Conveying mechanism for ceramic substrate

A technology of conveying mechanism and ceramic substrate, applied in the direction of conveyor objects, transportation and packaging, stone processing tools, etc., can solve the problems of complex equipment and low efficiency, and achieve the effect of simple equipment, time saving and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

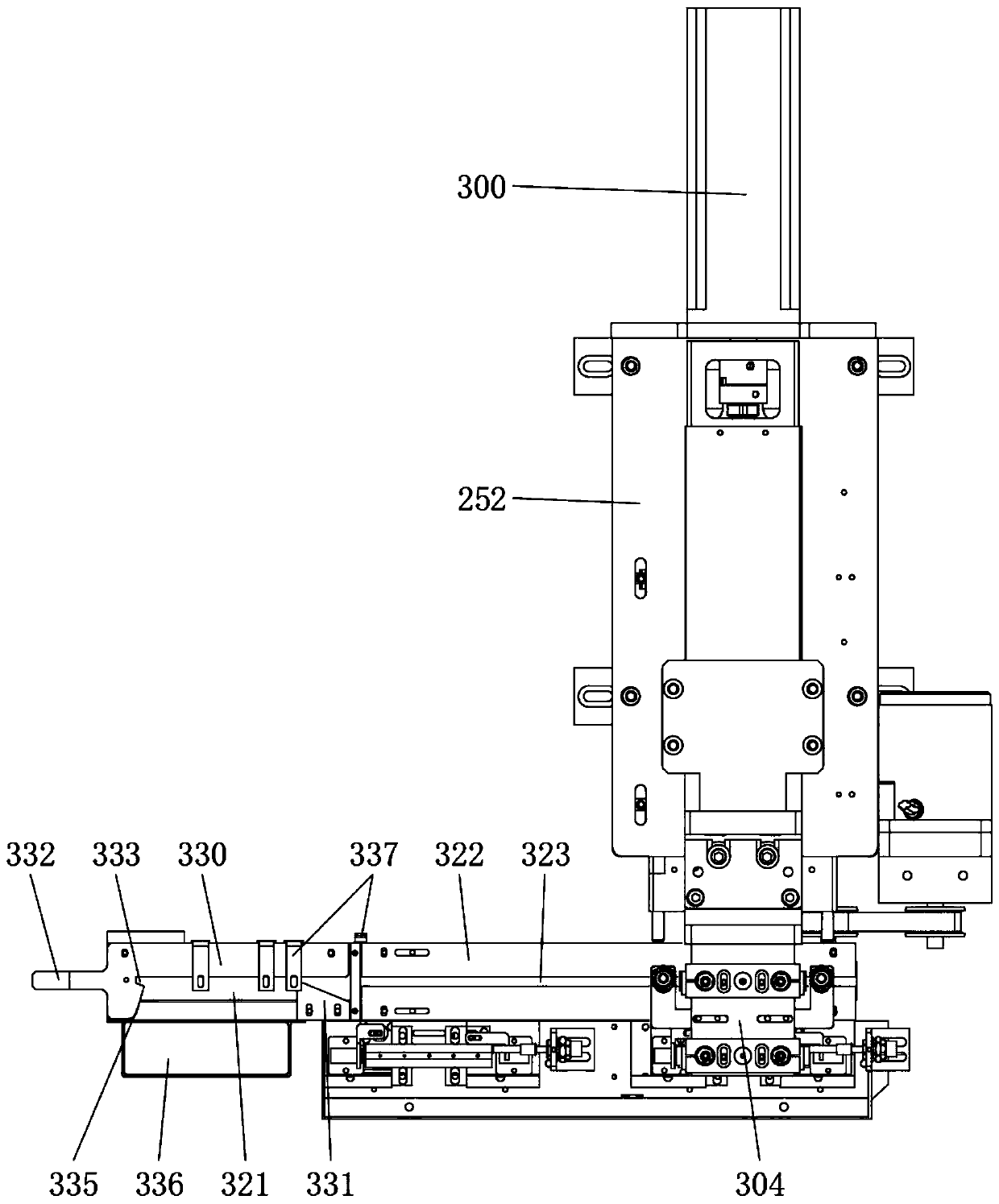

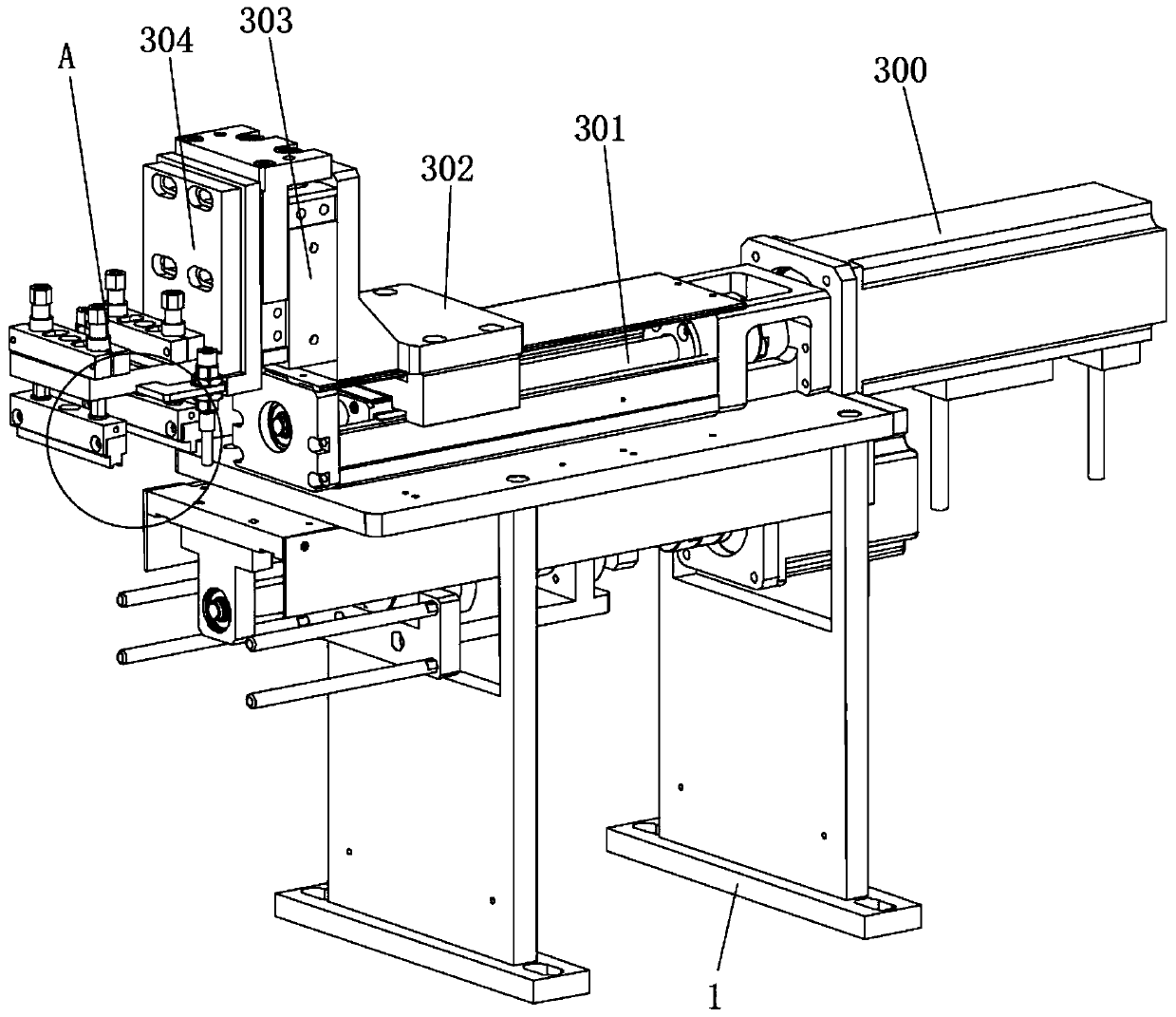

[0026] refer to Figure 1 ~ Figure 4 As shown, the present invention discloses a ceramic substrate conveying mechanism, which includes a base 1, a feeding unit, a feeding head unit, a conveying unit and a guiding and screening unit.

