Preparation method of stretchable composite electrode

A composite electrode and pre-stretching technology, which is applied in the direction of battery electrodes, electrode carriers/current collectors, circuits, etc., to achieve the effect that it is not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

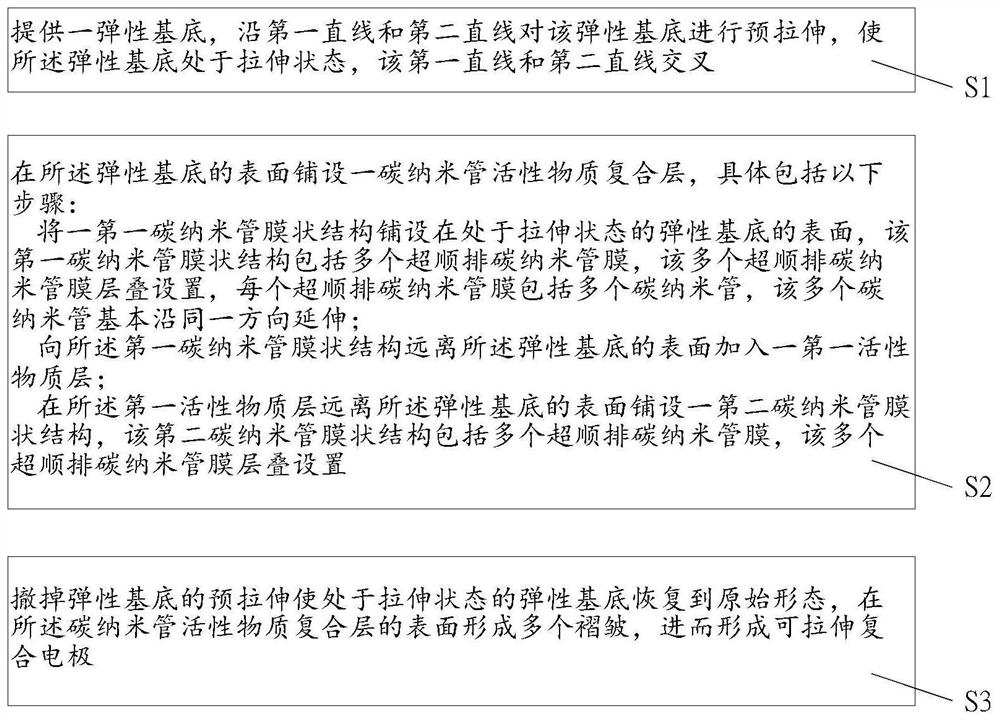

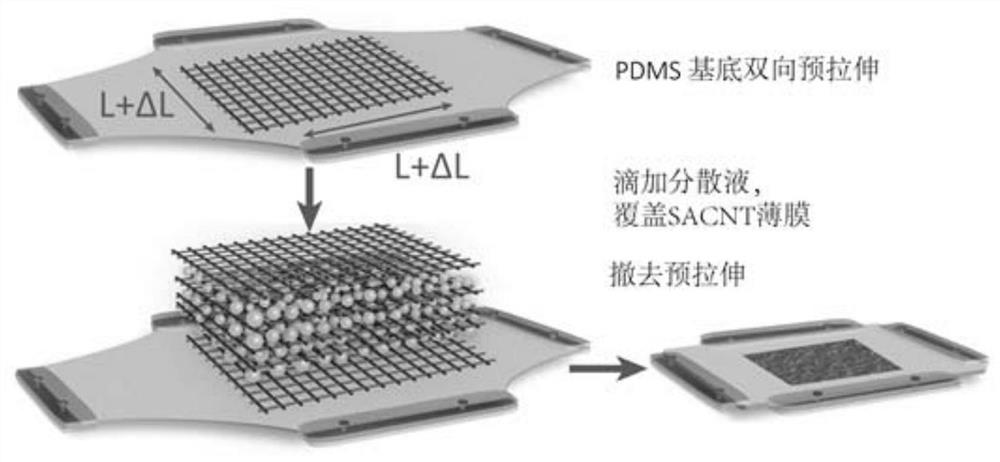

[0049] see figure 1 and 2 , an embodiment of the present invention provides a method for preparing a stretchable composite electrode, comprising the following steps:

[0050] Step S1, providing an elastic base, pre-stretching the elastic base along a first direction and a second direction, so that the elastic base is in a stretched state, and the first direction and the second direction intersect;

