A sand washing mud dehydration system

A mud and sand washing technology, applied in the direction of water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of reducing the efficiency of mud concentration, environmental pollution, mud breeding microorganisms, etc., to improve dehydration efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

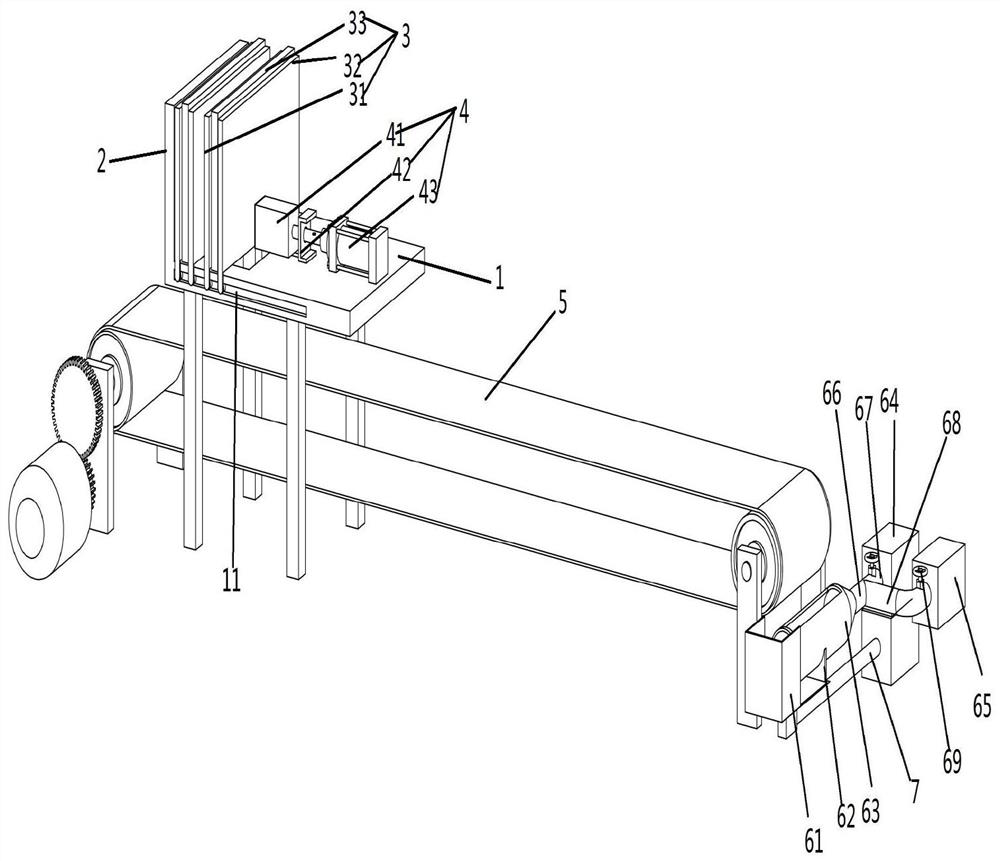

[0030] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

[0031] The vacuum device used in the present invention is a GIS gas vacuum device, and the model is XL-CL;

[0032] The air compressor is a large air compressor, the model is VFD-0.32 / (30-200) -250;

