PTC heater and manufacturing method thereof

A heater and manufacturing method technology, applied in the direction of heating element materials, etc., can solve the problems of poor product consistency, low power, high failure rate, etc., and achieve the effects of simplifying installation and connection steps, reducing production costs, and increasing heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

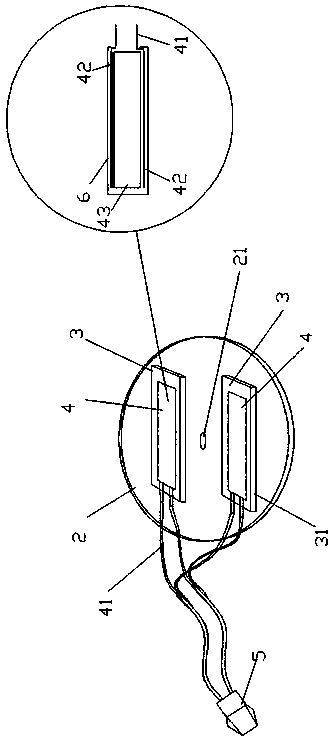

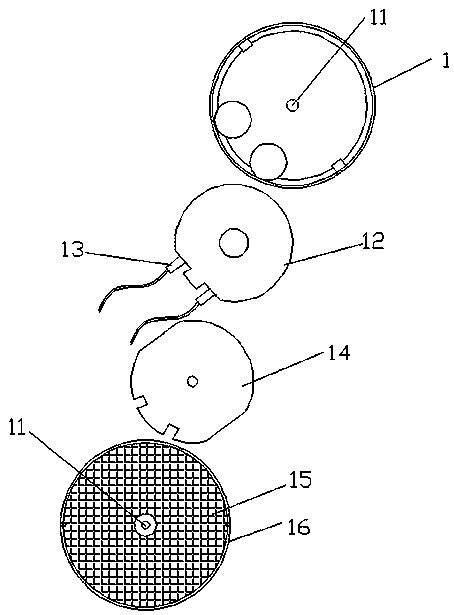

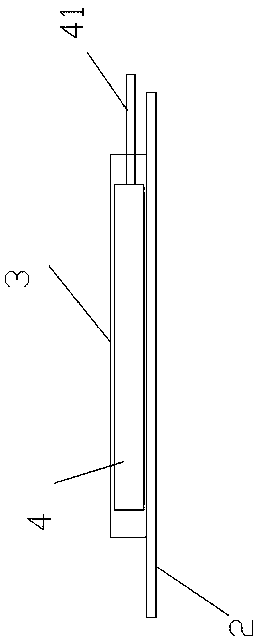

[0035] like figure 1 , 3 A PTC heater shown includes a heat-conducting aluminum plate 2 with a PTC heating unit 4 and a circular appearance shape. There is an aluminum-shaped card slot 3, which is equipped with a PTC heating unit 4. There are two aluminum-shaped card slots 3 to ensure uniform heating. The aluminum-shaped card slot 3 includes a cover plate 32 and a connecting cover plate 32. The clamping position 31 on the side, the clamping position 31 is located on the heat-conducting aluminum plate 2, forming a hollow structure transparent from front to back, and its size is adapted to the PTC heating unit 4. Described PTC heating unit 4 comprises PTC heating sheet 43, insulating paper 6 and electrode sheet 42, and described electrode sheet 42 is arranged on the upper and lower surface of PTC heating sheet 43 respectively, and the integral body of described electrode sheet 42 and described PTC heating sheet 43 wrapped in the insulating paper 6 . The aluminum-shaped card s...

Embodiment 2

[0048] Such as Figure 5 The structure of the clamping position 31 in the manufacturing method of the PTC heater described in this embodiment can also be inclined in the same direction as a whole, and the parallel inclination in the same direction can ensure the uniformity of the pressure on the whole. It will cause the aluminum groove to deform under the action of pressure.

Embodiment 3

[0050] Such as Image 6 The structure of the clamping position 31 in the manufacturing method of the PTC heater described on the basis of not changing other structures in this embodiment can also adopt the convex shape of the middle part to facilitate the pressing down of the aluminum-type card slot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com