A control method of a speed servo system

A servo system and control method technology, applied in the direction of motor parameter estimation/correction, etc., can solve the problems of slow adjustment speed and large dynamic error, achieve the requirements of reducing resolution, improve dynamic performance, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the orientation terms such as left, middle, right, up, and down in the examples of the present invention are only relative concepts or refer to the normal use state of the product, and should not be considered as restrictive .

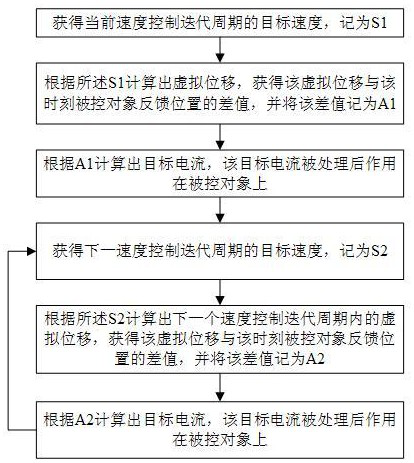

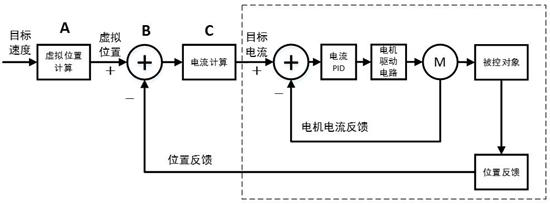

[0018] A control method for a speed servo system, such as figure 1 shown, including the following steps:

[0019] Step 1: Obtain the target speed of the current speed control iteration cycle, denoted as S1;

[0020] Step 2: Calculate the virtual displacement in the current speed control iteration cycle according to the S1, obtain the difference between the virtual displacement and the feedback position of the controlled object at this moment, and record the difference as A1;

[0021] Step 3: Calculate the target current according to A1. After subtracting the motor feedback current from the target current, the PID oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com