Hydraulic lifting jack

A hydraulic lifting and jacking technology, which is applied in the direction of lifting devices, etc., can solve the problems of unsuitable for off-road vehicles, high lifting height, and limited lifting height of jacks, etc., and achieve the effect of convenient operation, strong adaptability, and improved lifting height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

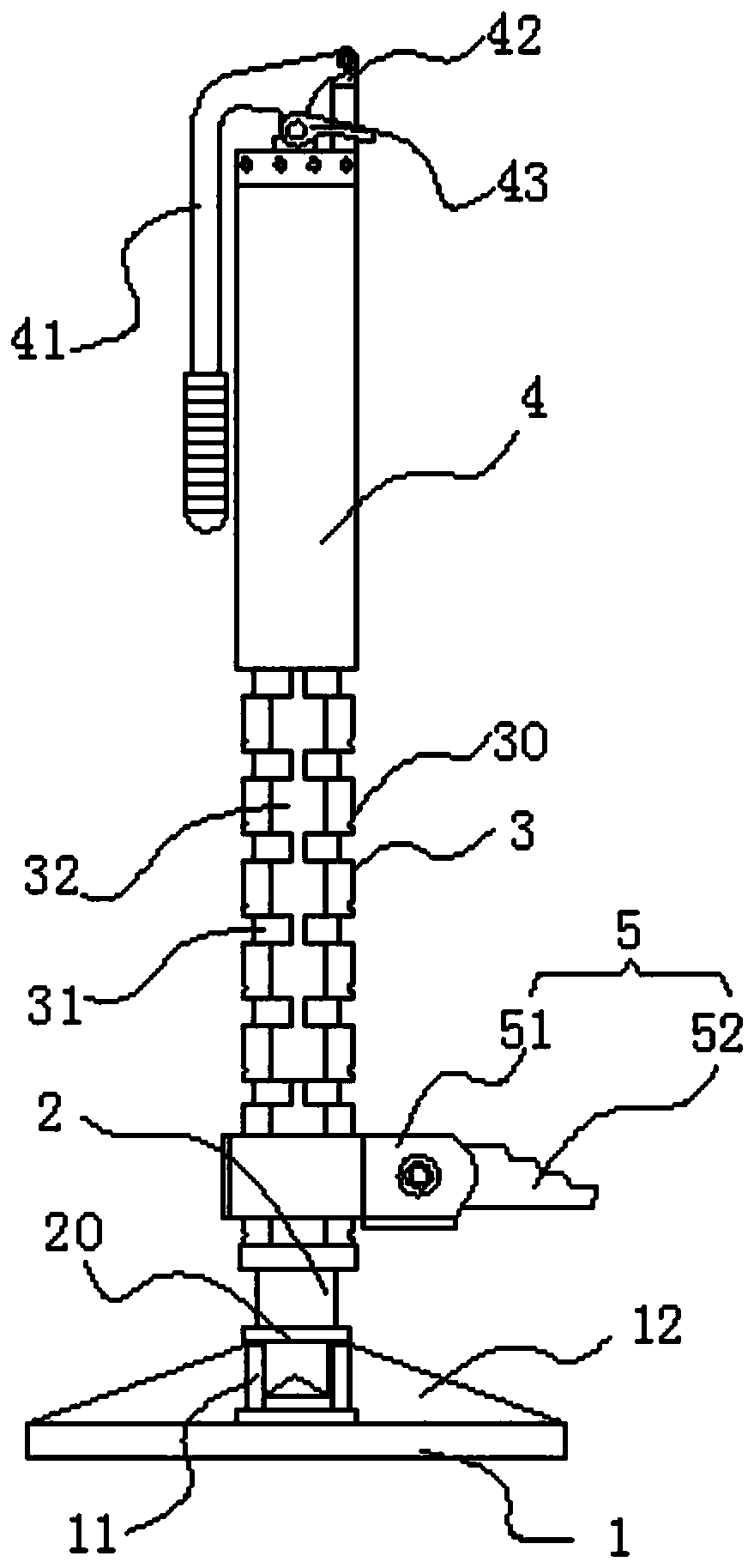

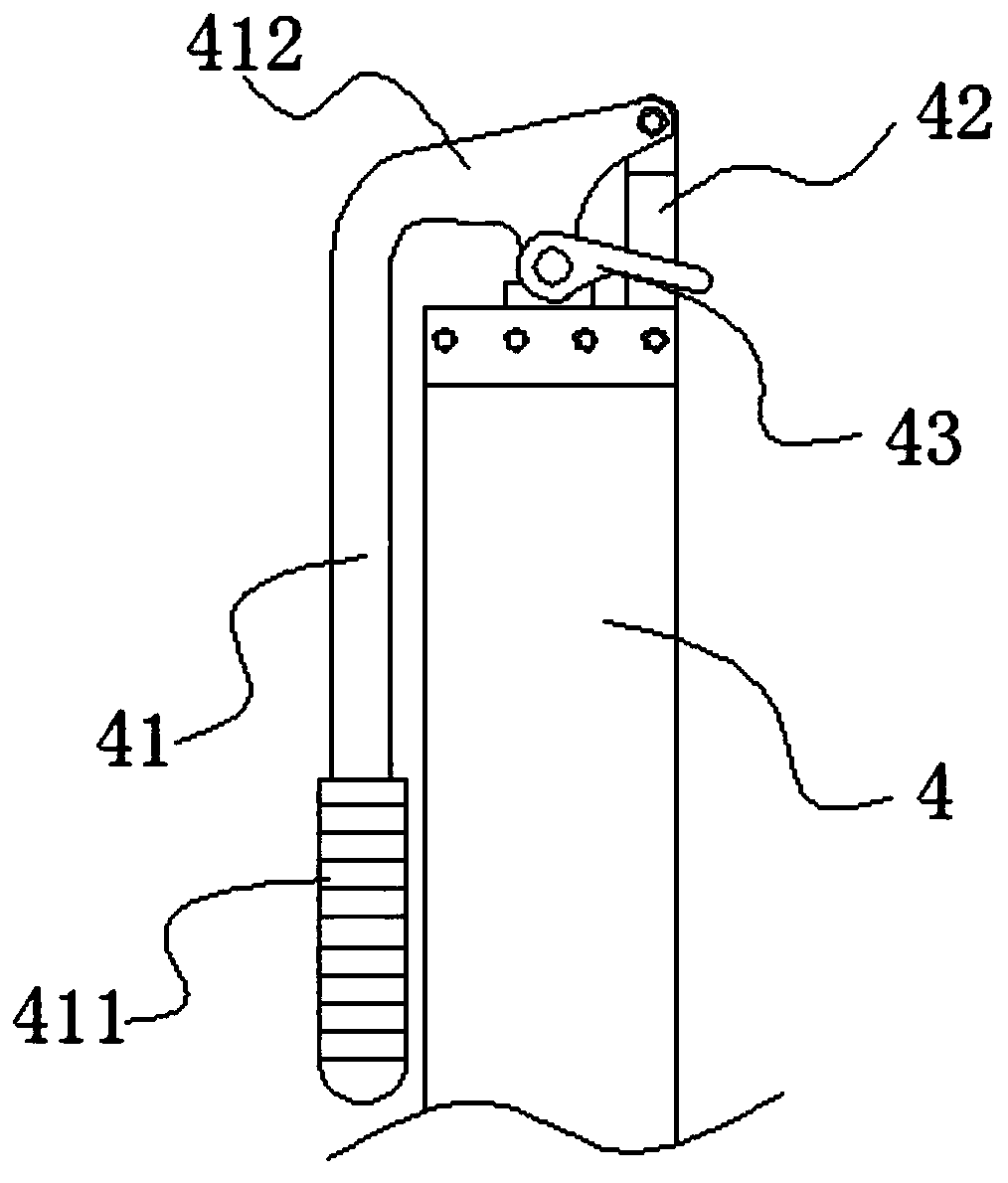

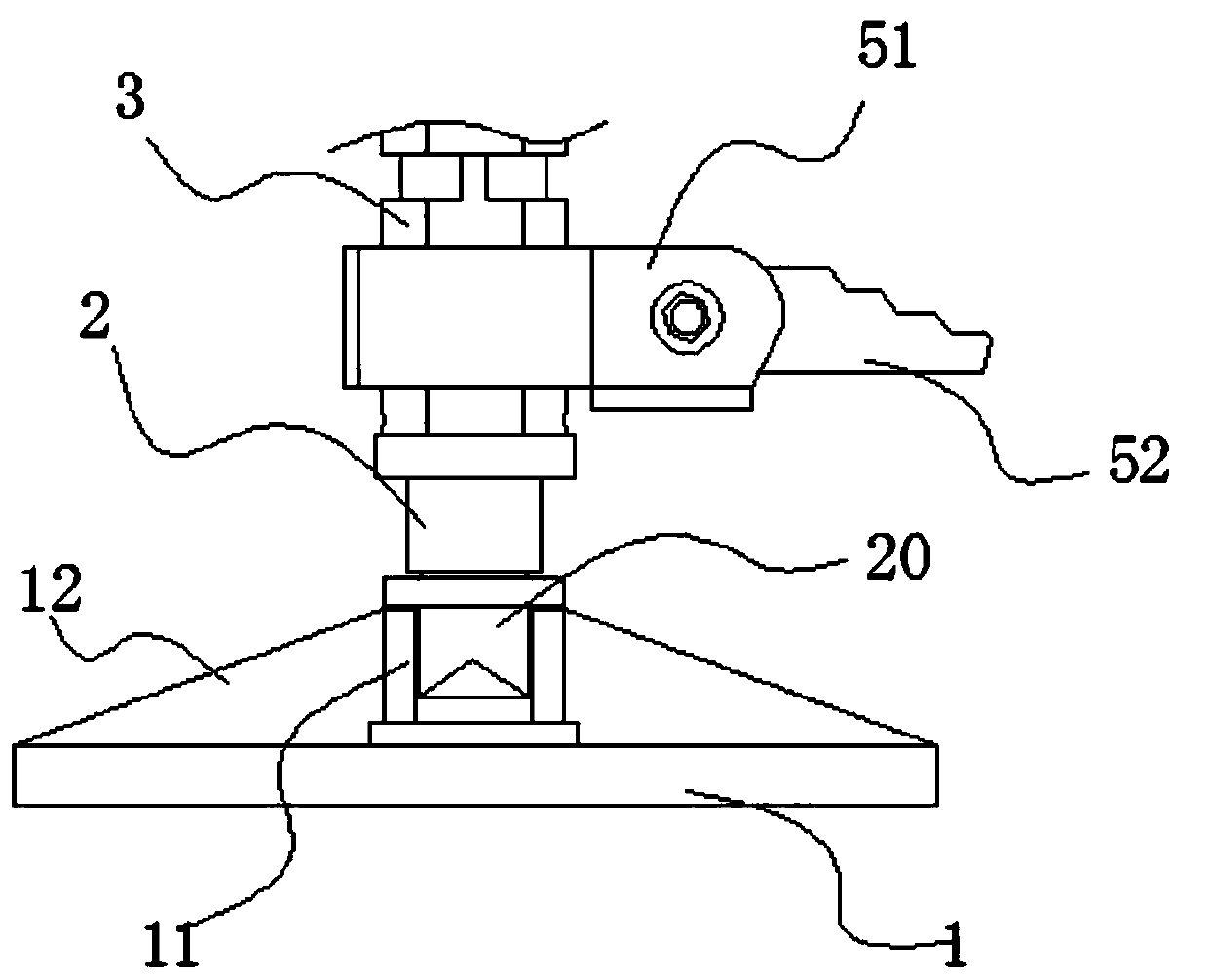

[0020] refer to Figure 1 to Figure 7 A hydraulic lifting jack of the present invention comprises a base 1, a lower cavity tube 2, an outer casing 3, a hydraulic cylinder 4, and a lifting assembly 5 sleeved on the outer casing 3 arranged sequentially from bottom to top, and the lower cavity tube 2 The lower end of the lower chamber tube 2 is connected to the base 1, the upper end of the lower cavity pipe 2 runs through the inner cavity of the outer casing 3, and is connected with the piston rod of the hydraulic cylinder 4, and the upper end of the outer casing 3 is threadedly connected with the lower end of the cylinder body of the hydraulic cylinder 4, The top of the hydraulic cylinder 4 is installed with a pressure rod 41 to control the elongation of the lower cavity tube 2, and a plurality of limit ring grooves 31 are spaced apart on the outer sleeve 3 along its axial direction, and the lifting assembly 5 includes a support leg A sleeve 51 and a support body 52, the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com