Brake shoe assembly with wireless alarm function

A technology of wireless alarms and brake shoes, applied in the types of brakes, mechanical equipment, etc., can solve problems such as driving hazards, waste, and endangering the safety of drivers and passengers, and achieve timely alarms, simple manufacturing, and high alarm accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

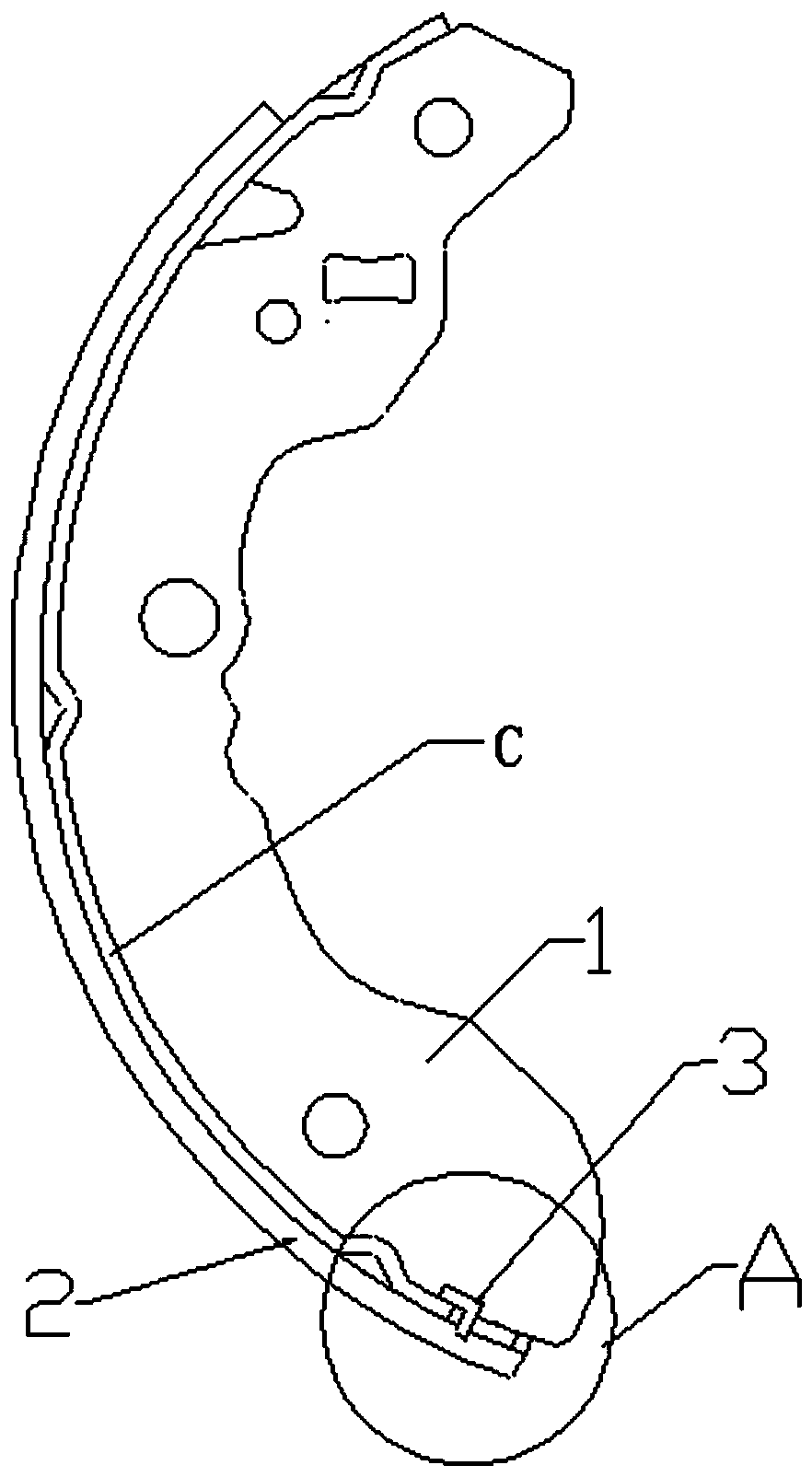

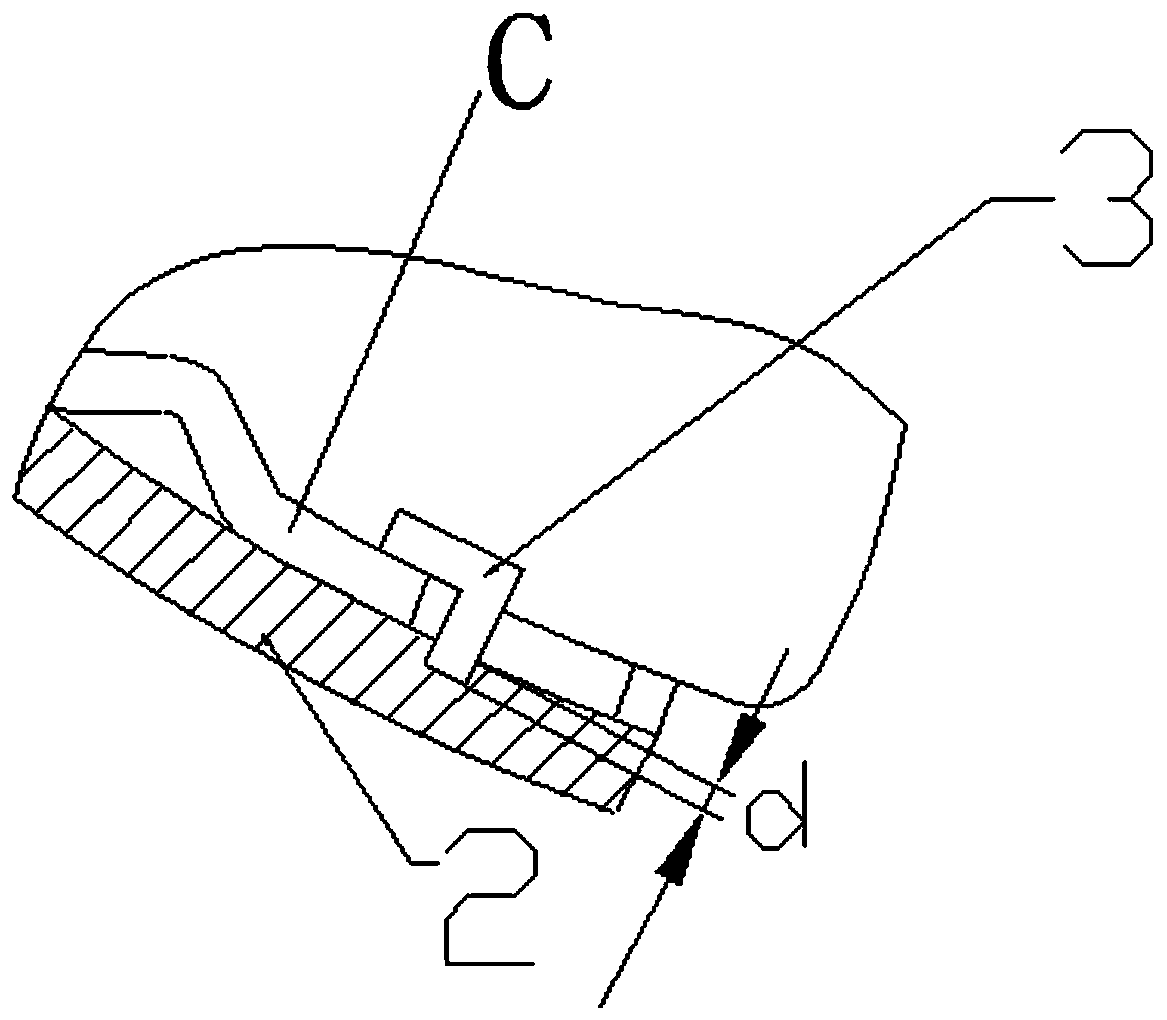

[0025] like figure 1 , 2 As shown, the wireless alarm is set on the inner surface C of the brake shoe 1 and its detection end part extends into the friction lining 2 . At this time, the wireless alarm 3 can be fastened on the inner circular surface C of the brake shoe 1 through the connecting piece, and the detection end can be extended into the friction lining 2 for a certain distance d, which is convenient for installation. It can also guarantee the detection accuracy.

[0026] The wireless alarm 3 installed on the brake shoe 1 can actively monitor the thickness of the friction lining 2. When the remaining thickness of the friction lining 2 reaches the alarm requirement, the wireless alarm 3 sends a wireless signal and transmits it to the dashboard of the cab. Remind the driver to replace the friction plate body.

