Multifunctional soft finger realizing stiffness changing through line driving

A variable stiffness and multi-functional technology, applied in the field of multi-functional soft fingers, can solve the problems of limited application scenarios, insufficient grasping force, inaccurate control, etc., and achieve the effects of reliable grasping, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

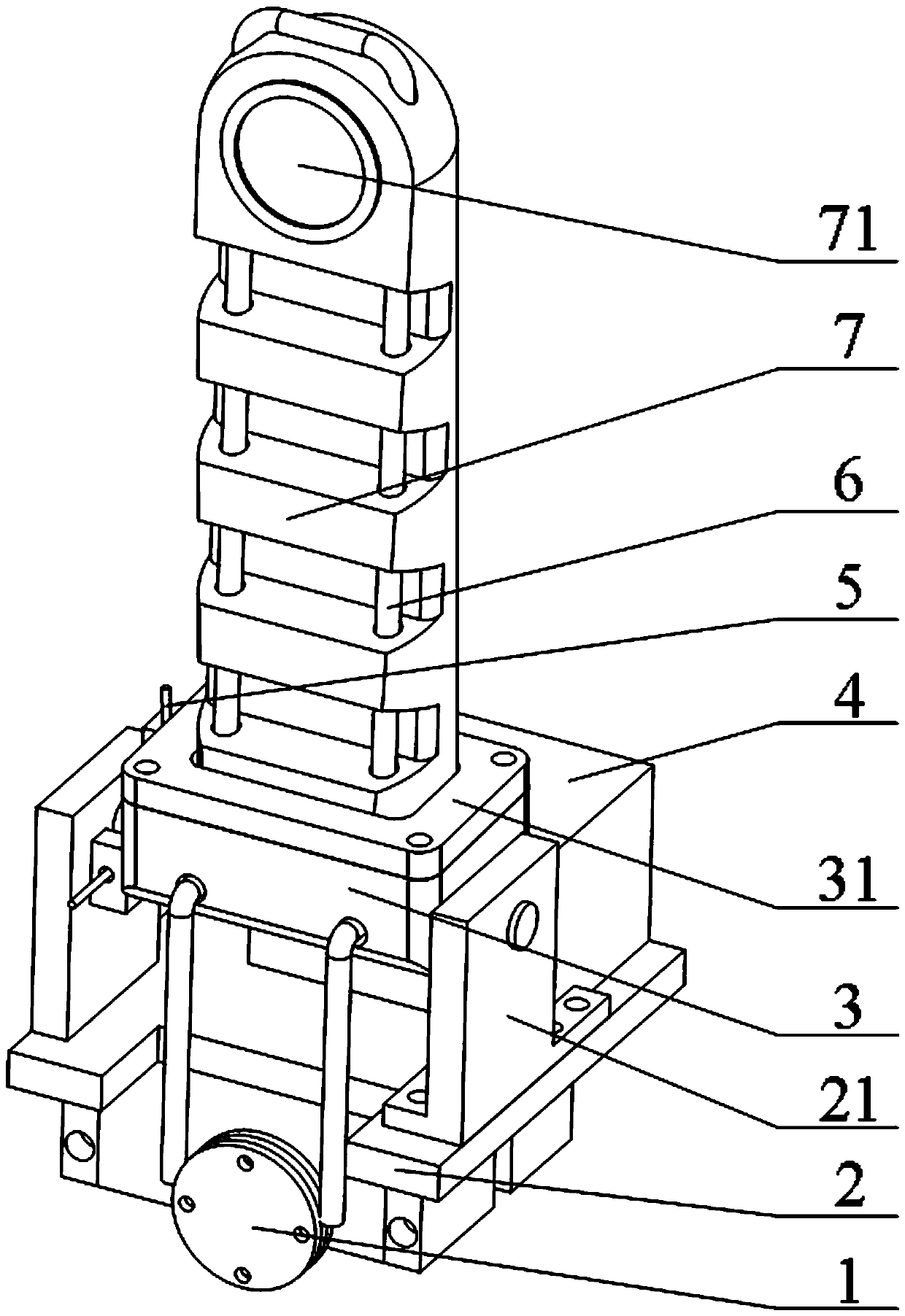

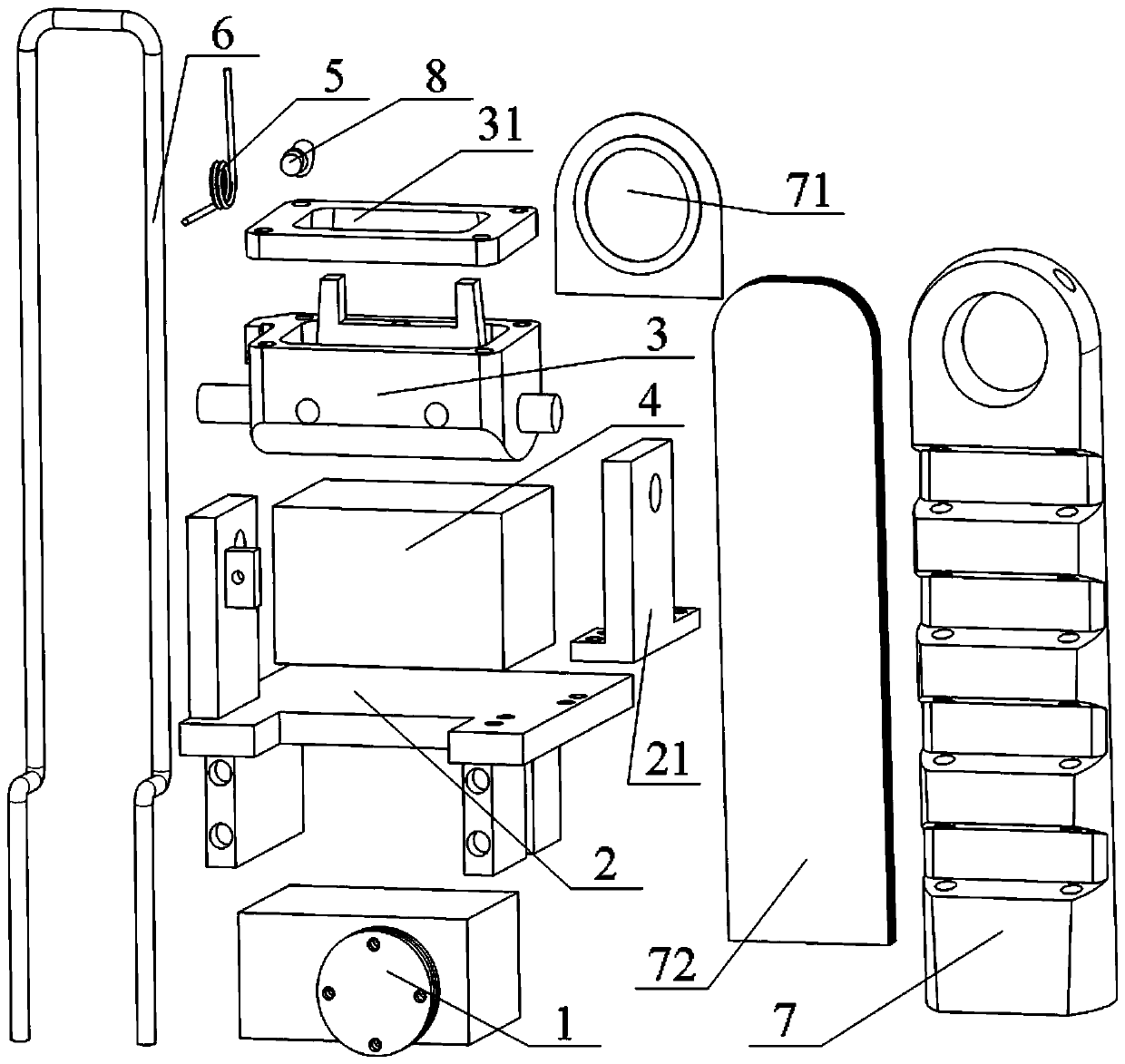

[0025] Such as figure 1 with 2 As shown, a multifunctional soft finger with linear drive stiffness, including base 2, clamp 3, motor 1, negative pressure device 4, torsion spring 5, air duct 8, tendon rope 6 and soft finger 7; soft finger 7 A slope with a certain slope along the length direction is mainly set to enhance the rigidity of the fingertips, and there are 4 grooves on this slope to provide deformation space for the soft finger 7 to bend and improve the grip during grasping. To take the effect, the finger has a containing cavity opened along the length of the finger and a suction cup 71 connected to it. The containing cavity is equipped with a rigidity adjustment medium 72. The lower end of the medium 72 is assembled with the clamp 3 and then filled with silicone rubber to form a sealed containing cavity. A clamp cover 31 is installed on the top opening of the clamp cover 31. The clamp cover 31 is provided with a reserved opening adapted to the root of the soft finger 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com