[0027] Feeding unit:

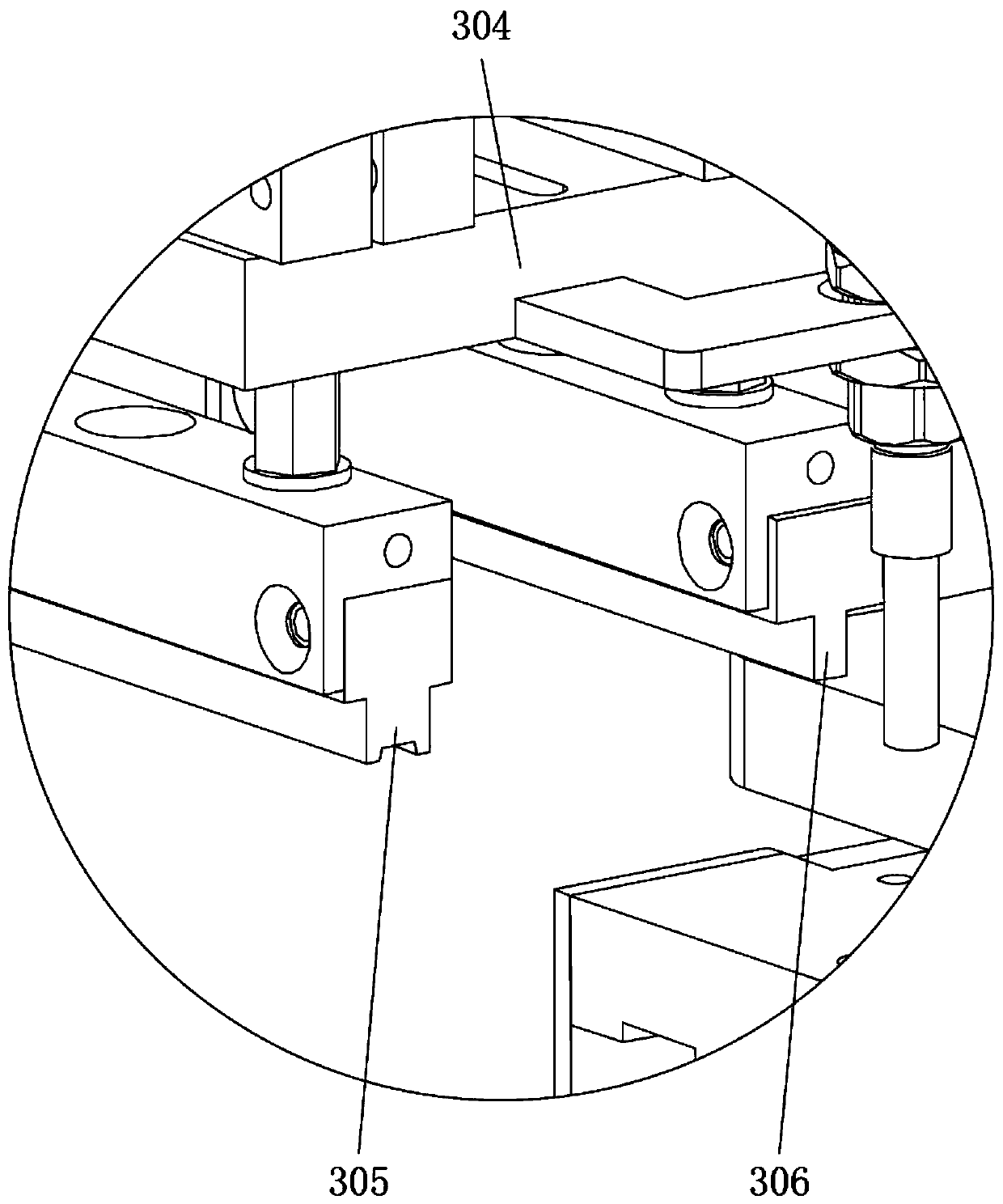

[0028] The above-mentioned loading unit includes an ejection bracket 252 , an adsorption strip 1 305 and an adsorption strip 2 306 having at least two degrees of freedom in the horizontal direction and the vertical direction. The exit bracket 252 is arranged on the base 1 . The first suction strip 305 and the second suction strip 306 are arranged on the withdrawal bracket 252 in sequence along the horizontal direction and the vertical direction. The bottom of the adsorption strip 305 is provided with an inverted "V"-shaped notch. Both the notch and the bottom of the second adsorption strip 306 are provided with air holes. The first adsorption strip 305 can move the ceramic base strip to the beating head platform 310. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com