A server and its hard disk quick disassembly heat dissipation composite module

A composite mold and hard disk technology, applied in the server field, can solve the problems of M.2 hard disk cooling efficiency not guaranteed, fast read and write speed, cold air is difficult to reach, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

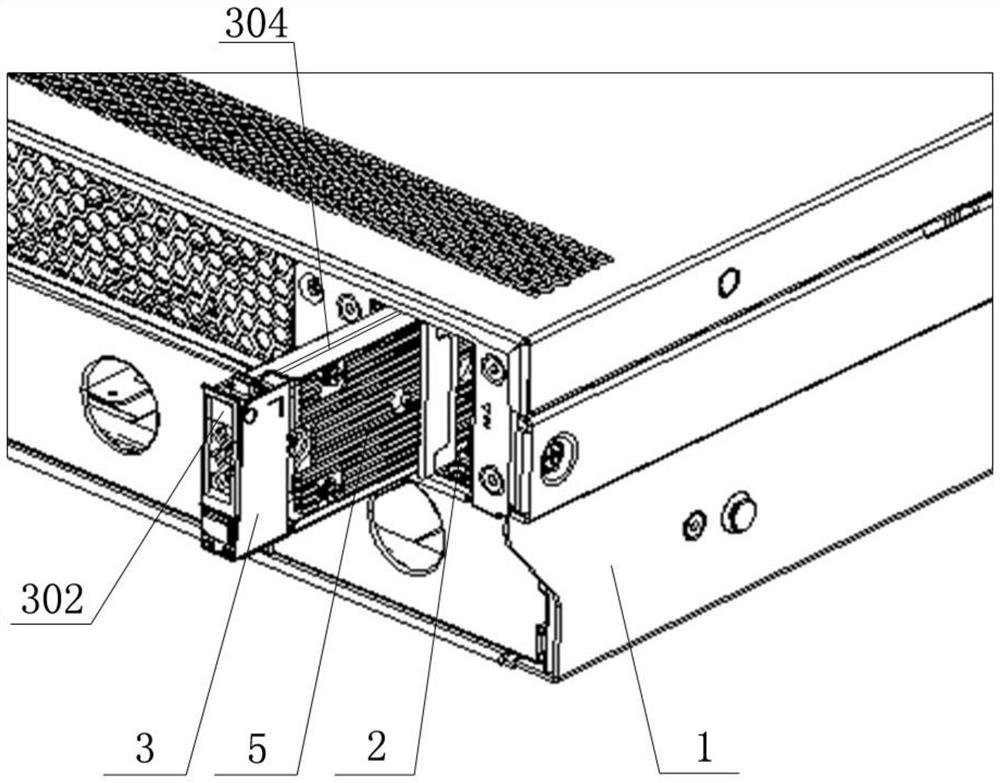

[0038] Please refer to figure 1 , figure 1 A schematic structural diagram of a hard disk quickly disassemble the heat dissipation composite module and the chassis 1 in accordance with a specific embodiment of the present invention.