Embodiment 2

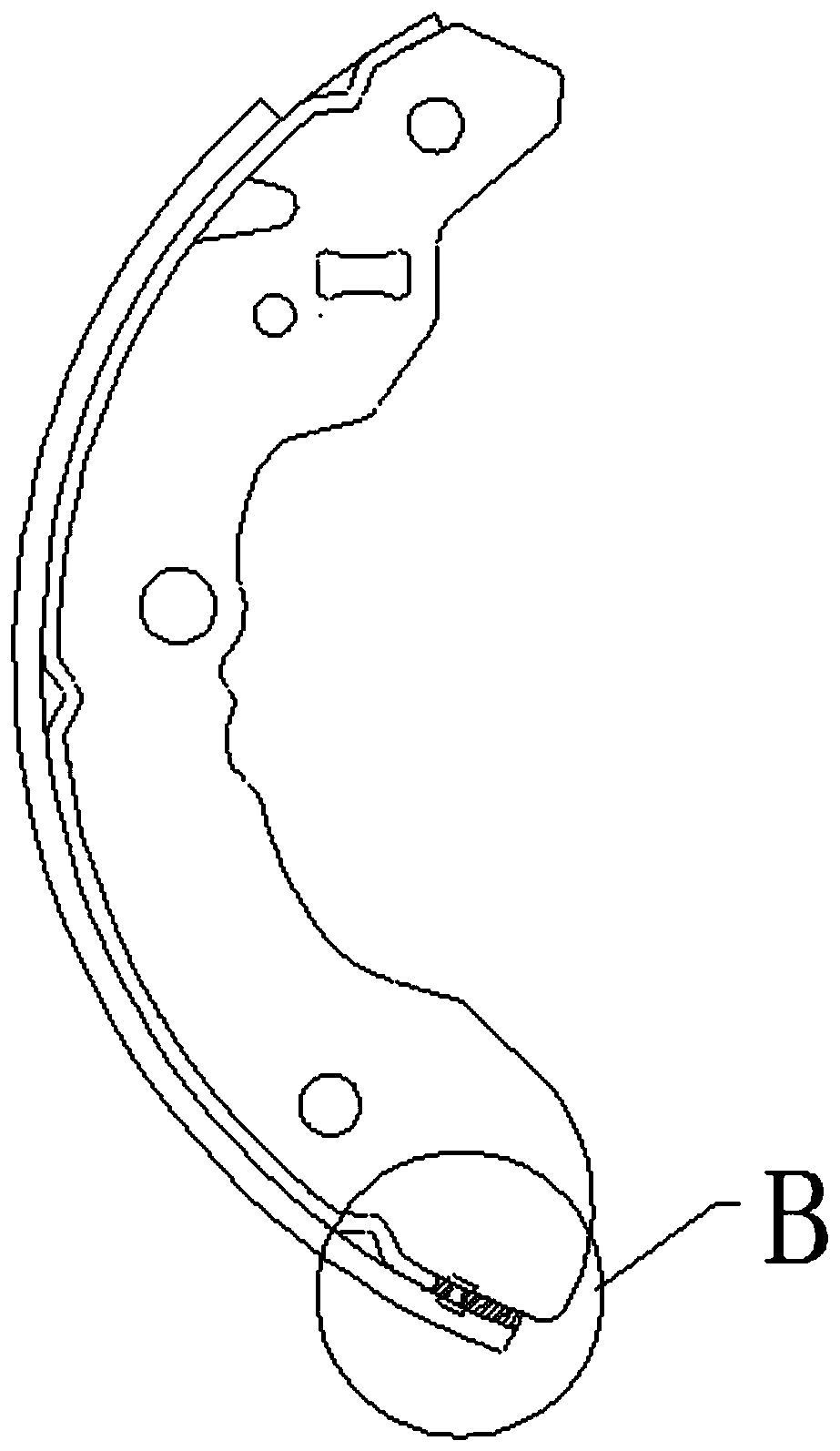

[0028] like image 3 , 4 As shown, an installation position can also be set on the inner circular surface C of the brake shoe 1, and the wireless alarm 3 can be set in the installation position; it should be noted that the friction lining 2 should be covered above the installed position . Then the wireless alarm 3 is connected and fastened with the brake shoe 1 and the friction lining 2 by fasteners.

Embodiment 3

[0030] The wireless alarm 3 can also be arranged inside the friction lining 2 . In such an arrangement, an installation groove can be correspondingly provided on the friction lining 2; the installation groove is provided on the side adjoining the inner circular surface C of the brake shoe.

[0031] By adding a wireless alarm to the brake shoe assembly, when the friction lining wears to the limit thickness, the wireless alarm will send an alarm signal to the instrument panel after detection. Its alarm accuracy is high and the alarm is timely; at the same time, its production process only needs to use the traditional manufacturing process, and there is no need to modify the traditional brake parts in the realization of the overall braking, and the manufacture is simple, safe and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com