Method for quickly determining installation angle of aircraft wing

A technology for installing angles and wings, which is applied to aircraft assembly, aircraft parts, ground devices, etc., can solve the problems of long calculation cycle, aerodynamic calculation or wind tunnel test workload, long cycle, etc., so as to save workload and simplify The effect of the wing installation angle determination procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. For simplicity, some technical features known to those skilled in the art are omitted from the following description.

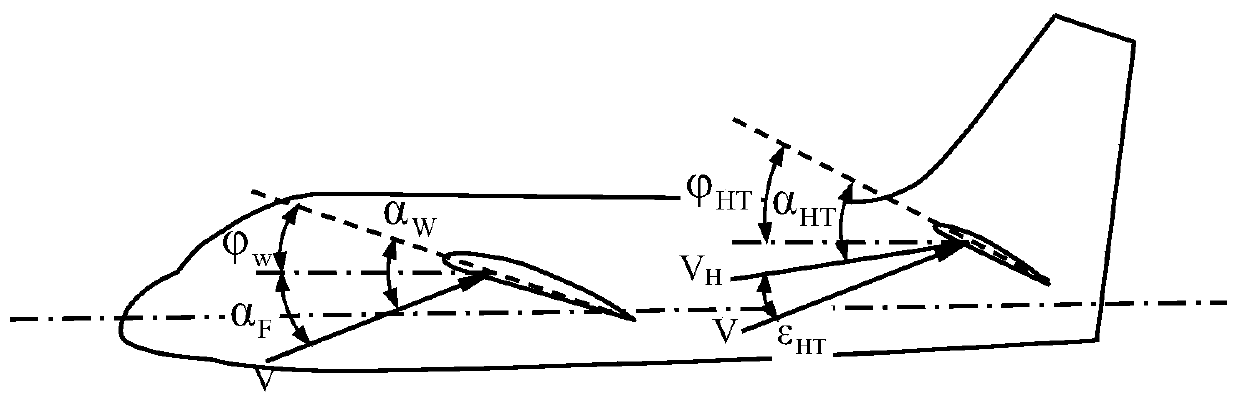

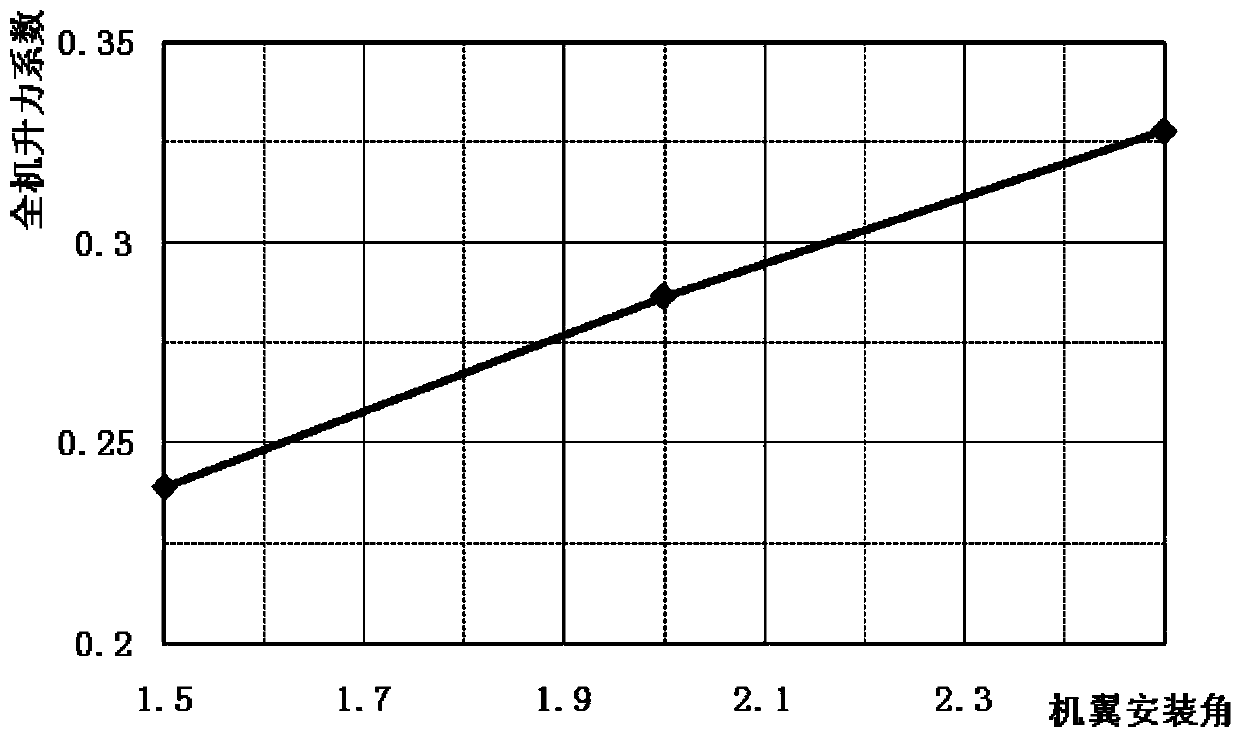

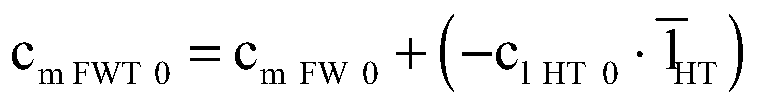

[0033] In a certain implementation case, the present invention decomposes the overall aerodynamic characteristics of a civil aircraft with conventional layout into the aerodynamic characteristics of the wing / body assembly and the flat tail aerodynamic characteristics, based on the cruise design point conditions, that is, the cruise lift coefficient is given and the pitch angle of the fuselage is zero 1. The pitching moment of the whole aircraft is zero. Through appropriate assumptions, the pitching moment and lift characteristic data of the wing / body assembly at zero angle of attack are reasonably used to quickly determ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap