An x-shaped elastic support structure with a socket connector

An elastic support and connector technology, which is used in the installation of cables, busbars, electrical components, etc., can solve the problems of large volume of supporting shrapnel, complicated assembly operations, and small diameter of elastic limit rings, so as to improve the plug contact. Conductive performance, shunt current performance is stable and reliable, easy installation management and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

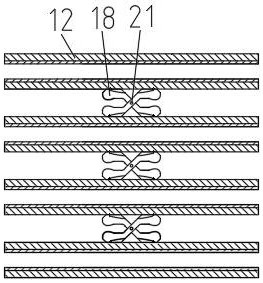

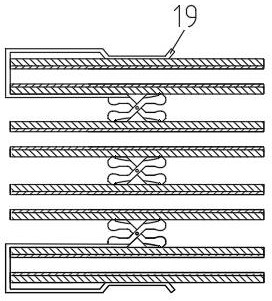

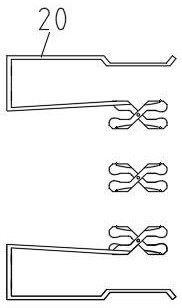

[0017] As shown in the figure, an X-shaped elastic support structure with a socket connector includes a number of interval distribution, the central part is sequentially penetrated by the joint bolt 4 and then connected with the joint nut 5. Multi-layer insulating partitions and multi-phase conductor connecting pieces The main body of the connector is formed. The outer part of the main body of the connector is provided with a protective shell composed of a connector cover plate 7 and a connector side plate 3. The connecting piece of each phase conductor is in contact with the phase conductor 14 at the corresponding position of the bus duct, and is located on the left and right sides. The insulating partition at the outermost position on the side is pressed tightly with the pressure plate 8 through the butterfly spring 6, and is connected with the joint side plate 3 of the bus duct through the pressure plate 8. The upper and lower ends of the pressure plate 8 and the joint side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com