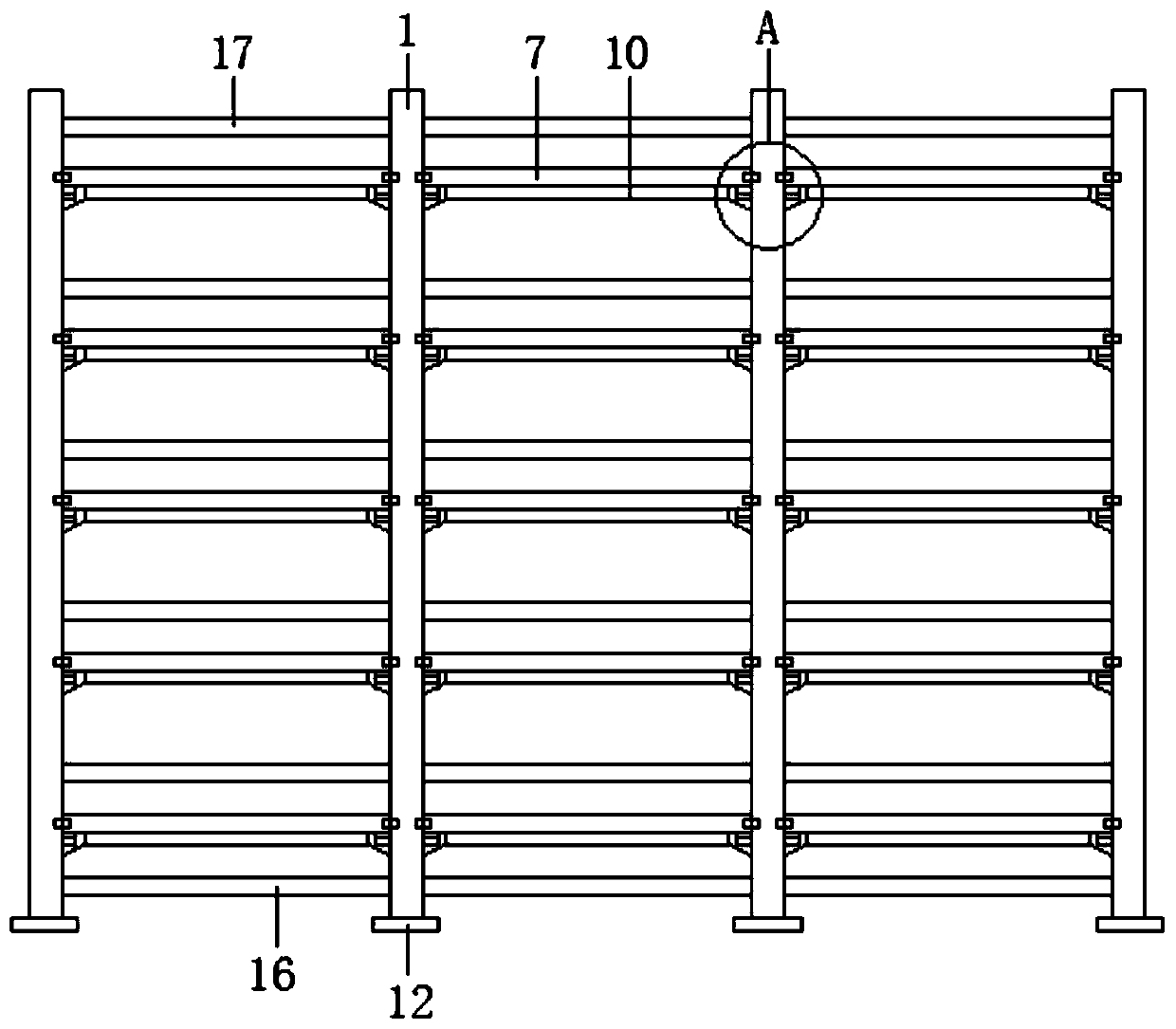

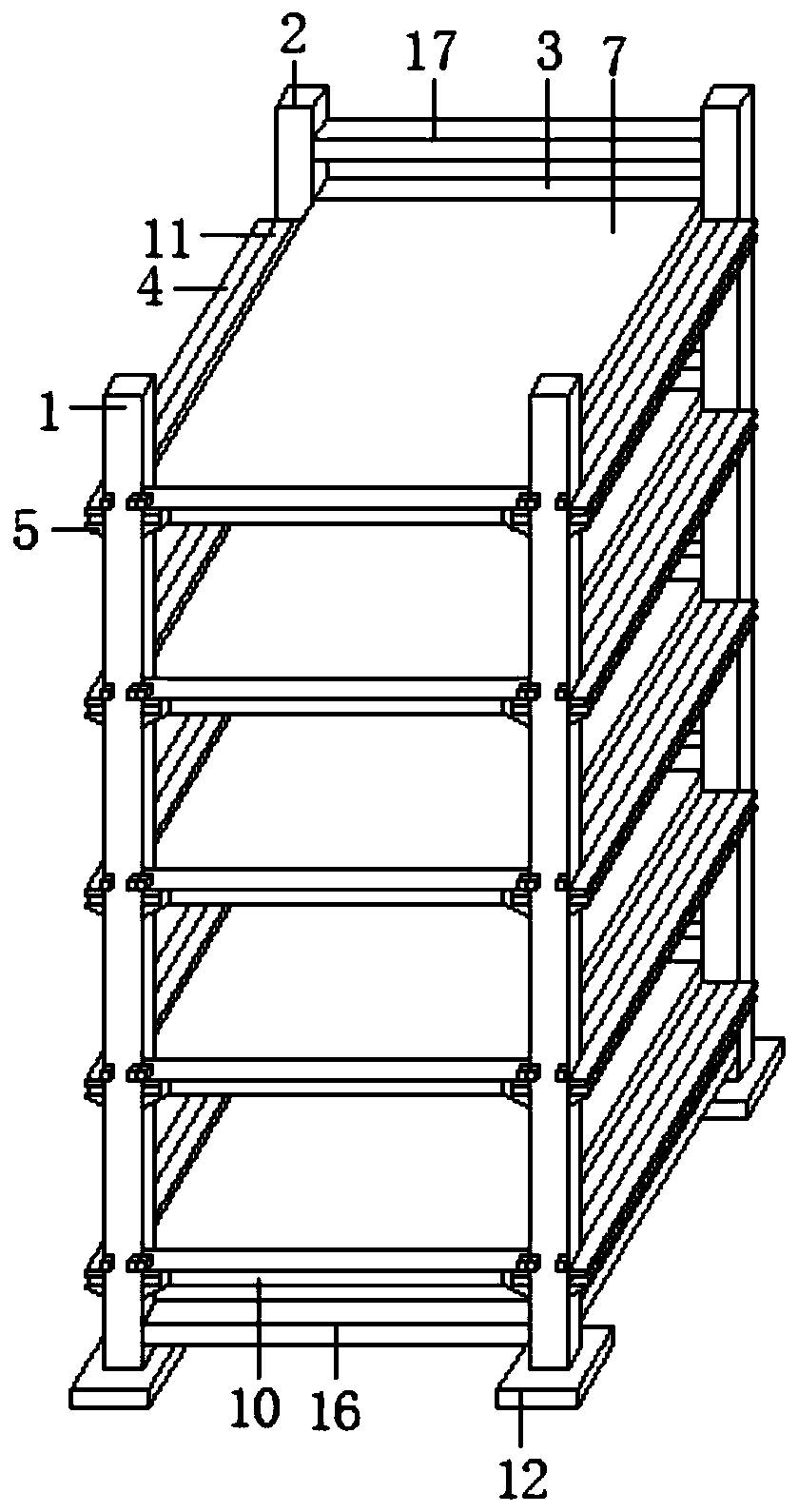

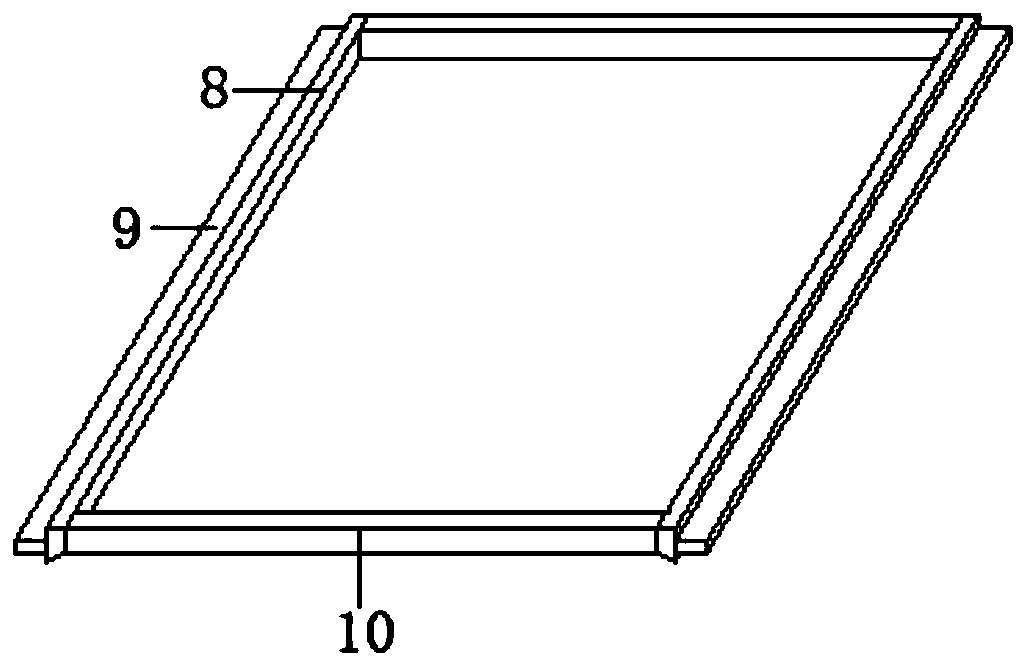

[0024] like Figure 1-5 As shown, a drawer type mold frame includes a first vertical bar 1 and a second vertical bar 2, the first vertical bar 1 is arranged on the front side of the second vertical bar 2, and the second vertical bar 2 is fixed The first fixing plate 3 is connected, which can not only strengthen the fixing effect on the second vertical bar 2, the upper sliding plate 4 and the lower sliding plate 5, but also block the horizontal plate 9 to prevent the horizontal plate 9 from being pushed into the sliding groove 6 too far. The two ends of the front side of the first fixed plate 3 are respectively fixedly connected with an upper sliding plate 4 and a lower sliding plate 5, and a sliding groove 6 is formed between the upper sliding plate 4 and the lower sliding plate 5, and the upper sliding plate The top of the plate 4 is provided with a placement plate 7 for placing the mould. The bottom of the placement plate 7 is fixedly connected with a connecting plate 8, and...

Embodiment 2

[0028] like figure 1 and figure 2 As shown, between the first vertical bar 1 and the second vertical bar 2, between the first vertical bar 1 and the first vertical bar 1, and between the second vertical bar 2 and the second vertical bar 2 are fixedly connected with The first reinforcing rod 16, and the first reinforcing rod 16 is close to the bottom of the first vertical rod 1 and the second vertical rod 2, to strengthen the stability between the first vertical rod 1 and the second vertical rod 2, the first The top of the fixed plate 3 is provided with a corresponding second reinforcing rod 17, and both ends of the second reinforcing rod 17 are fixedly connected with the second vertical rod 2, while strengthening the stability between the second vertical rods 2, Block the mold that is placed on top of plate 7.

[0029] The working principle of the present invention: when it is necessary to pull the placement plate 7 to facilitate the pick-and-place of the mould, operate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com