[0051] Step S2, laying a carbon nanotube active material composite layer on the surface of the elastic substrate, specifically includes the following steps:

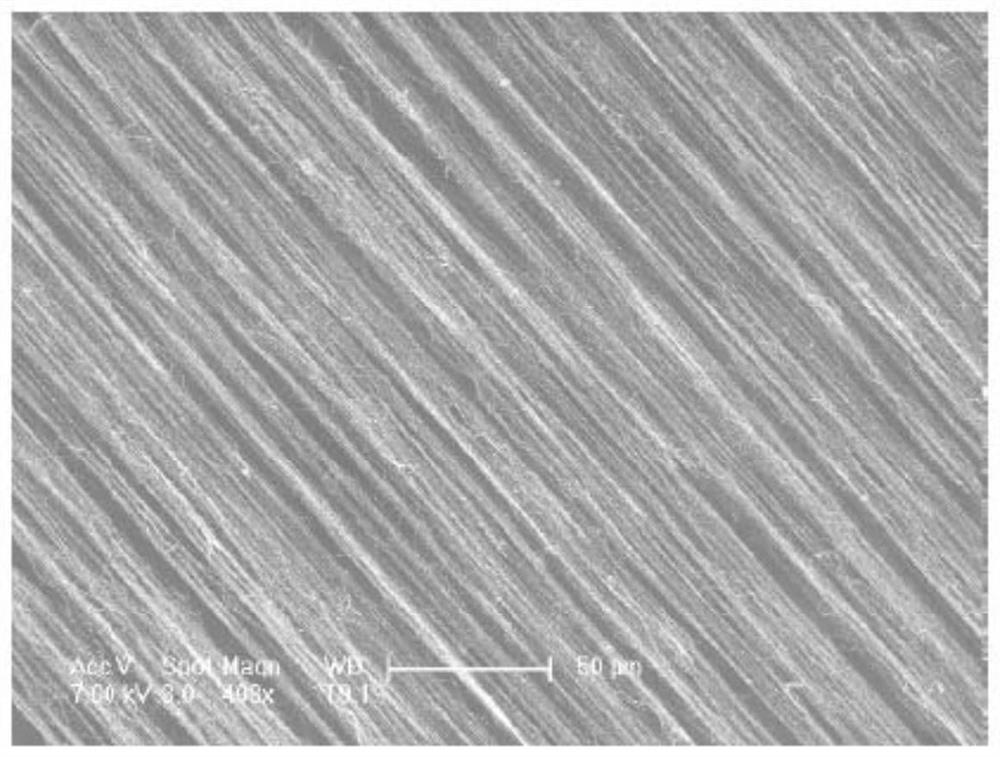

[0052] S21, laying a first carbon nanotube film-like structure on the surface of the elastic substrate in a stretched state, the first carbon nanotube film-like structure includes a plurality of super-aligned carbon nanotube films, and the plurality of super-aligned carbon nanotube films The carbon nanotube films are stacked, and each super-aligned carbon nanotube film includes a plurality of carbon nanotubes, and the plura...

Embodiment 1

[0080] In this embodiment, a stretchable PDMS / super-parallel carbon nanotube film / Li(NiCoMn) is prepared 1 / 3 o 2 Composite positive electrode, its preparation method comprises: providing a rectangular PDMS substrate with a thickness of 7mm, carrying out 150% pre-stretching to the PDMS substrate along the length and width of the rectangular PDMS substrate respectively; The 6-layer super-parallel carbon nanotube cross film is covered on the PDMS substrate in the stretched state; 45mg Li(NiCoMn) 1 / 3 o 2 The active substance was dispersed in 60mL ethanol (10% power, 45min) using a cell pulverizer to form a dispersion, and 6mL of the dispersion was evenly added dropwise to the 6-layer super-parallel carbon nanotube cross-membrane using a pipette gun. Formation of Li(NiCoMn) after evaporation of ethanol to no obvious liquid droplets 1 / 3 o 2 Active material layer; in Li(NiCoMn) 1 / 3 o 2 The active material layer is covered with 2 layers of super-parallel carbon nanotube intersec...

Embodiment 2

[0082] In this embodiment, a stretchable PDMS / super-parallel carbon nanotube film / Li 4 Ti 5 o 12 Composite negative electrode, its preparation method is basically the same as embodiment 1, and its difference is only that active material layer is Li 4 Ti 5 o 12 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com