Edge loosening preventive auto-discharging textile edge cutting device

A blanking and trimming technology, which is applied in the cutting of textile materials, textiles and papermaking, metal processing, etc., can solve the problems of increasing the maintenance cost of cutting machinery, retention, and the impact of trimming machinery, etc., and achieves the effect of automatic storage of cutting waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

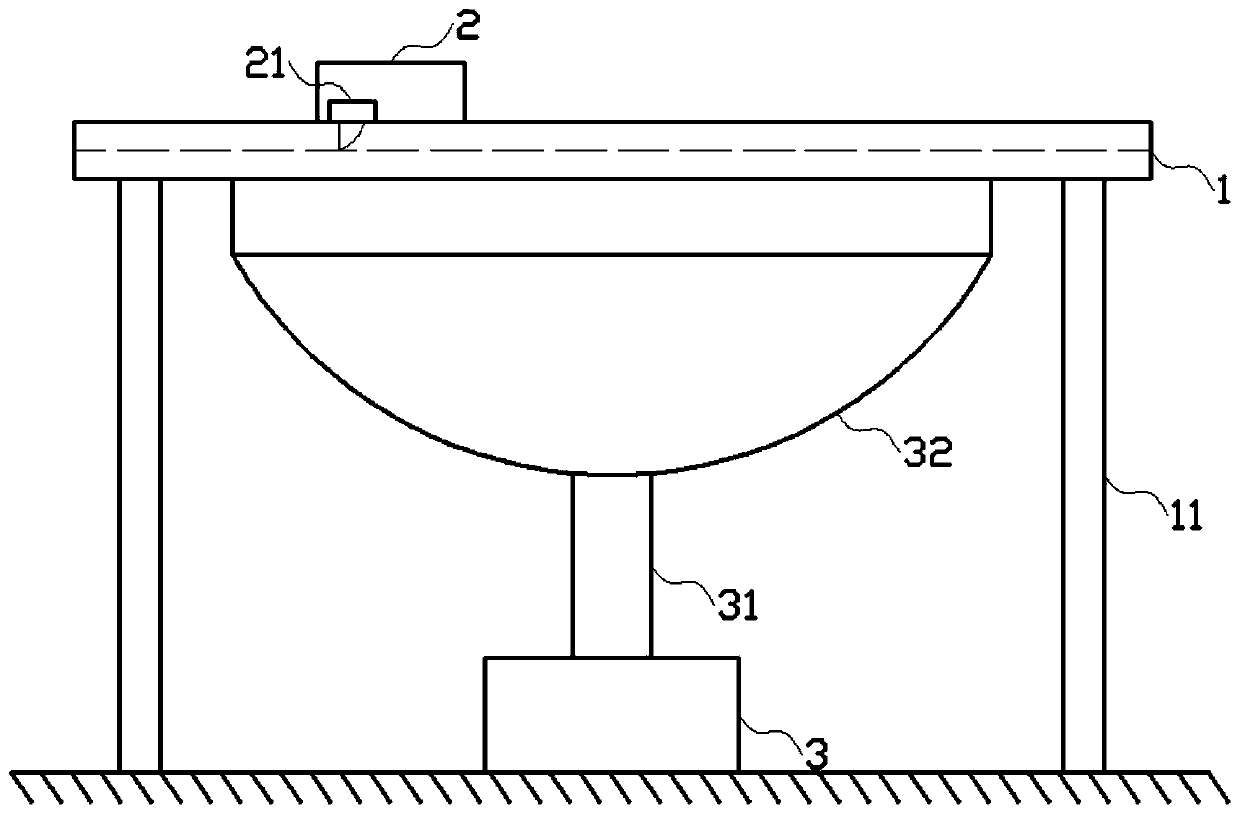

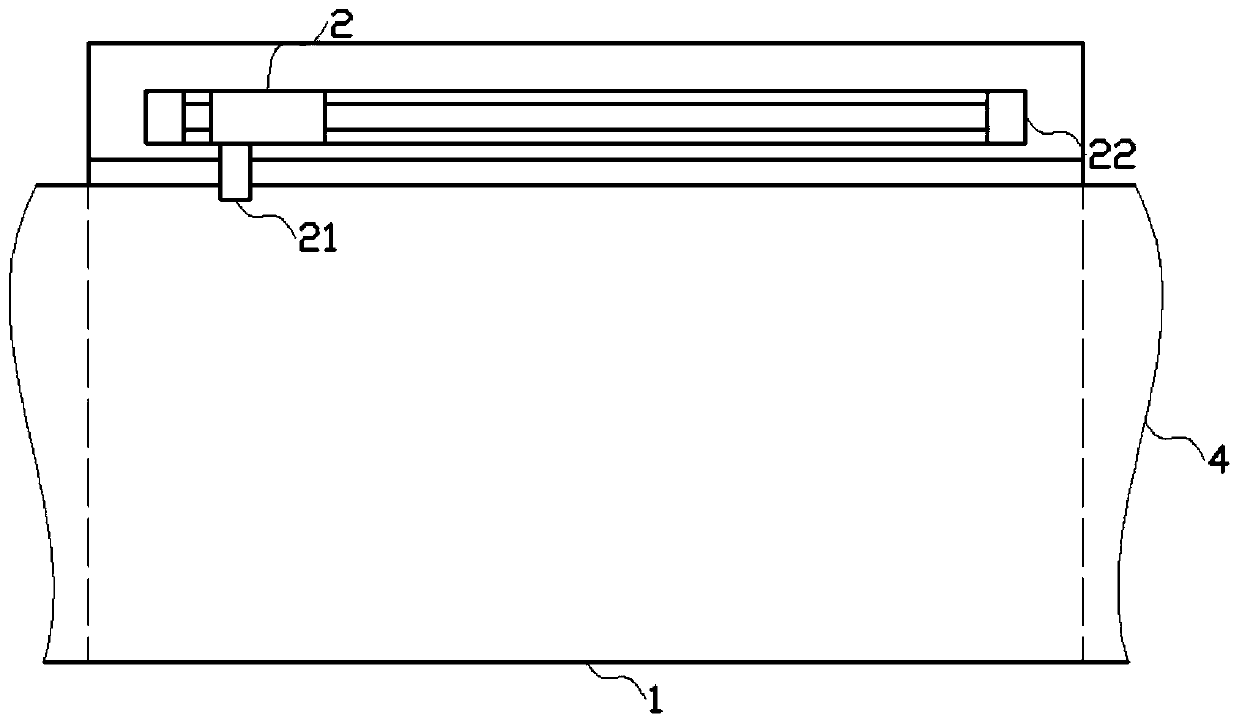

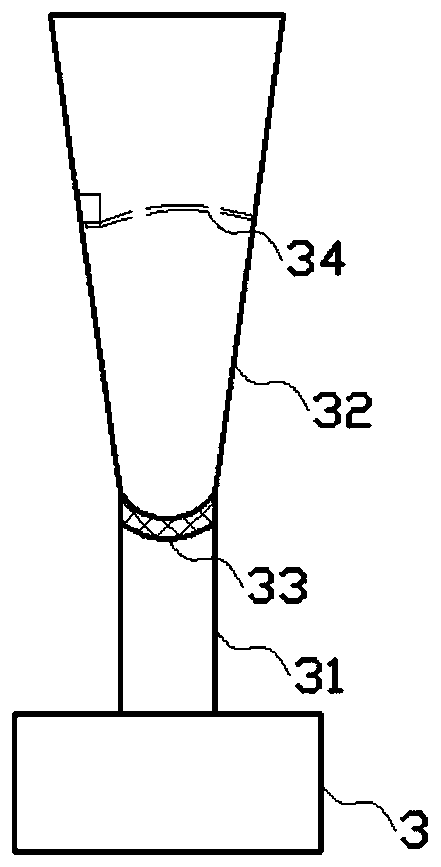

[0013] Such as figure 1 , figure 2 , image 3 As shown in the embodiment, the anti-scattering automatic blanking textile edge trimming device is a kind of operation that automatically pushes the cutting knife through air pressure, which greatly improves the edge trimming efficiency of textile fabrics. The redundant textile fabrics are automatically stored and stored, thereby avoiding the subsequent interference caused by the textile fabrics to the trimming machine and the phenomenon of loose edges of the textile fabrics, and further improving the efficiency and quality of textile fabric trimming. It includes a bracket module 1, Cutting module 2 and blanking module 3; Described support module 1 comprises cutting table, and described cutting table is supported by support bar 11, and the top surface of described cutting table is horizontal plane; On described cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com