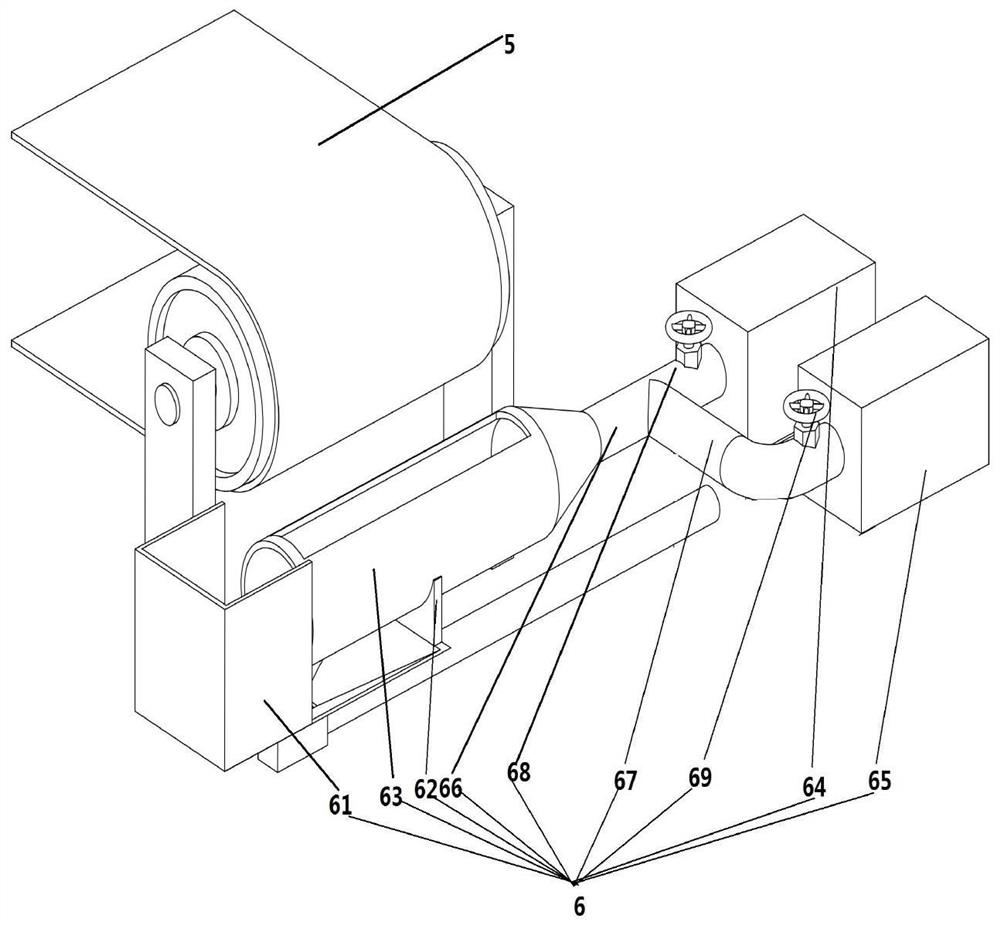

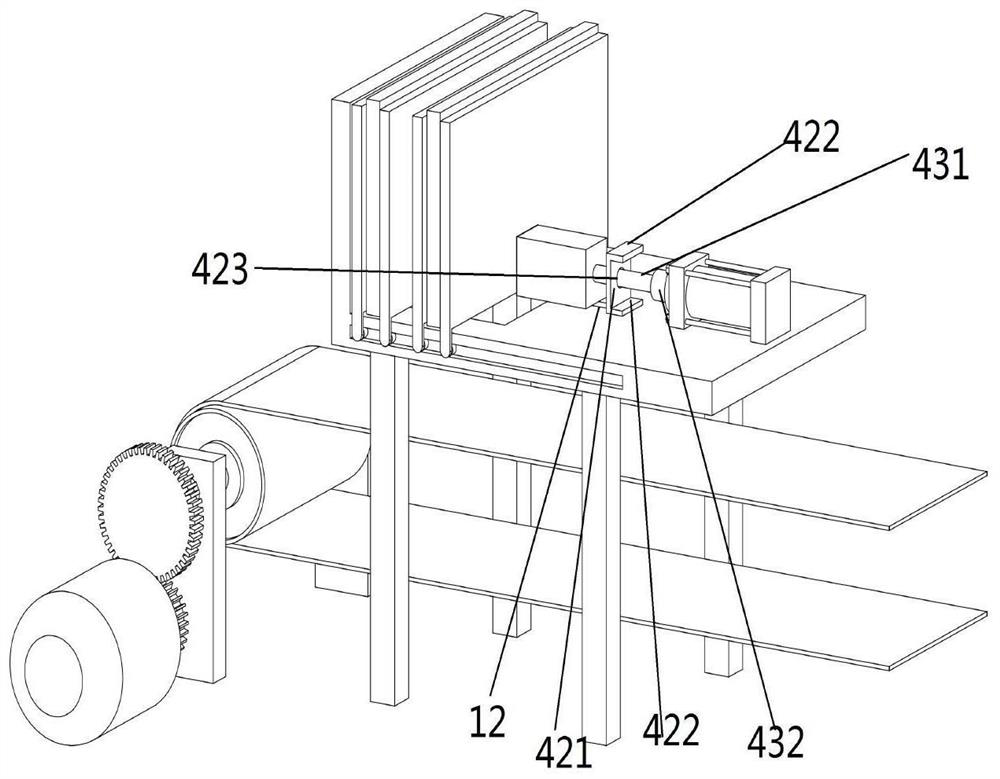

[0033] A sanding mud dewatering system, a frame 1, a thrust plate 2, sequentially disposed, a plurality of filter frames 31 and a plurality of filter plates 32, a slide plate 41, a restricted member 42, a cylinder 43, a sludge discharge cavity 61, The bracket 62 fixed to the slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com