Lagging discharge preventing device and method for high-pressure flushing systems in shielding equipment

A technology of equipment warehouse and internal high pressure, applied in mining equipment, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of tunneling mud circulating slag system stagnation, excessive stone particle size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

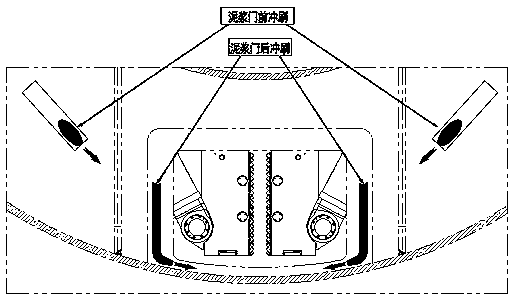

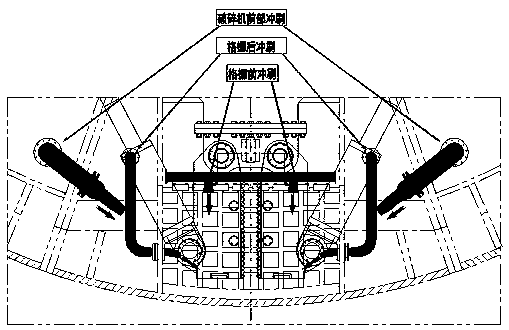

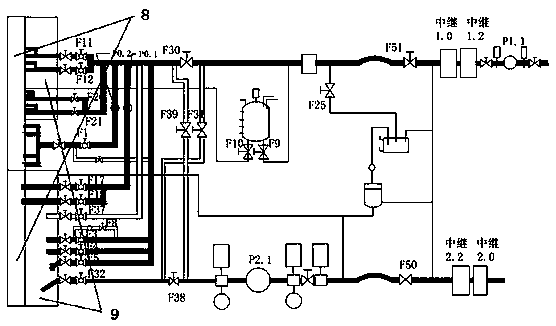

[0046]An anti-sluggish discharge device for the high-pressure flushing system in the shield equipment chamber, see Figure 1 to Figure 8 , the design includes a mud circulation system connected to the reverse flushing branch. The main road of the mud circulation system is equipped with a slurry inlet pump and a slurry discharge pump. The main road is connected to the excavation branch. Scouring branch, scouring branch in grille, reverse flushing branch, cutterhead flushing branch; mud door flushing branch, crusher flushing branch, grille interior flushing branch, reverse flushing branch, cutterhead flushing branch There are corresponding opening and closing valves on the road. The outlet of the mud door scour branch is set at the bottom of the front partition in the shield machine, and the outlet of the crusher scour branch is set at the bottom edge of the rear partition in the shield machine. The outlet of the flushing branch in the grid is set in the middle of the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com