Perforating gun for horizontal well

A technology for perforating guns and horizontal wells, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve the problem of radial rotation and axial movement of perforating gun bullet holders, and increase the explosion transmission of perforating guns Failure and other problems, to achieve the effect of reducing the chance of gun body bursting, reducing the loss of jet energy, and avoiding the failure of perforation conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] see Figure 4-8 As shown, a perforating gun for horizontal wells includes:

[0034] The gun body 42, the gun body 42 is cylindrical and tubular, the two ends of the gun body 42 are open, and the surface is provided with preset holes 421 corresponding to the positions of the perforating bullets 20, and the first and last sections of the gun body 42 are respectively installed with the gun head and the gun tail,

[0035] The bullet rack 43, the two ends of the bullet rack 43 are fixed in the gun body 42 through the positioning ring 41, and the center line of the bullet rack 43 and the center line of the gun body 42 are overlapped and arranged, and the perforating charges 20 are discharged on the bullet rack 43,

[0036] The detonator is located at the gun head of the gun body 42, and the detonator is connected to the detonating cord 50,

[0037] The positioning ring 41 includes a ring body 411 , a ring hole 412 is formed at the center of the ring body 411 , a ring groove ...

Embodiment 2

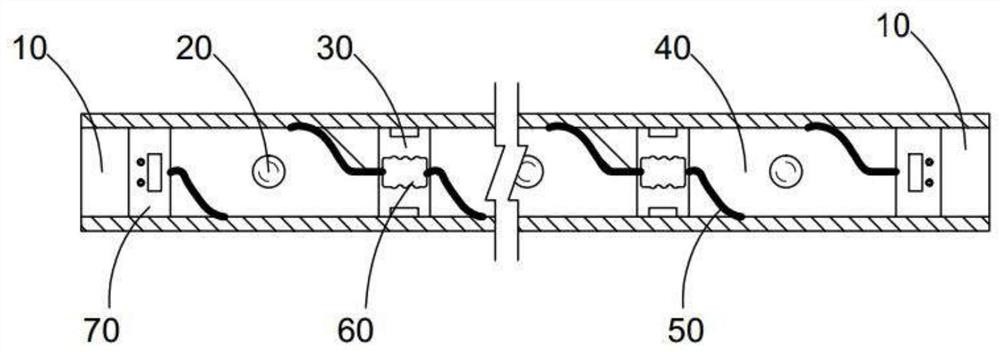

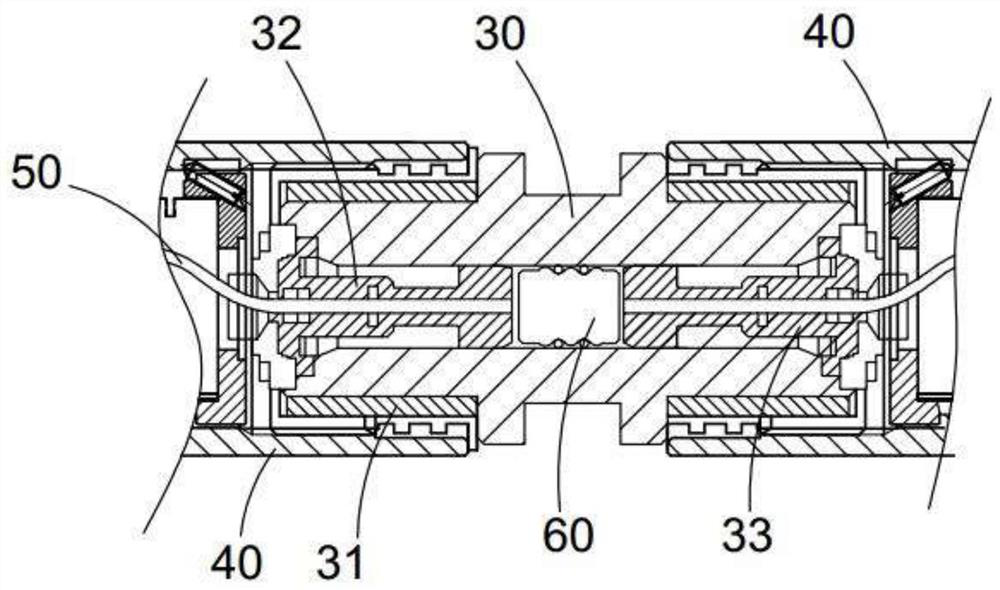

[0043] see Figure 1-4 As shown, the perforating guns 40 are connected by the joint piece 30, the two ends of the joint piece 30 are respectively connected with the adjacent ends of the two perforating guns 40, and the joint is provided with a first sealing sleeve 31, The two adjacent ends of the perforating gun 40 are connected, and the joint piece 30 can be selected from a flexible material to facilitate the positioning of the perforating gun 40 in the casing under the serial connection state. The tightness of the connection between the two perforating guns 40 is improved, and debris can also be prevented from entering the perforating gun 40 .

