Method for predicting friction coefficient of keyless joint surface

A friction coefficient and prediction method technology, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of lack of prediction methods and the inability to accurately specify the friction coefficient of the joint surface of keyless joints, so as to solve the problems that cannot be accurately solved. Given and predicted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

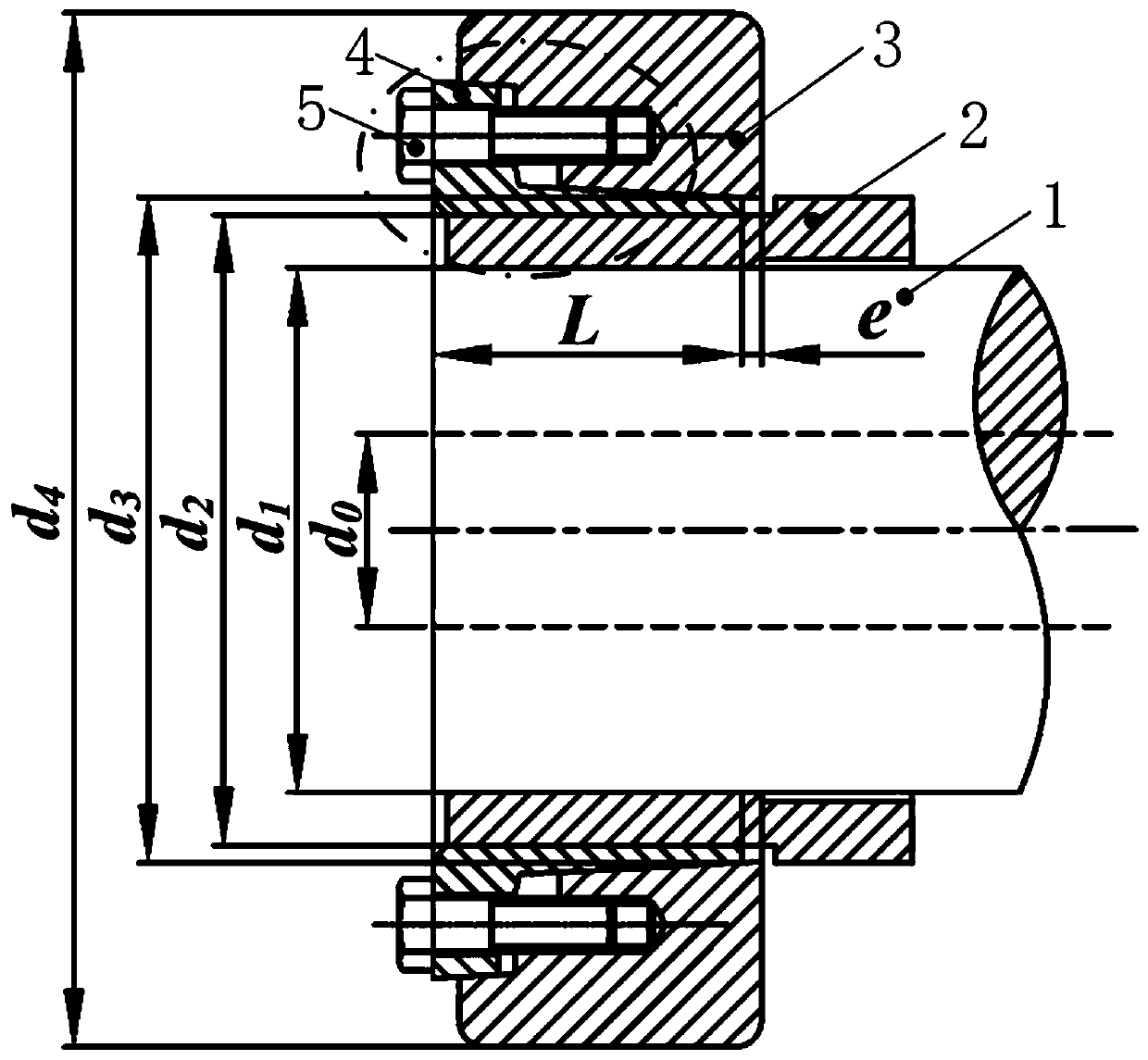

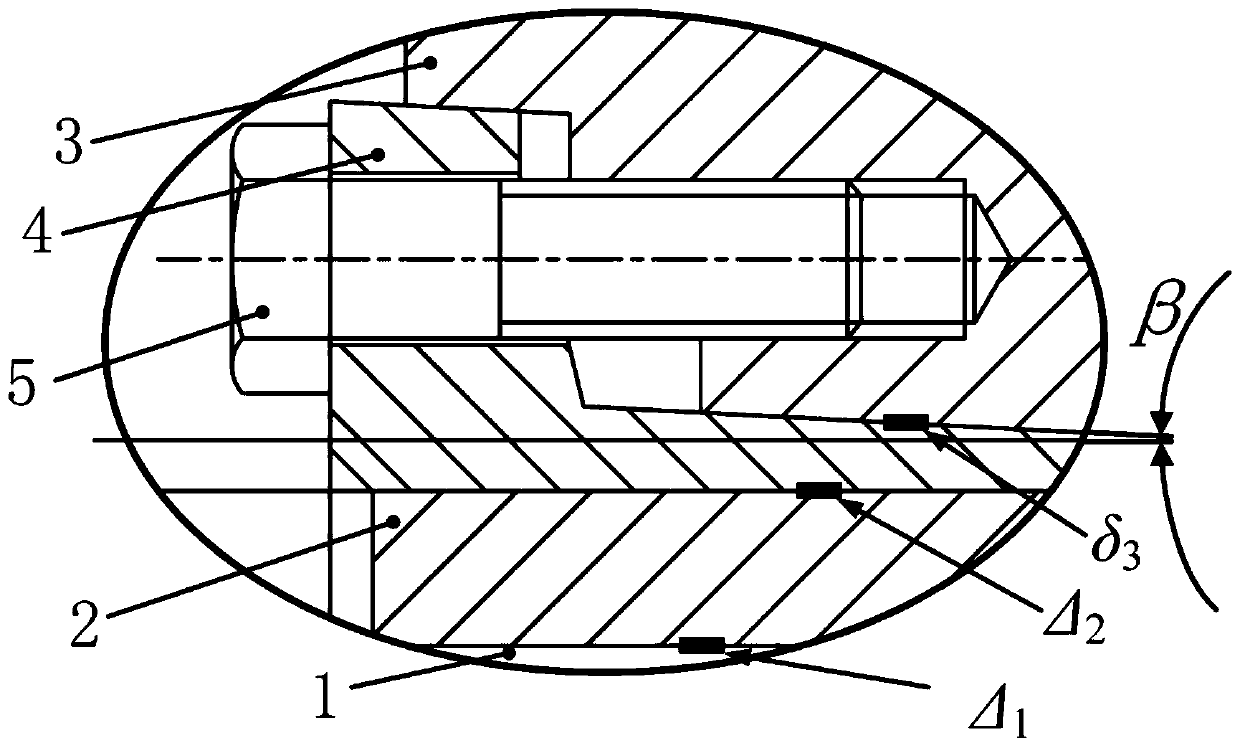

[0028] Such as figure 1 As shown, a method for predicting the friction coefficient of the joint surface of a keyless joint in this embodiment, the keyless joint adopts an expansion joint sleeve composed of