Clamping and rotating device for stainless steel insulation cups

A technology for clamping, rotating, thermos cups, applied in the direction of injection devices, etc., which can solve the problems of looseness, unsuitability of thermos cups, processing errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

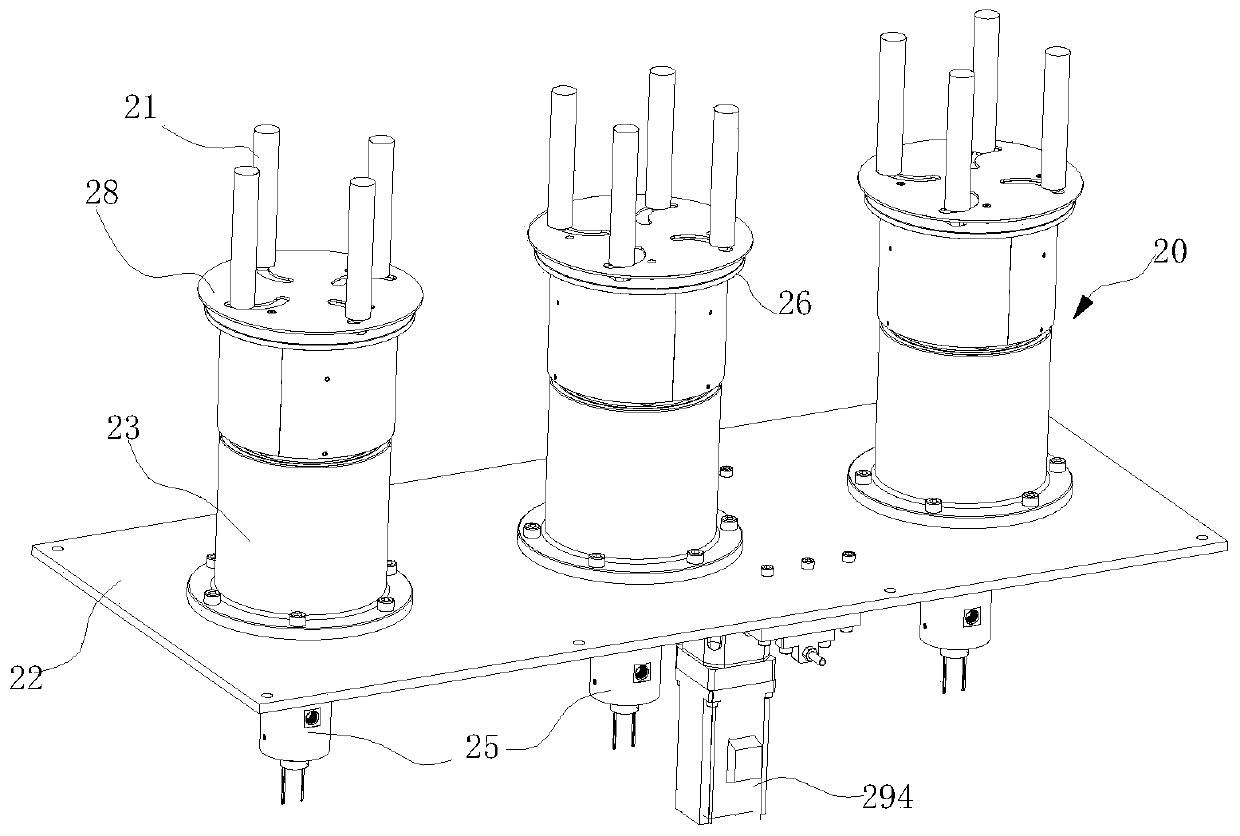

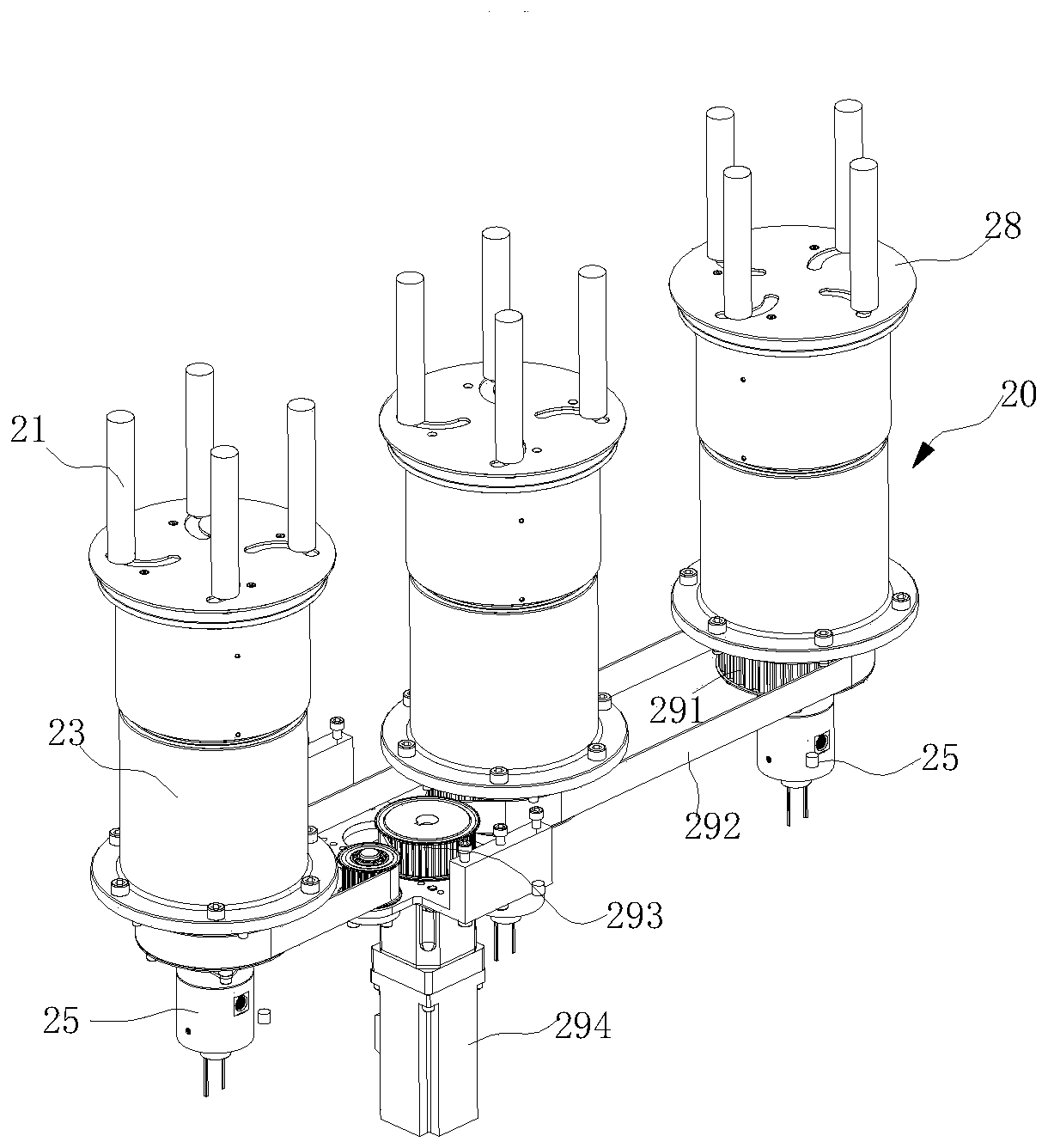

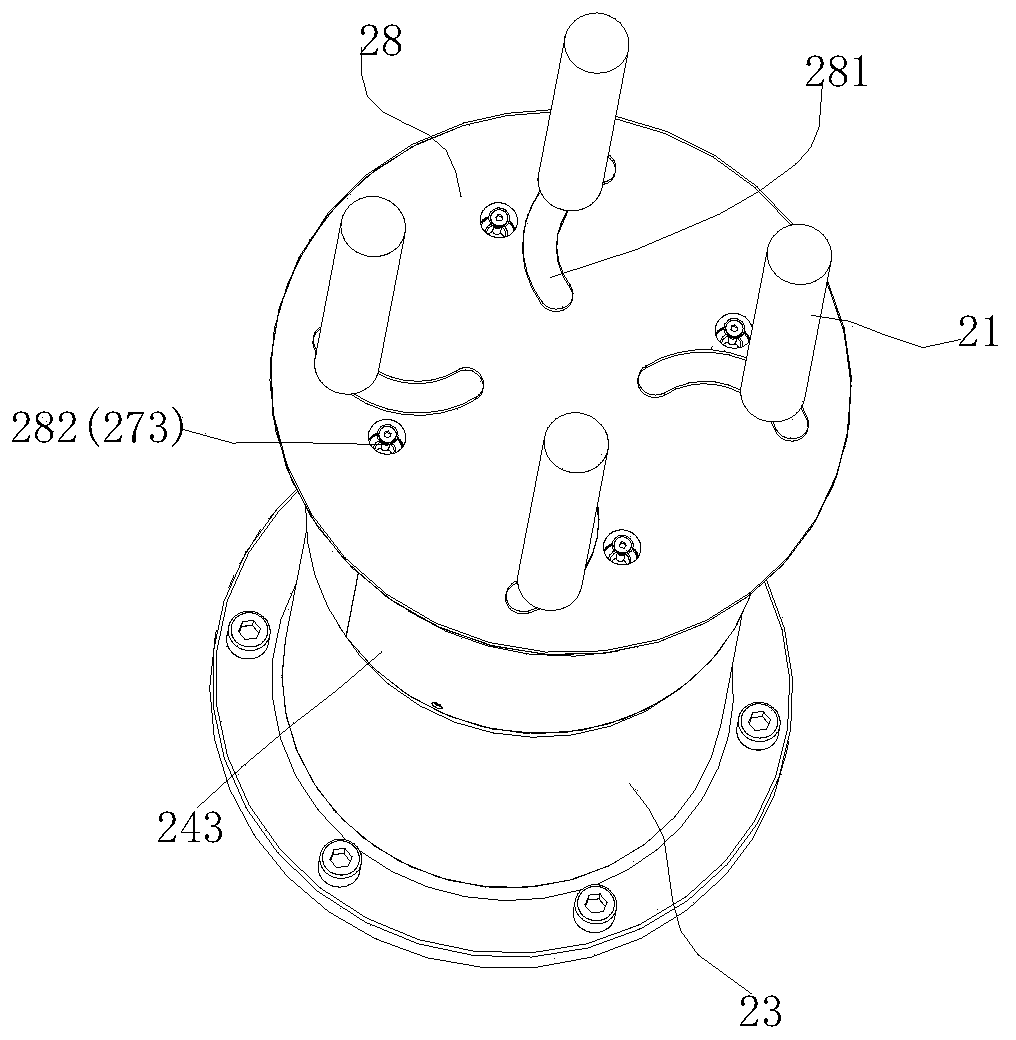

[0010] Combine below Figure 1-Figure 8 The present invention is discussed in further detail.

[0011] A clamping and rotating device for a stainless steel thermos cup, comprising at least three clamping rods 21 whose rod cores are located in a vertical plane, each clamping rod 21 translates in the radial direction and the rod of each clamping rod 21 The cylinder formed by the core and the surrounding always has a common core, and the drive unit drives the clamping rod 21 to rotate around the core of the cylinder. According to the outer diameter of different stainless steel thermos cups, each clamping rod 21 is moved in the radial direction to clamp the stainless steel thermos cup, each clamping rod 21 moves synchronously at the same time, and the cylinder formed by the rod core of each clamping rod 21 is always Common core, so as to ensure that the axis core of the stainless steel thermos cup clamped on it is determined and stable, and the drive unit drives the clamping rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com