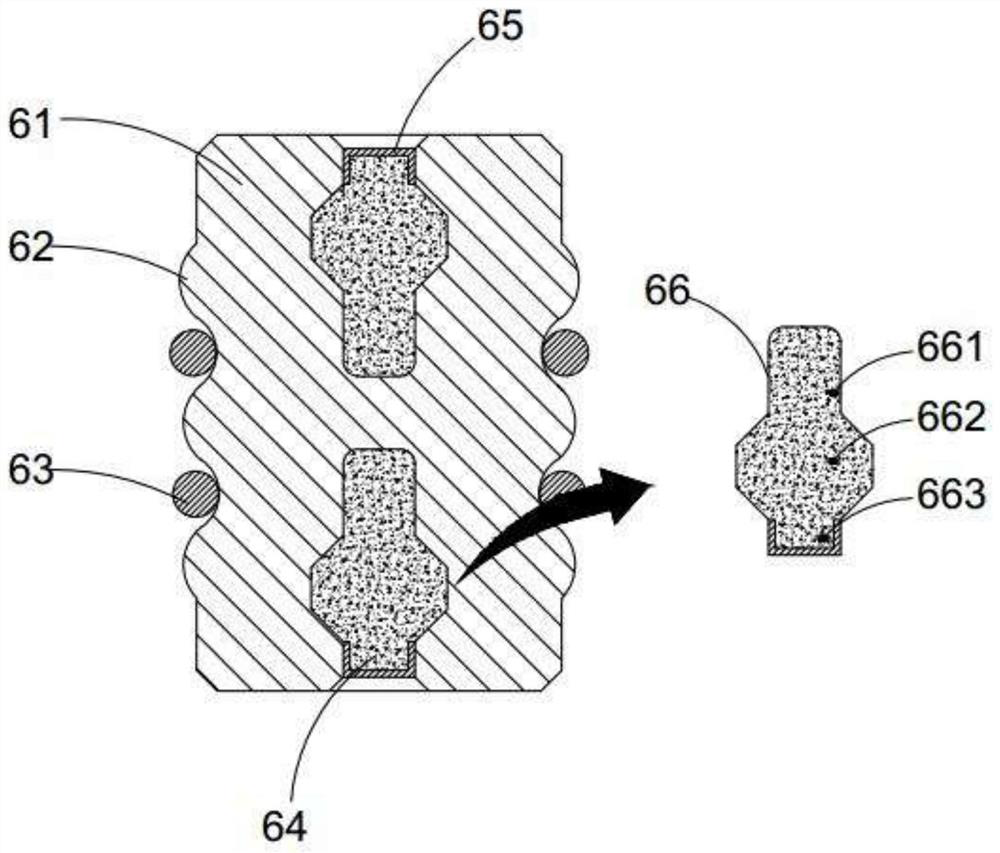

[0044] There is a through hole in the middle of the joint piece 30, and a first booster tube 32 and a second booster tube 33 are respectively installed at both ends of the through hole. The first booster tube 32 and the second booster tube 33 are respectively arranged on the adjacent perforating guns. At the end of 40 , the first bo...

Embodiment 3

[0050] When the perforating gun for horizontal well of the present invention is actually used: install the components on the perforating gun 40 in sequence, such as the bullet rack 43, the positioning ring 41, etc., it is necessary to ensure that the perforating position of the perforating bullet 20 corresponds to the position of the preset hole 421 , after the installation of a single perforating gun is completed, the perforating guns 40 are serially connected in sequence through the joint piece 30 and the first sealing sleeve 31, and the required perforating guns 40 are connected in series according to the perforating needs. The perforating gun 40 used in the present invention The length of the gun body 42 is 1 meter. During the process of connecting the perforating guns 40 in series, it is ensured that the energizing body 61 is arranged in the joint 30, and both ends of the energizing body 61 are connected to the first booster tube 32 and the second booster at the front and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com