Automatic mechanical lifting tool

A spreader and machinery technology, applied in the field of automated mechanical spreaders, can solve problems such as poor stability and weak grasping, and achieve the effects of improving stability, reducing workload, and protecting internal structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

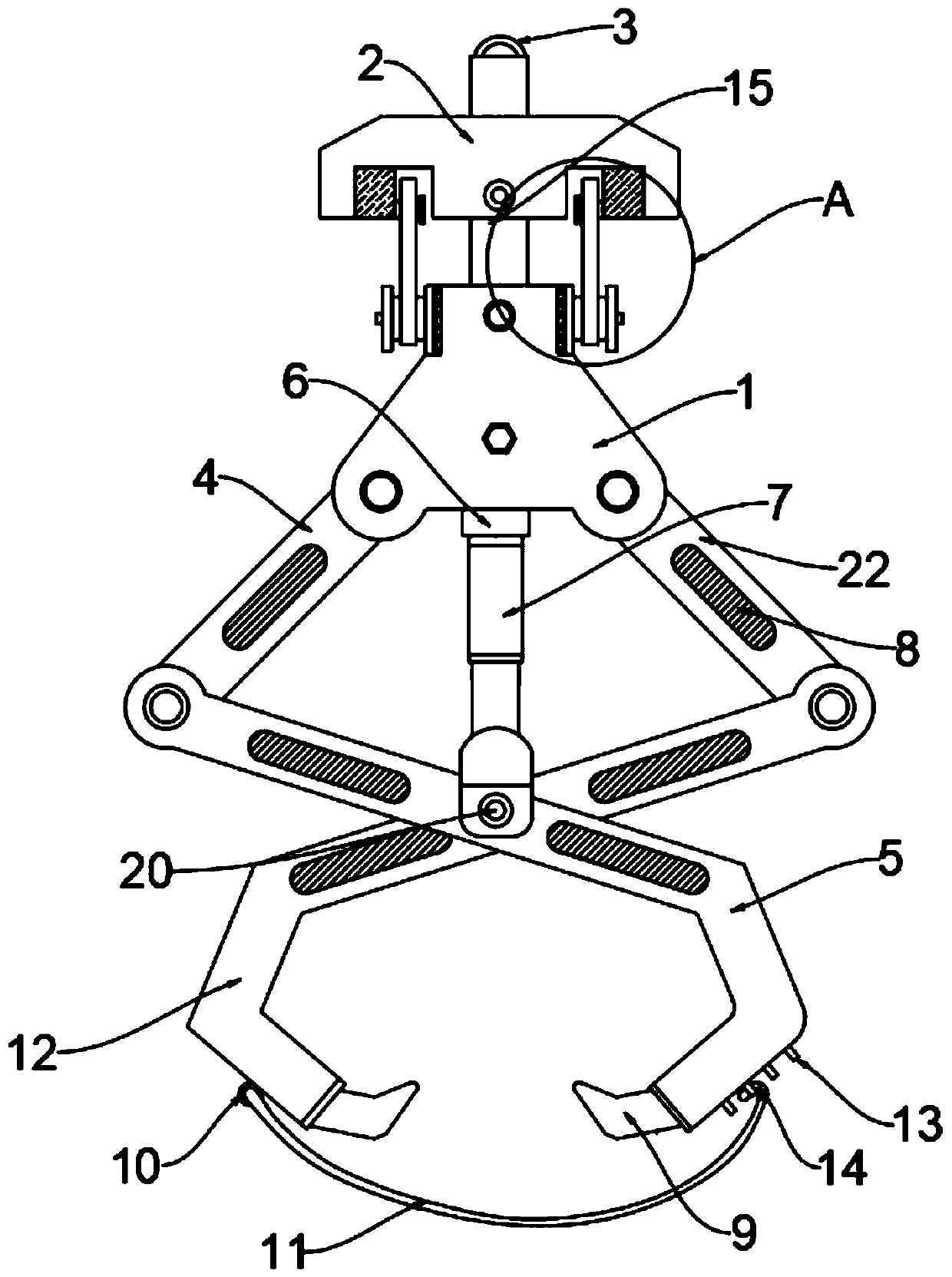