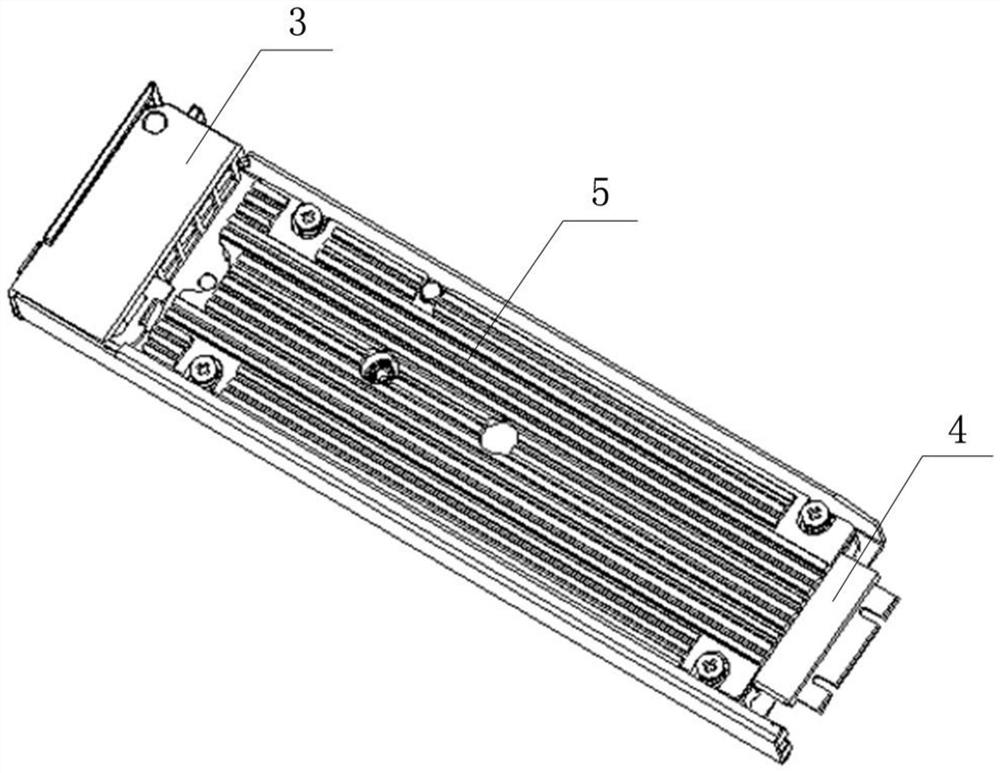

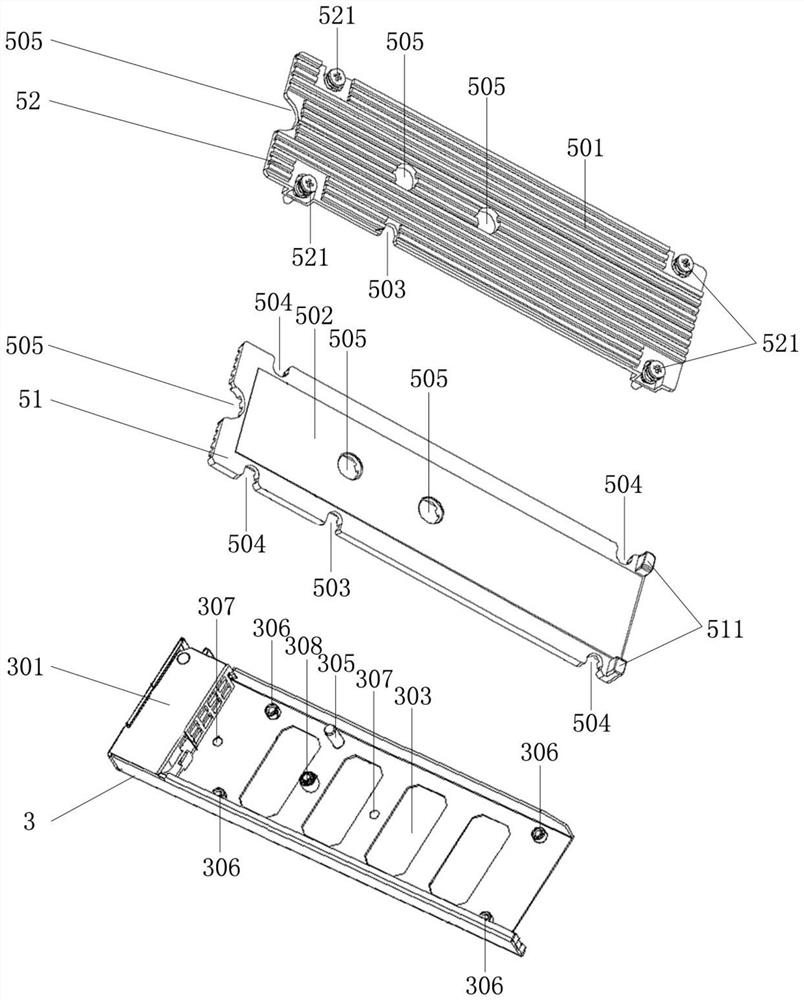

[0039] In a particular embodiment of the invention, the hard disk is quickly disassemble the heat dissipation composite module, mainly including mounting bracket 3, storage hard disk 4, and heat sink.

[0040] Among them, the mounting bracket 3 is the main structure of the hard disk quickly disa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com