Portable operation and maintenance crane structure for offshore wind power base

A technology for offshore wind power and offshore wind turbines, applied to cranes, etc., can solve the problems of high maintenance cost, small coverage area, and long time-consuming of wind turbines, and achieve high maintenance costs, convenient assembly and disassembly, and large lifting weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

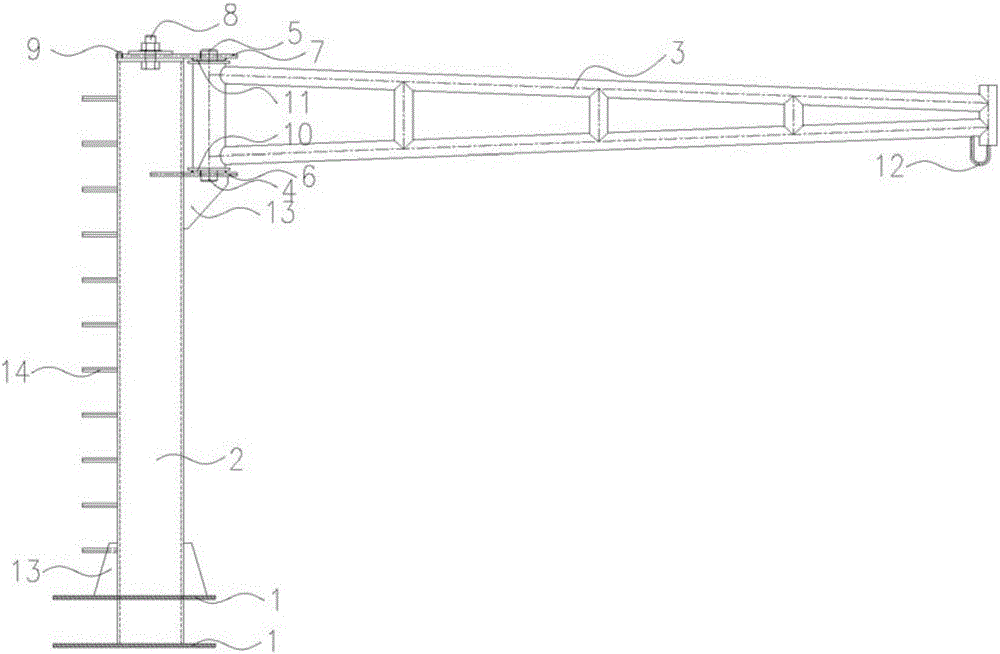

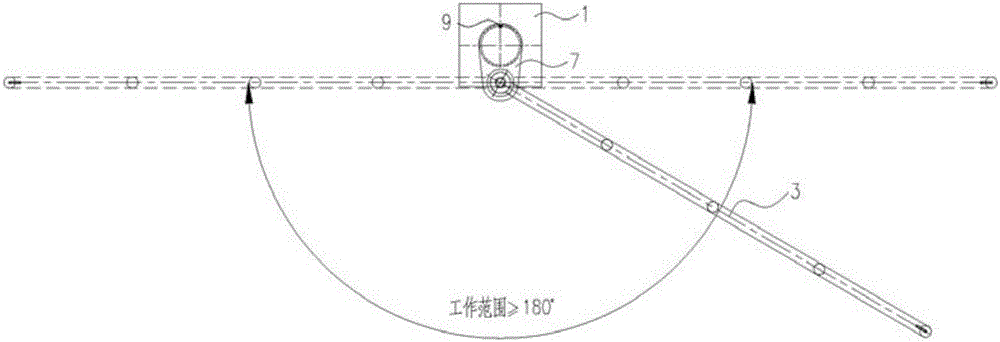

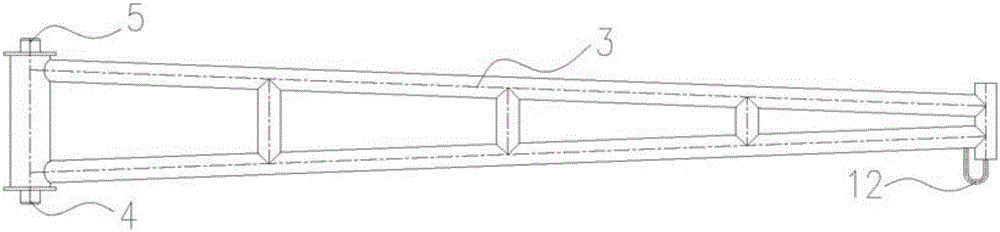

[0027] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , this embodiment includes a crane main cylinder 2 and a truss-type boom 3, the lower end of the crane main cylinder 2 is fixedly connected to the offshore wind turbine platform through a fixed connection support 1, and the upper end of the crane main cylinder 2 is provided with an upper fixing plate 7 and the lower support plate 6, the front end of the truss type boom 3 is provided with a fixed hook 12, and the rear end is provided with an upper connecting shaft 5 and a lower connecting shaft 4; the upper connecting shaft 5 is movably connected with the upper fixed plate 7 and the lower connection The shaft 4 is movably connected with the lower support plate 6 to form a rotating connection structure in which the truss boom 3 surrounds the main cylinder 2 of the crane, so that the movable range of the truss boom 3 is greater than 180 degrees; A number of foot nails are set down to form a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com