Telescopic mechanism, camera device and terminal

A telescopic mechanism and telescopic part technology are applied in the fields of camera devices, terminals, and telescopic mechanisms, which can solve problems such as poor user experience, increased action process, and unsightly appearance, and achieve the effect of improving aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

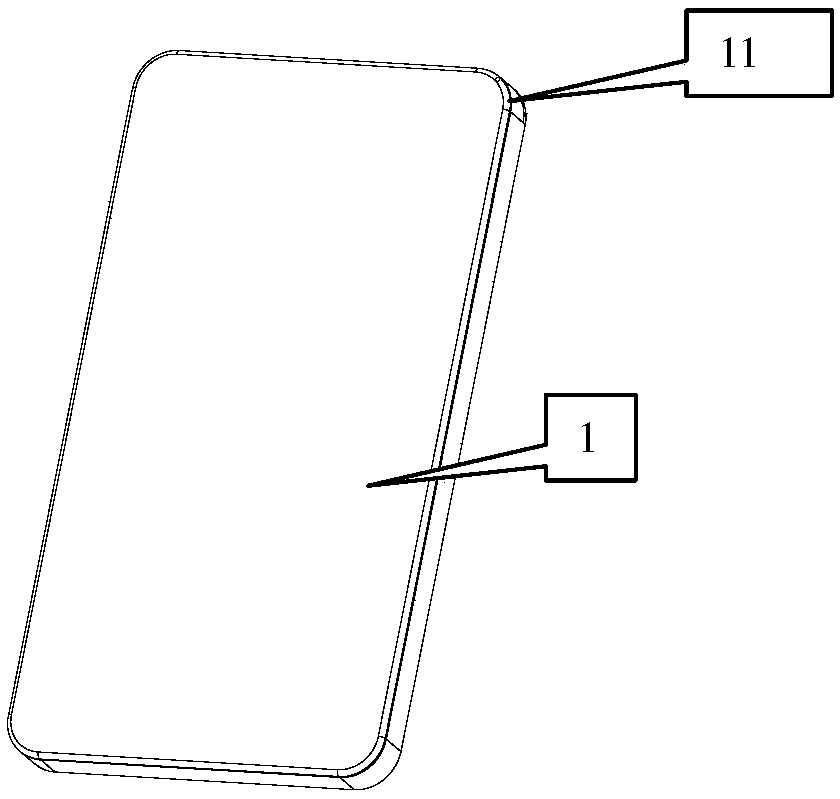

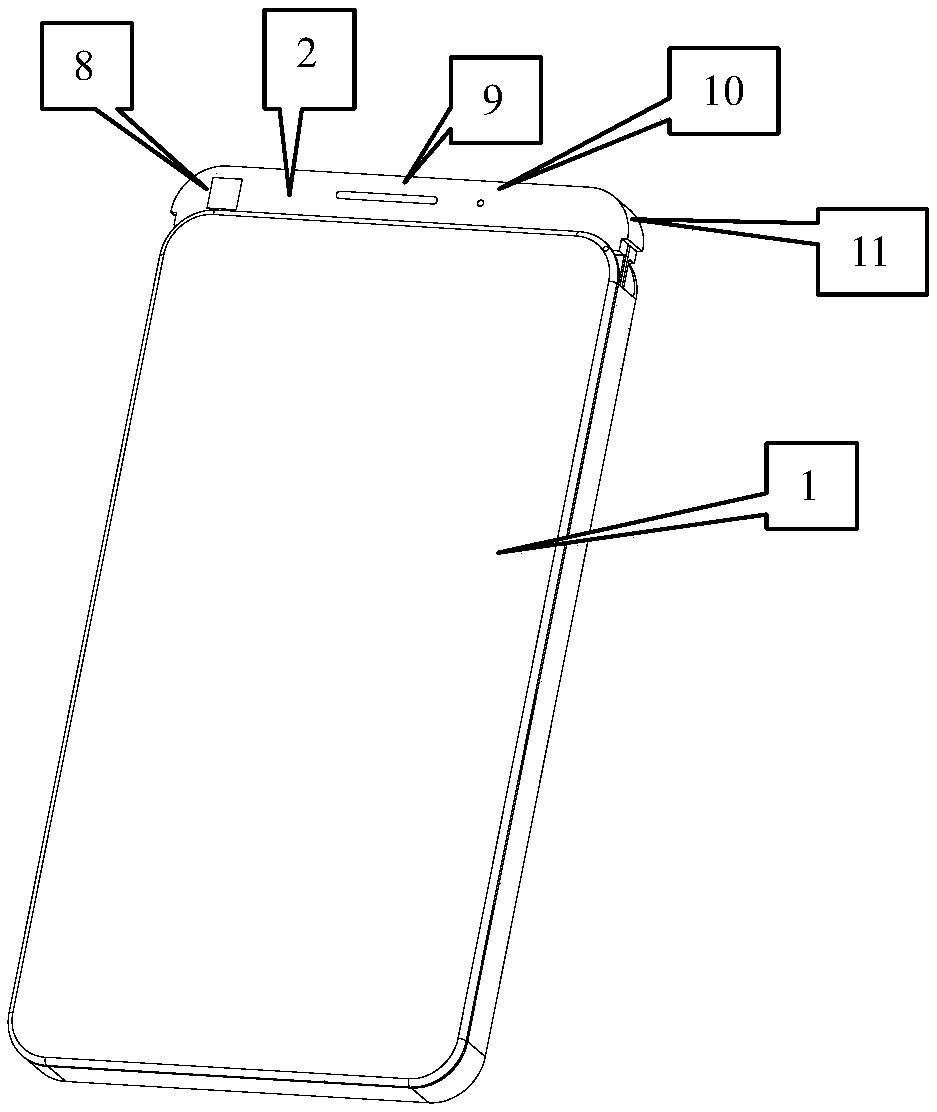

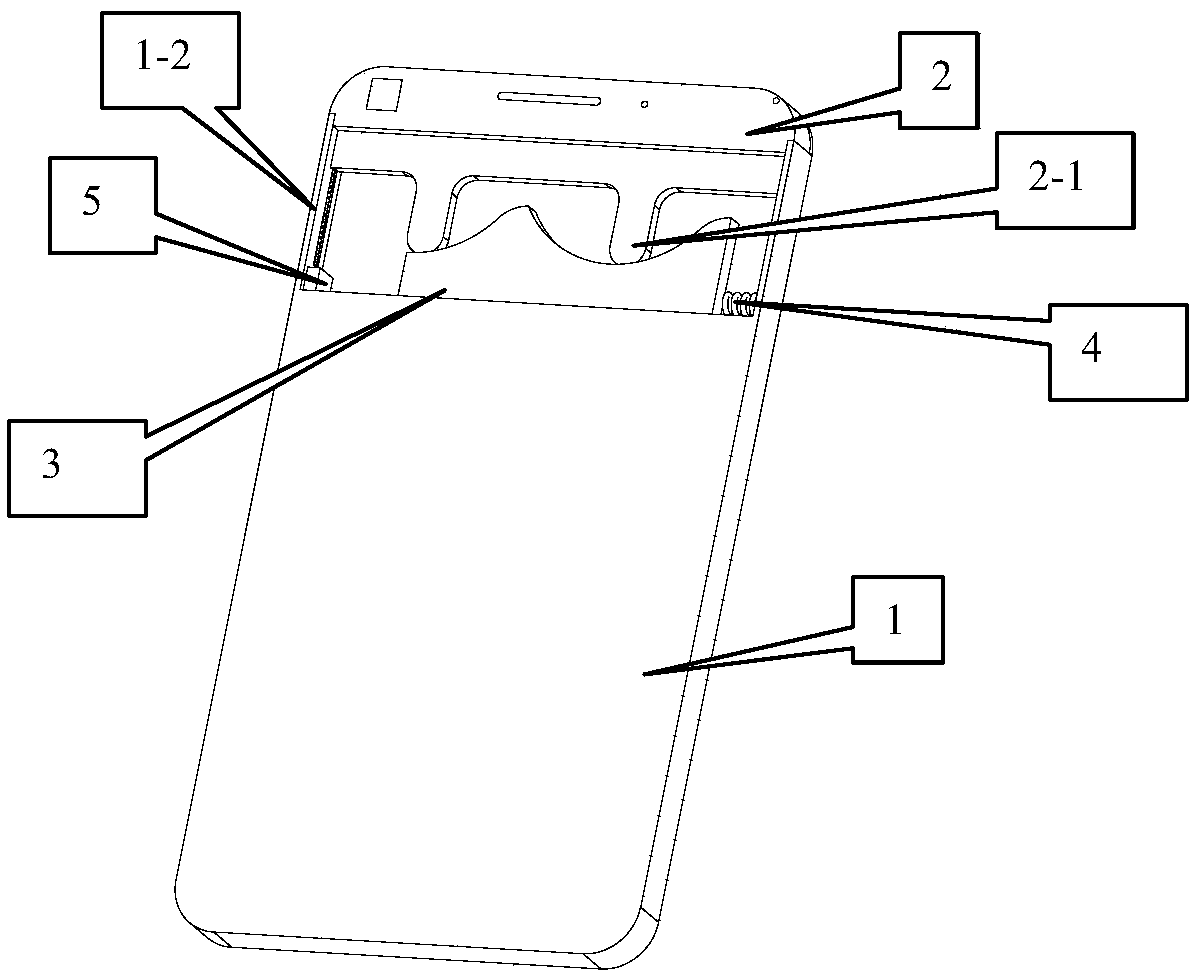

[0022] The first embodiment of the present invention provides a telescopic mechanism, the telescopic mechanism includes a telescopic part and an accommodating groove for accommodating the telescopic part, the telescopic part can protrude out of the accommodating groove, and can also be retracted Hidden in the accommodating groove; the accommodating groove is provided with a telescopic driving part that drives the telescopic part to extend or retract the accommodating groove; the telescopic driving part includes an electromagnet, The telescopic mechanism controls the extension or retraction of the telescopic part by controlling the energization or de-energization of the