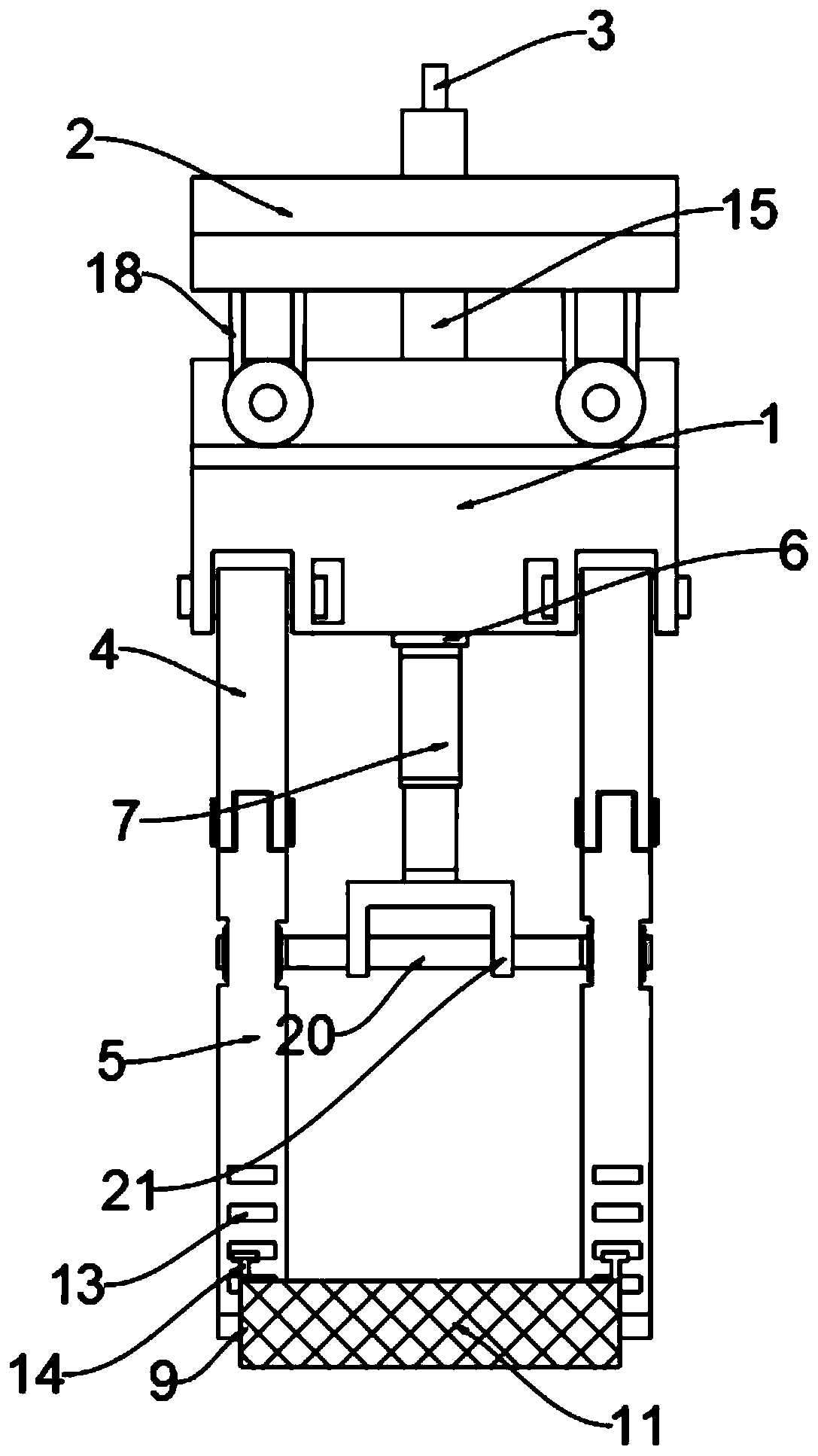

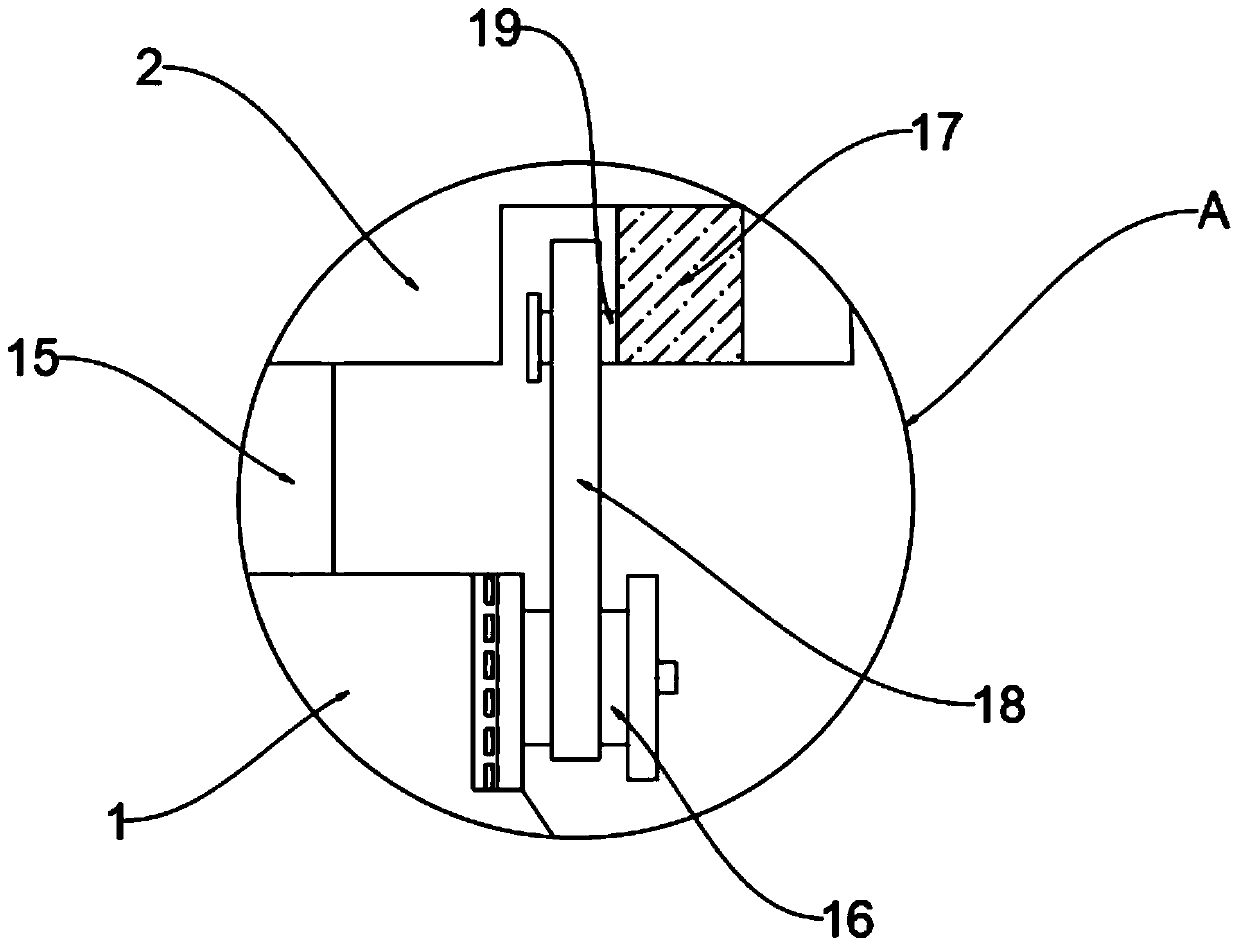

[0020] see Figure 1-3 , an embodiment provided by the present invention: an automatic mechanical spreader, including a spreader frame 1, the interior of the spreader frame 1 is respectively provided with a first oblique arm 4 and a second oblique arm 22, and the first oblique arm 4 Located on one side of the second oblique arm 22, the first tong arm 5 is installed below the first oblique arm 4, the side of the lower end of the first tong arm 5 is provided with a hook ring 13, and the second oblique arm 22 is installed below the second oblique arm. Two pincer arms 12, a net bag 11 is installed between the fixed ring 10 and the hook ring 13, the inside of the fixed ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com