Manufacturing method of waterproof connector and waterproof connector

A waterproof connector and the technology of the manufacturing method are applied in the parts of the connection device, dustproof/splashproof/leakproof/waterproof/fireproof connection, connection, etc., which can solve the problems affecting the lighting effect and lighting safety, and achieve Avoid poor contact, improve waterproof effect, and improve the effect of using safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

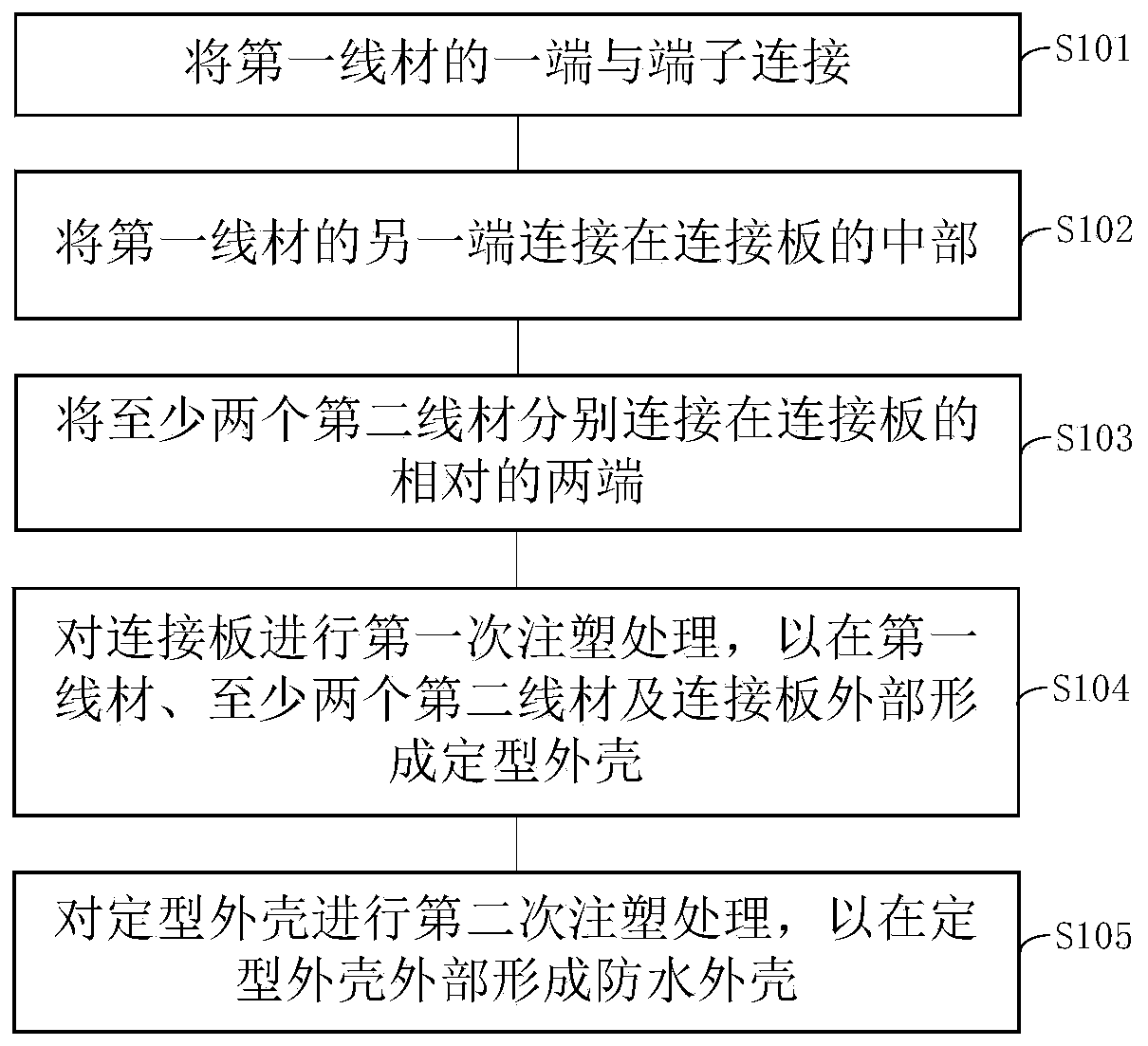

[0056] figure 1 A schematic flow chart of a method for manufacturing a waterproof connector provided by an embodiment of the present invention, as shown in figure 1 shown.

[0057] An embodiment of the present invention provides a method for manufacturing a waterproof connector, including:

[0058] Step S101: Connect one end of the first wire to the terminal;

[0059] The quick connection between the first wire and the external wire can be realized through the terminal, and the connection between the first wire and the terminal includes, but is not limited to, a pressing method.

[0060] Step S102: Connect the other end of the first wire to the middle of the connecting plate;

[0061] The length of the electrical communication path between the first wire and the two ends of the connecting board can be made the same, thereby reducing the difference in electrical transmission between the two ends of the connecting board. The other end of the first wire includes but is not lim...

