Label paper carrier

A technology of labeling paper and carrier, applied in labeling, labeling machines, packaging, etc., can solve the problems of inability to obtain higher heights and limited application range, and achieve the effect of large lifting height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

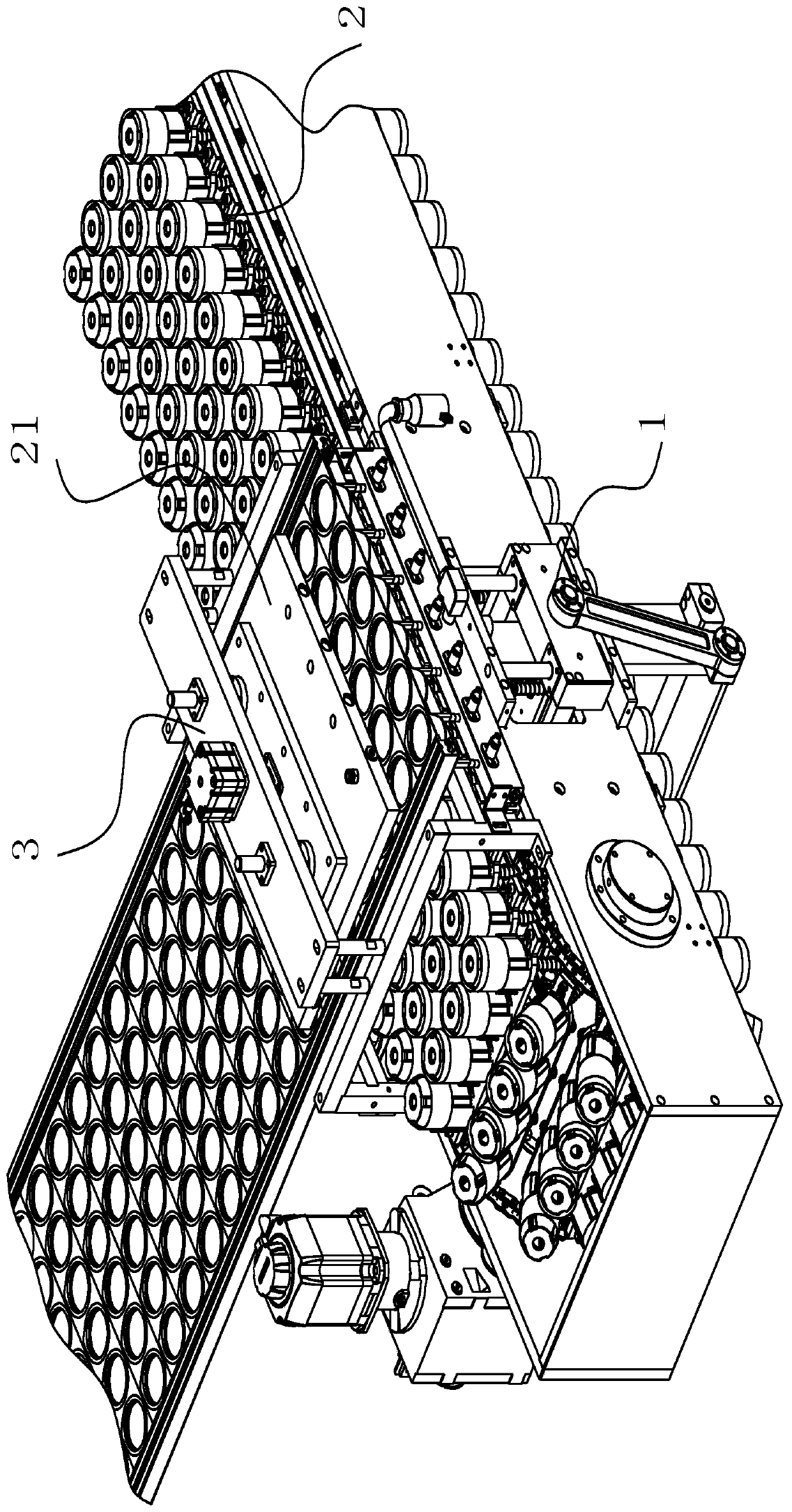

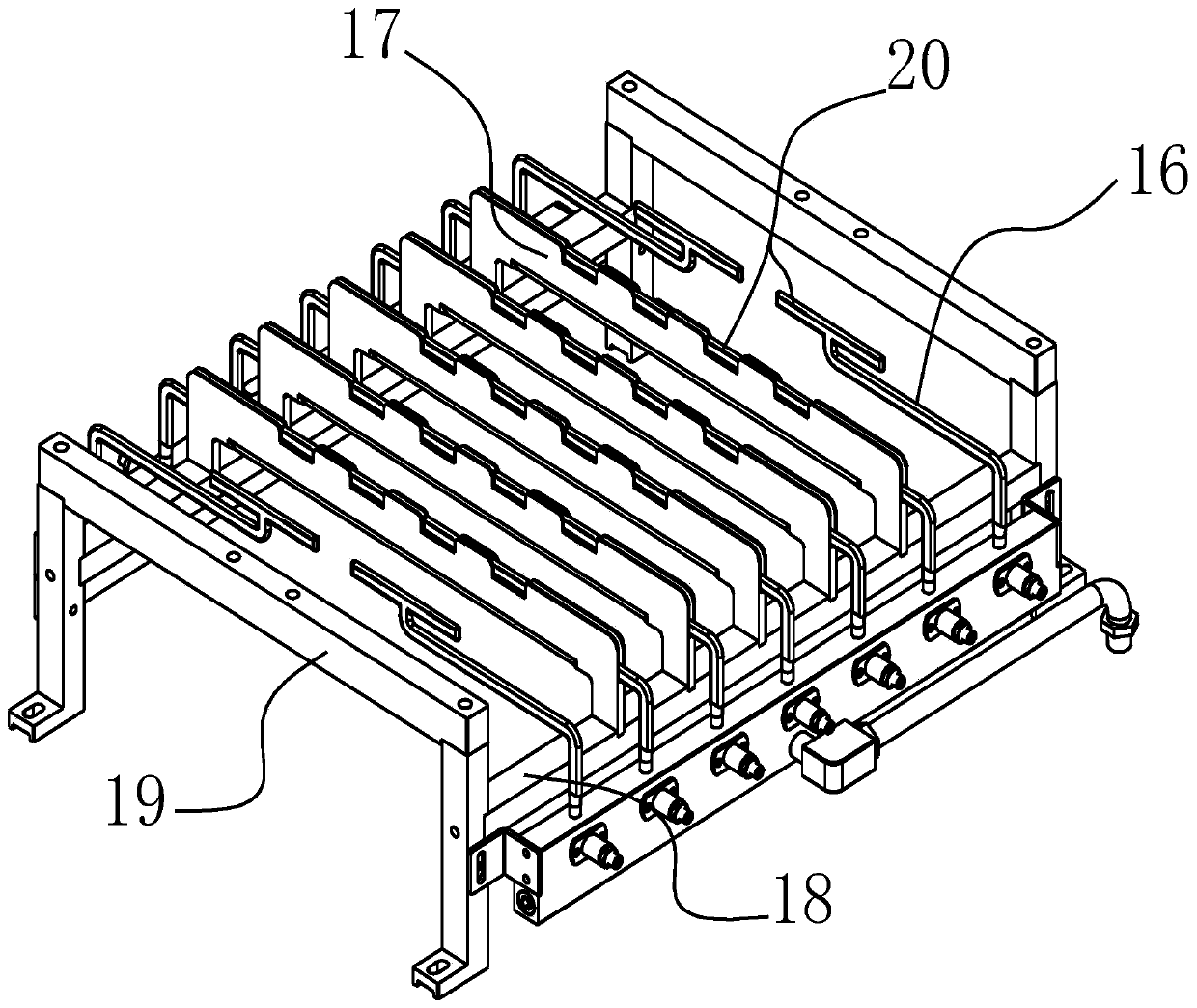

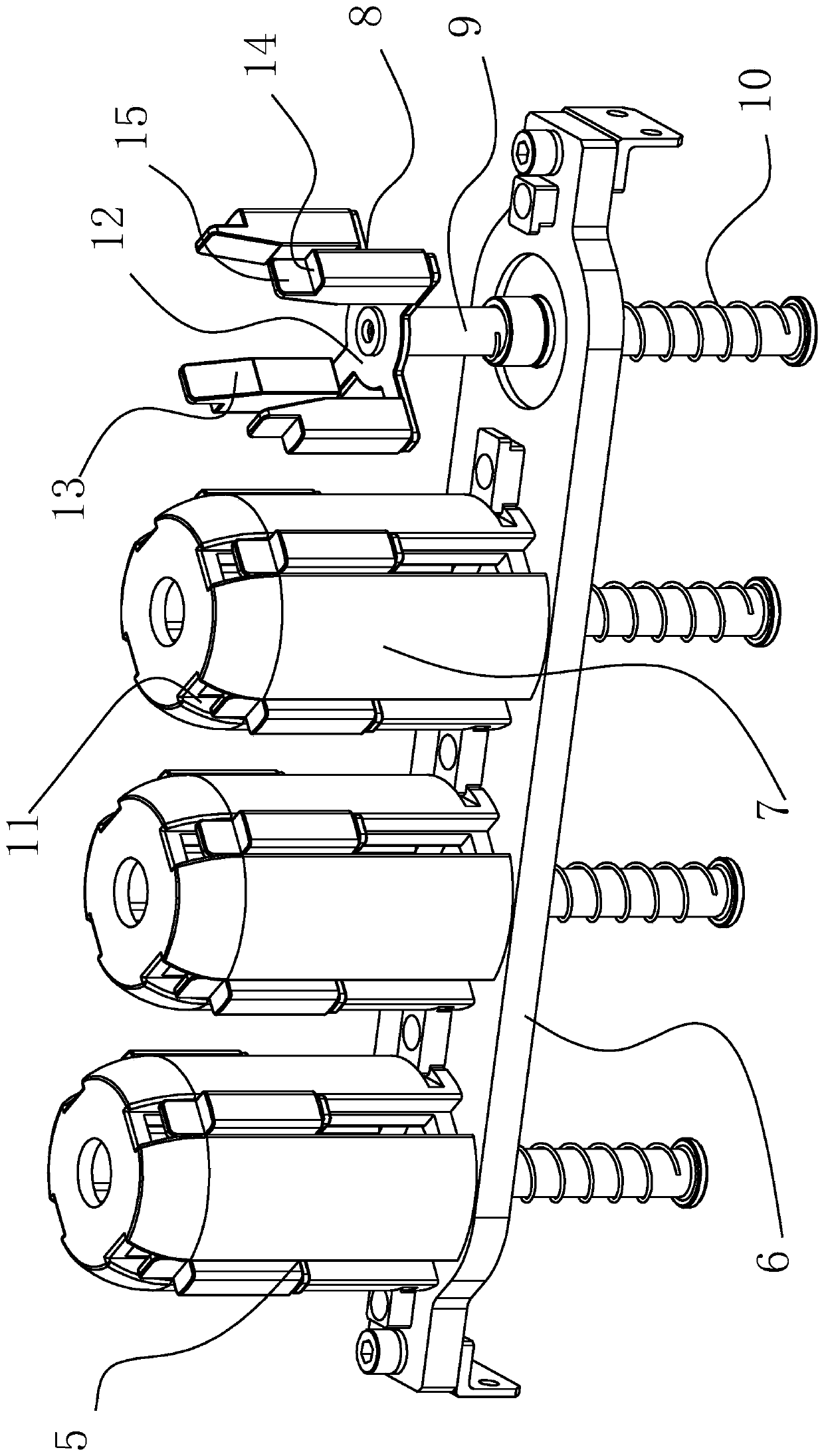

[0019] Combined cup product production equipment includes cup body sealing device, label paper supply device, heat shrink furnace, such as figure 1 , 2 , 3, 4 shown. The multi-cup product production equipment is equipped with a multi-cup conveying path, and the uncut multi-cup product is distributed on the continuous sheet through hot pressing to form a cup body structure and then filled and sealed. The device is used to seal the lid film on the mouth of the cup. The cup body sealing device, label paper supply device, and heat shrink furnace are arranged in sequence on the multi-cup conveying path, that is, uncut multi-cup products first pass through the cup body sealing device, then pass through the label paper supply device, and then pass through the heat shrink furnace. The cup rim structure on the uncut joint cup product is connected as a whole, and the cup body is distributed in a matrix.

[0020] The label paper supply device includes a push-out label component 1 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com