an inner ring 4, an outer ring 3 and a bolt 5, and the expansion joint sleeve is set On the shaft sleeve 2 and the main shaft 1, the method for predicting the coefficient of friction of the joint surface produced by the shaft sleeve 2 and the main shaft 1 comprises the following steps:

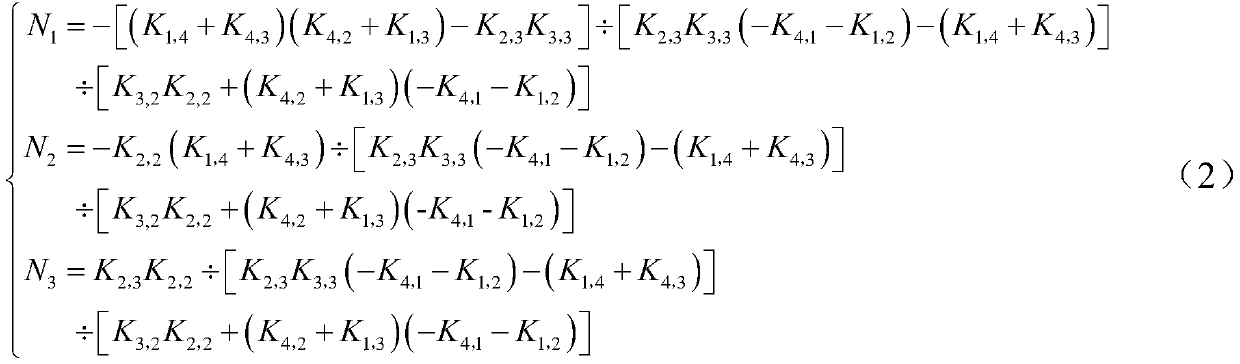

[0029] 1) Calculate the pressure p on the contact surface between the main shaft 1 and the sleeve 2 according to elastic mechanics 1 :

[0030] p 1 =N 1 ·Δ 1 +N 2 ·Δ 2 +N 3 ·δ 3 (1)

[0031] In the formula, Δ 1 is the assembly clearance between the main shaft and the sleeve, Δ 2 is the assembly gap between the sleeve and the inner ring, δ 3 is the interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com