electromagnet. In the telescopic mechanism provided by the embodiment of the present invention, the telescopic power comes from the electromagnet, and the electromagnet occupies a small space, and is easy to control and low in cost.

[0023] It should be noted that, in the description of the embodiments of the p...

no. 2 example

[0044] On the basis of the first embodiment of the present invention, the second embodiment of the present invention proposes another telescoping mechanism. The realization of the telescopic mechanism of the second embodiment of the present invention is basically similar to that of the first embodiment of the present invention. The differences include : The moving direction of the telescopic guide block, which will be described in detail below.

[0045] Here, the telescopic driving part may include a first electromagnet, a telescopic guide block, and a first return spring; the telescopic guide block is slidably disposed at the bottom of the accommodating tank, and can move based on the bottom of the accommodating tank, Here, the moving direction of the telescopic guide block is neither parallel nor perpendicular to the telescopic movement direction.

[0046] The top of the telescopic guide block is provided with an ejection structure that can push the telescopic part to perfor...

no. 3 example

[0049] On the basis of the first embodiment of the present invention, the third embodiment of the present invention proposes yet another telescoping mechanism. The difference between the third embodiment of the present invention and the telescopic mechanism of the first embodiment of the present invention lies in the setting of the telescopic drive components method, which will be described in detail below.

[0050] The telescopic driving part includes at least two electromagnets, and the telescopic mechanism controls the extension or retraction of the telescopic part by controlling the energization or de-energization of the electromagnets.

[0051] As an implementation, the telescopic driving part includes a second electromagnet, a third electromagnet, and a telescopic guide block; the telescopic guide block is slidably arranged at the bottom of the accommodating tank, and can Make a movement that is not parallel to the direction of the telescopic movement; one end of the tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com