Overturning device of upper die for die spotting hydraulic press

A technology of turning device and grinding machine, which is applied in the direction of grinding machine parts, manufacturing tools, grinding feed movement, etc., can solve the problems of high manual labor intensity, unsafety, low maintenance efficiency, etc., and achieve avoidance of interference, Reduce the impact and ensure the effect of smooth detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the present invention, the components without specific structures and connection methods are usually conventional components or connection methods.

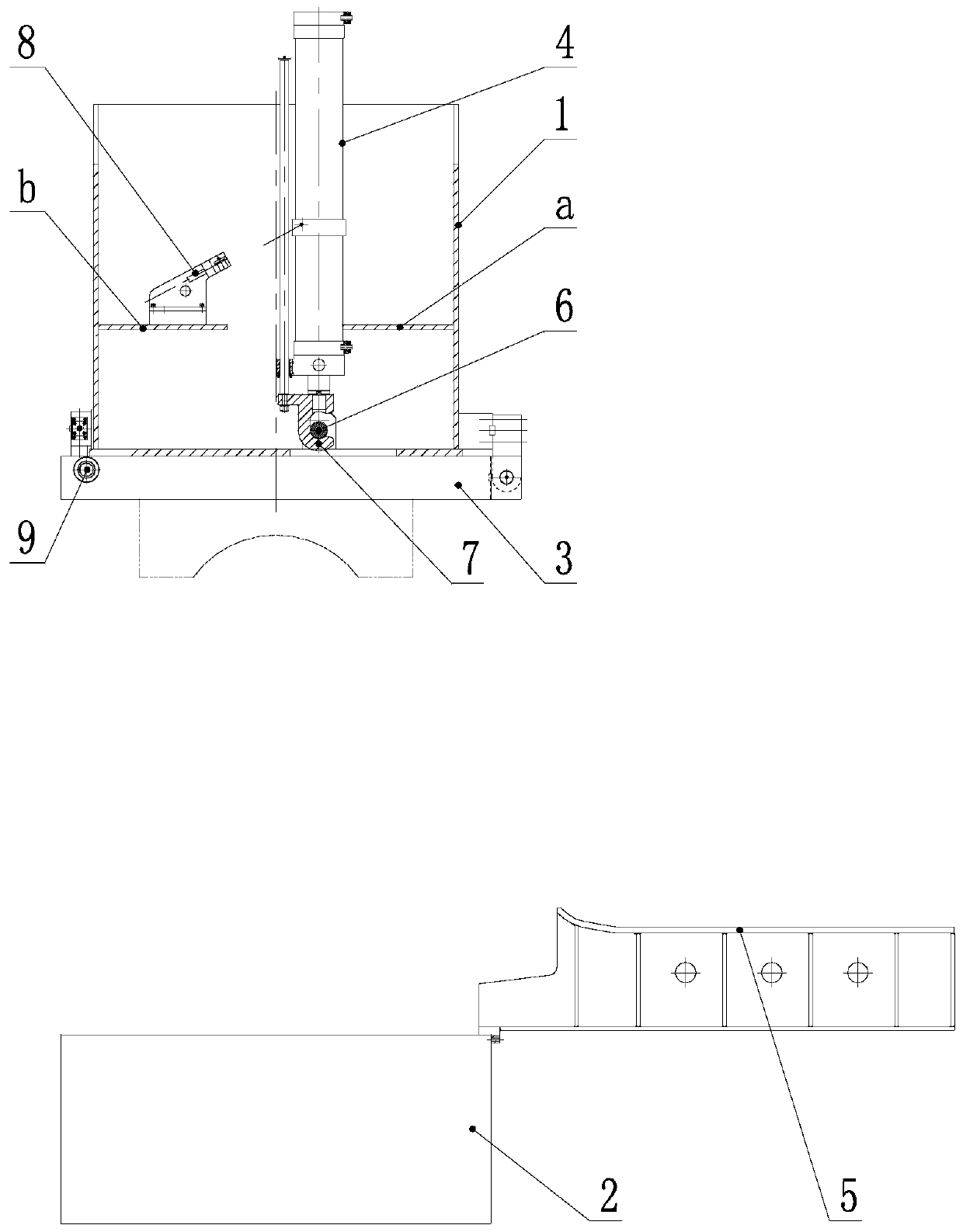

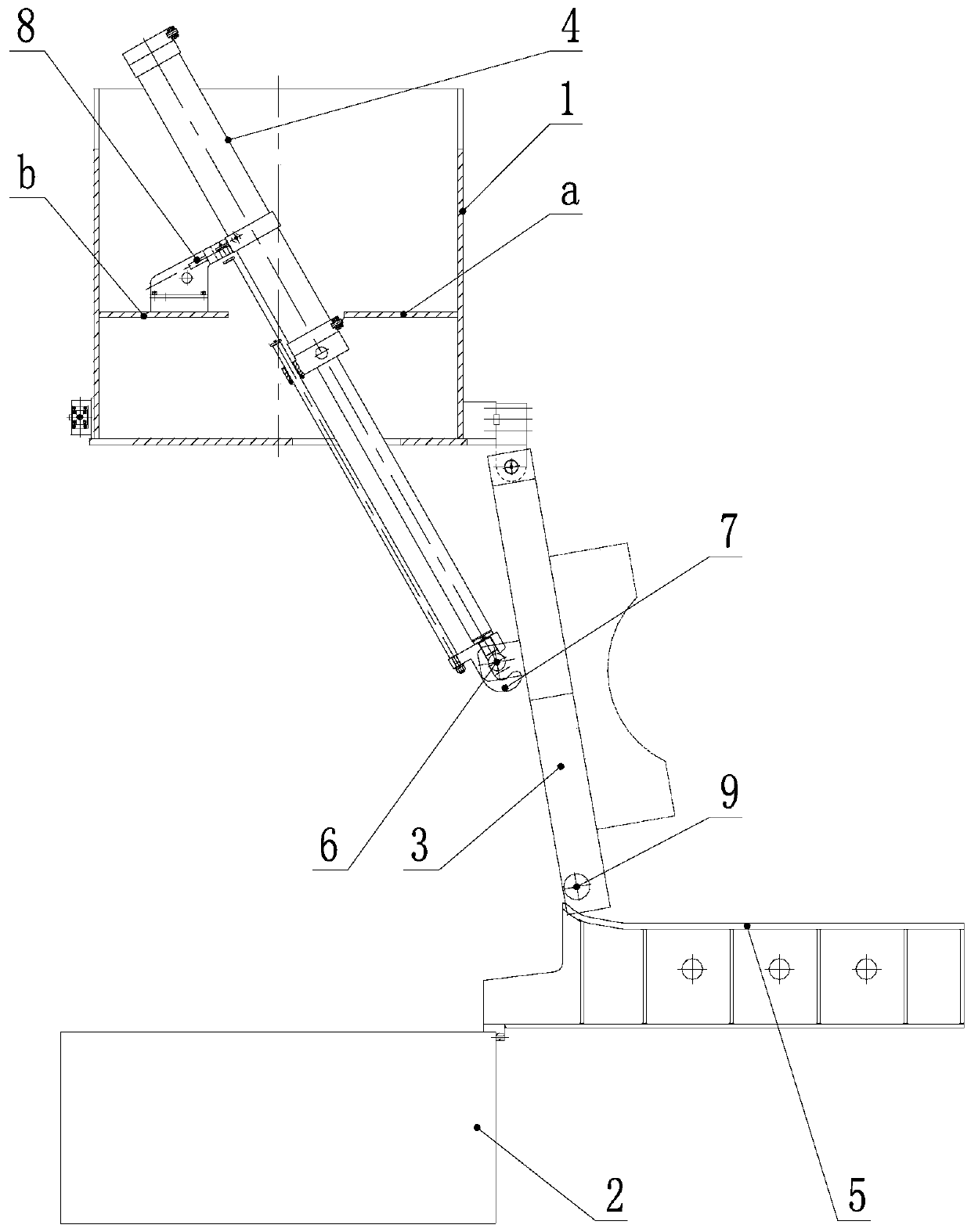

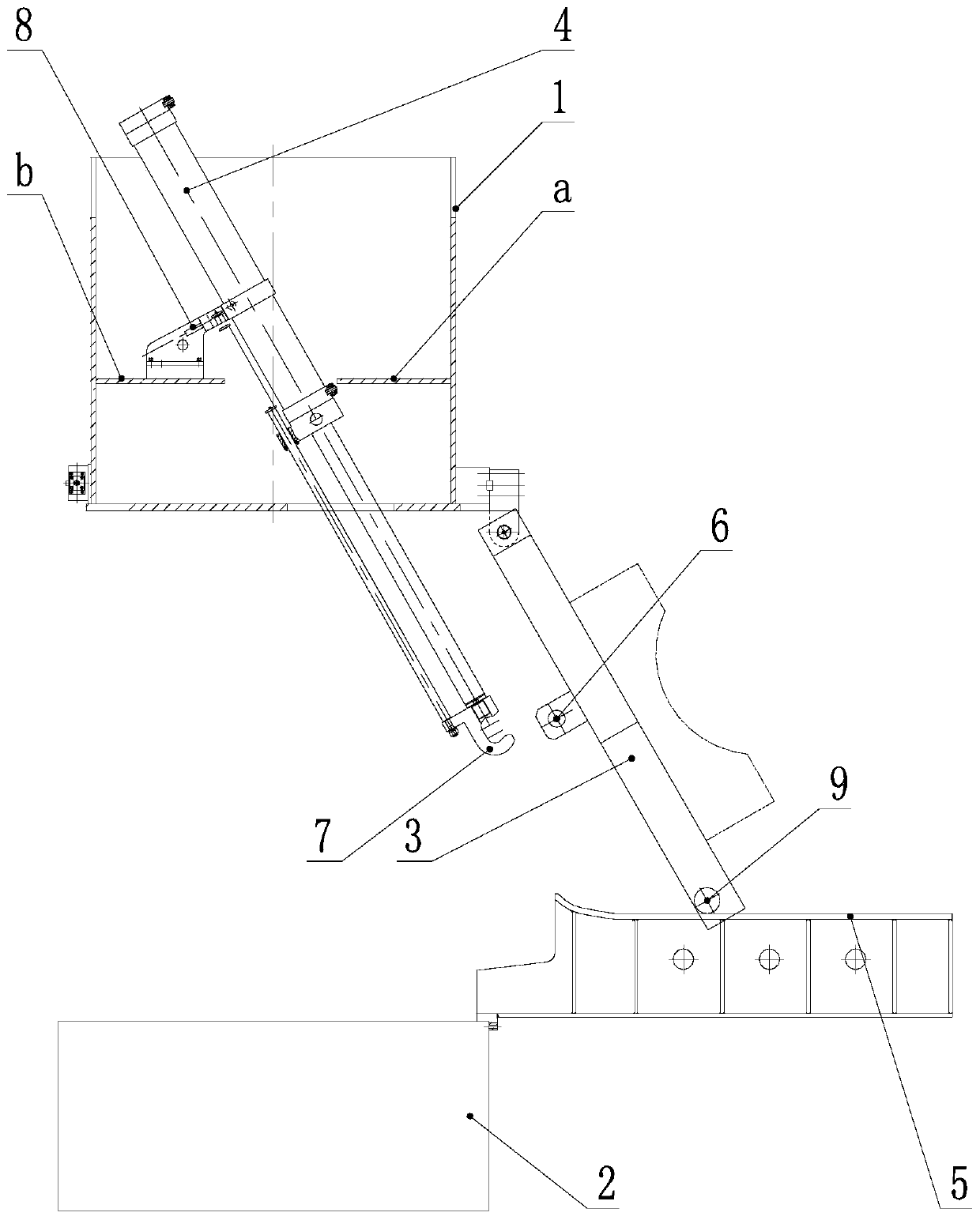

[0028] see Figure 1 to Figure 5 , which is a specific embodiment of an overturning device for an upper mold of a mold grinding and matching machine. The overturning device of the upper mold of the mold research and matching machine includes a research and matching machine slider 1 and a research and matching machine base 2. The movement in the vertical direction, the sliding block of the research and matching machine and the base of the research and matching machine are the matching parts of the research and matching machine. It also includes a turn-over plate 3, a turn-over telescopic cylinder 4, and a turn-over plate guide rail 5. The turning plate 3 is located below the slider 1 of the researching and blending machine, the hinged end of the turning plate 3 is hinged to one side of the slider 1 of the researching a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com