Intelligent sliding sleeve control system and method for downhole multi-stage fracturing based on pressure wave communication

A technology for fracturing sliding sleeves and intelligent sliding sleeves, which is applied in earthwork drilling, wellbore/well components, wellbore/well valve devices, etc., which can solve problems such as complicated operation and cumbersome structure of fracturing sliding sleeves, and achieve Reduced complexity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation of the invention will now be described with reference to the accompanying drawings.

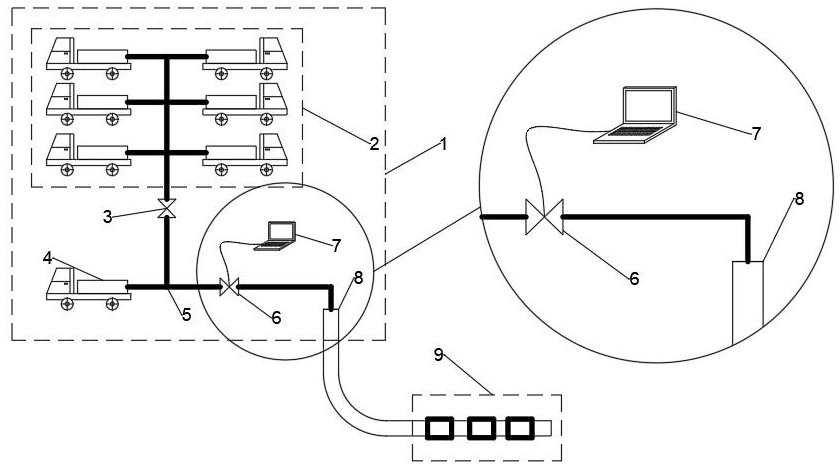

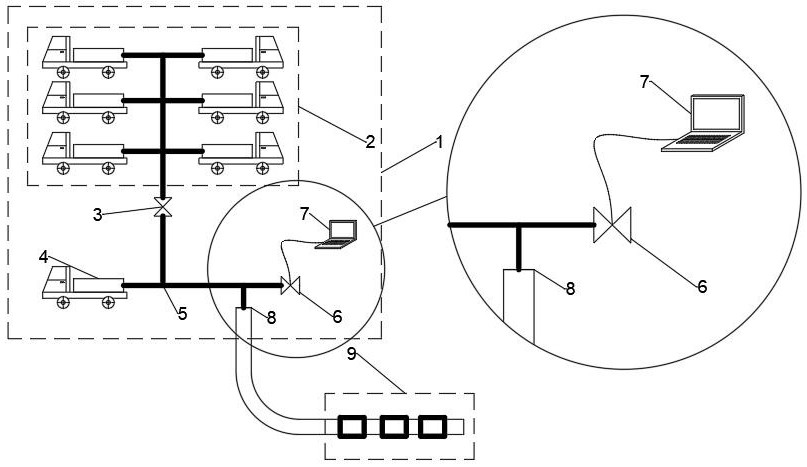

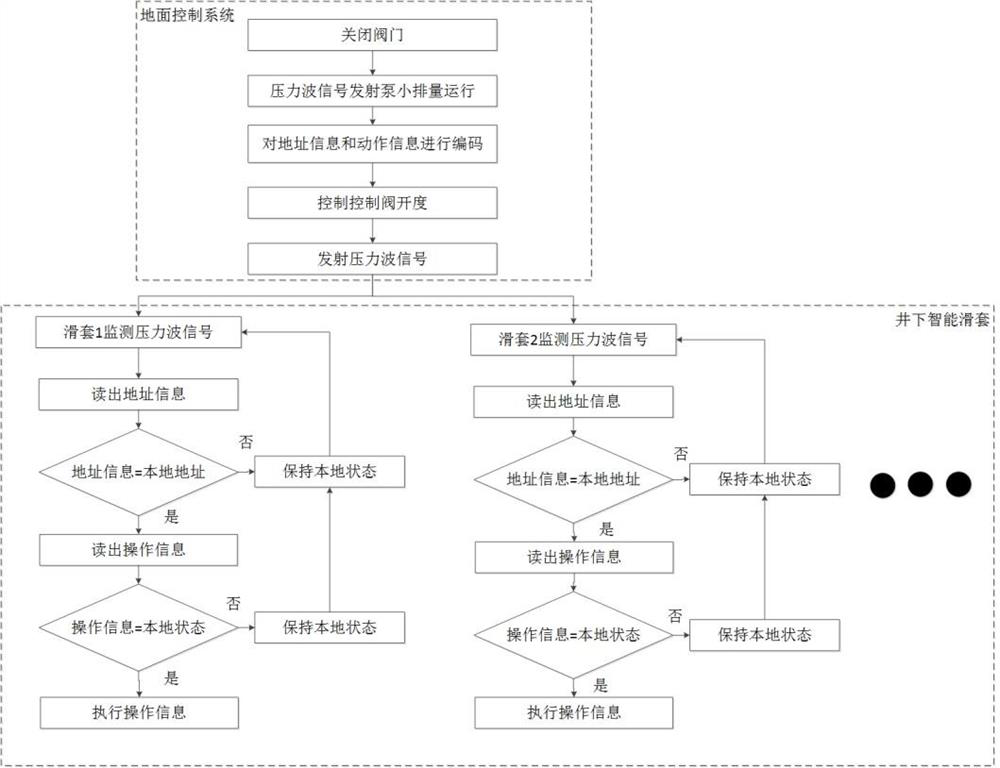

[0027] In this example, if figure 1 and figure 2 As shown, a downhole multi-stage fracturing intelligent sliding sleeve control system and method based on pressure wave communication, the control valve 6 in the ground control device is installed between the pressure wave signal transmitting pump 4 and the wellhead 8 or downstream of the wellhead 8. Before the operation of the split pump group 2, the small displacement operation of the pump 4 is transmitted by the pressure wave signal, and the opening of the pressure relief control valve 6 or the throttling control valve 6 is controlled according to the specified sequence to generate a pressure change in the wellbore and transmit the pressure. Wave.

[0028] According to the construction needs, the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com