Embodiment 2

[0080] Based on the manufacturing method of the waterproof connector in the first embodiment, the embodiment of the present invention proposes the second embodiment. In the second embodiment, a waterproof connector is provided accordingly. The waterproof connector can be manufactured according to the manufacturing method of the waterproof connector in Embodiment 1. The specific plan is as follows:

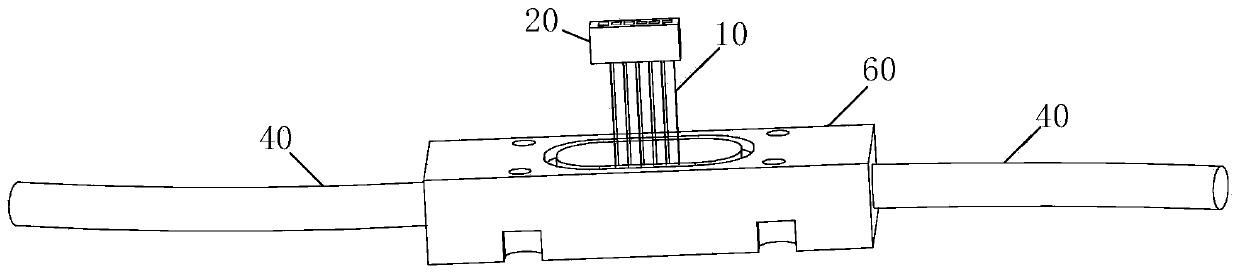

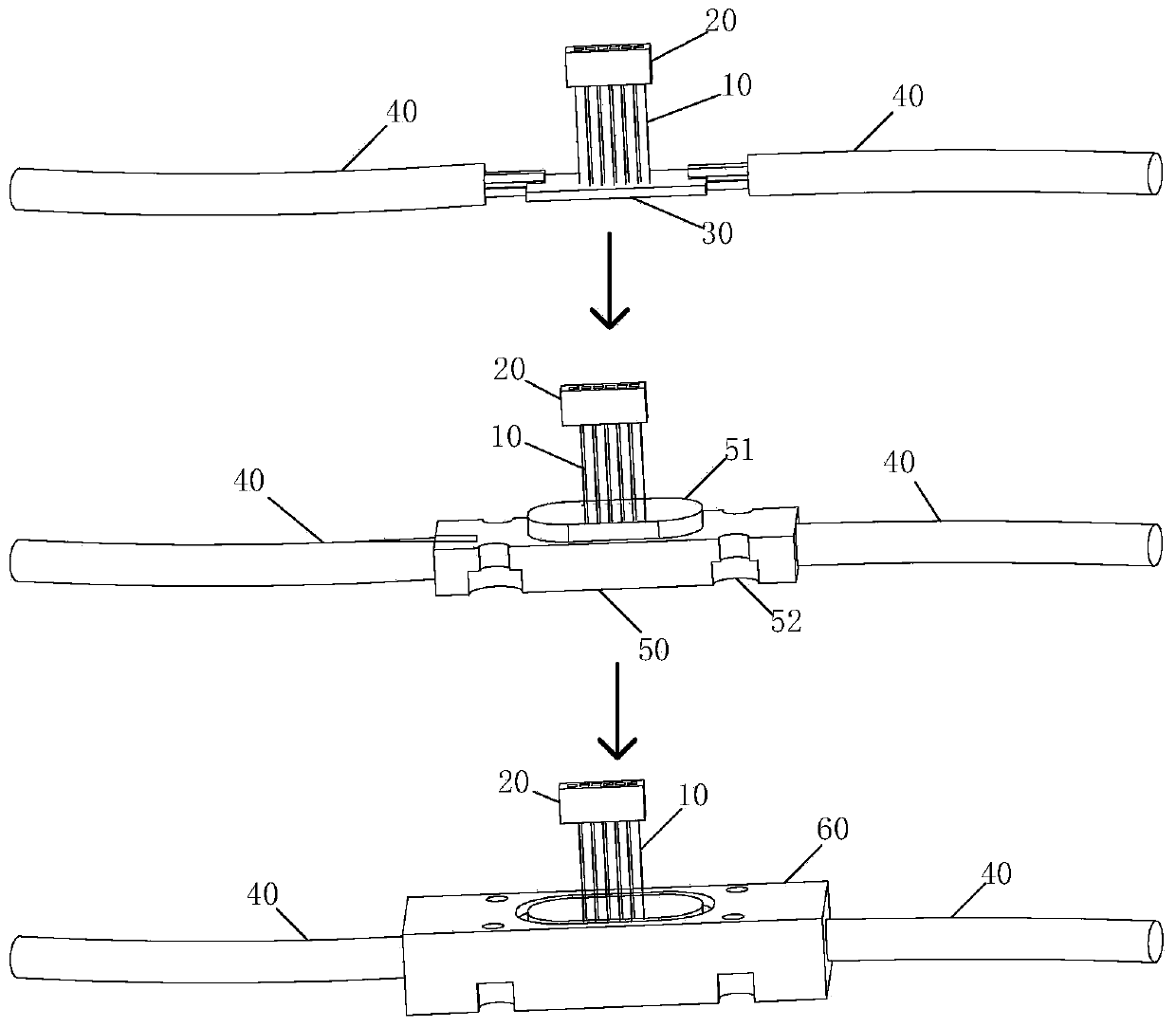

[0081] see figure 2 and image 3 ,in, figure 2 A schematic structural diagram of a waterproof connector provided by an embodiment of the present invention, image 3 It is a schematic diagram of the manufacturing process of the waterproof connector provided by the embodiment of the present invention.

[0082] An embodiment of the present invention provides a waterproof connector, including a terminal 20 , a first wire 10 , at least two second wires 40 and a connecting plate 30 .

[0083] Wherein, one end of the first wire 10 is connected to the terminal 20 , and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com