Variable-volume silencer and compressor

A muffler and noise reduction technology, applied in the field of compressors, can solve problems such as airflow buffering that is difficult to impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

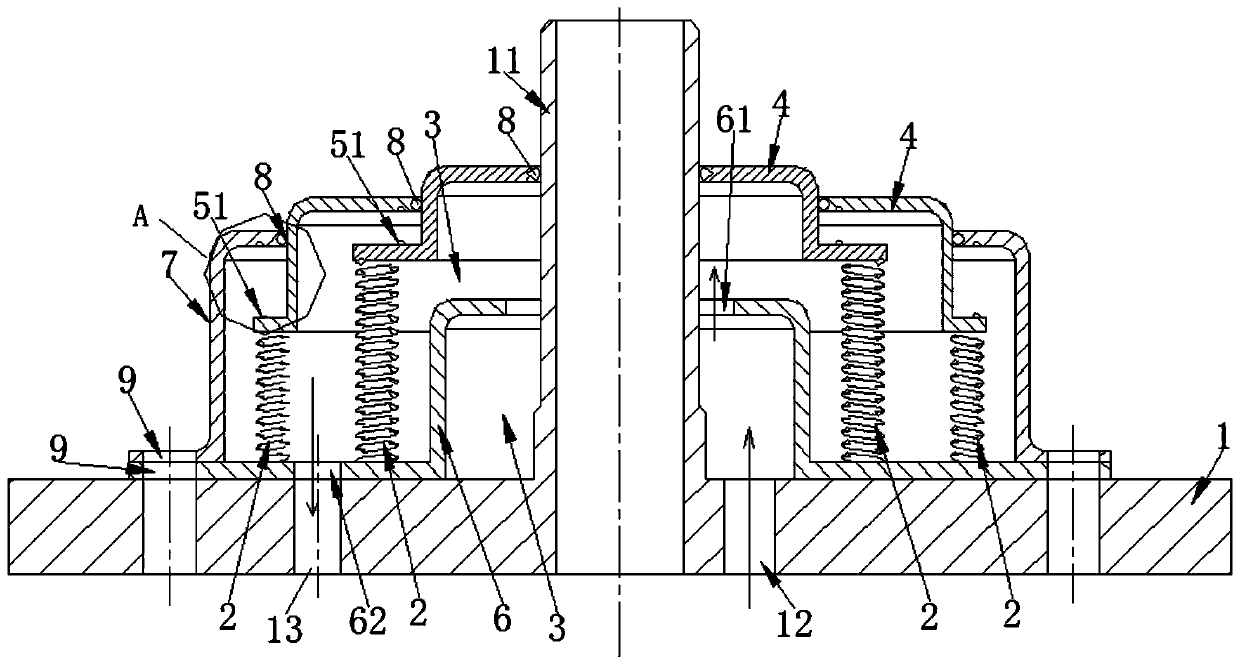

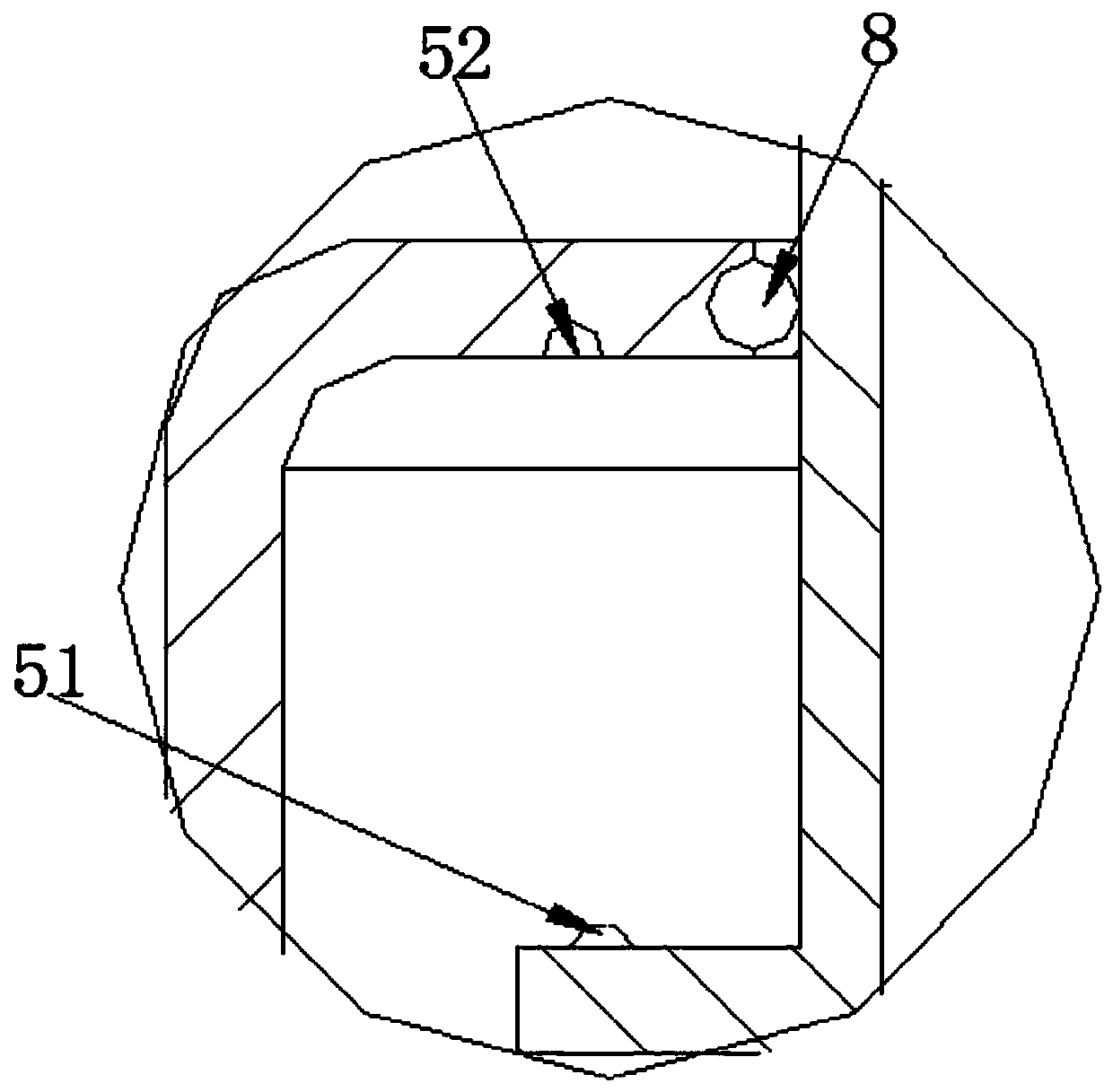

[0040] see Figure 1-Figure 4 , a muffler with variable volume, comprising a movable muffler 4, a muffler fixed part 7 and an inner layer muffler 6; the number of the movable muffler 4 can be two, and the movable muffler 4 is sleeved sequentially from the inside to the outside, The innermost movable muffler 4 is provided with a flange shaft installation hole, and the outermost movable muffler 4 is connected with the muffler fixed part 7 and sleeved in the muffler fixed part 7, each movable muffler The parts 4 are connected with the inner layer muffler 6 through springs; the inner layer muffler 6 is provided with a through hole 61 matched with the flange shaft 11, and the gas entering the inner layer muffler 6 from the flange exhaust inlet 12 It can enter another gas containing chamber 3 through the gap between the inner muffler 6 and the flange shaft 11; the inner muffler 6 is provided with an air outlet 62 communicating with the flange exhaust outlet 13 and the gas accommodat...

Embodiment 2

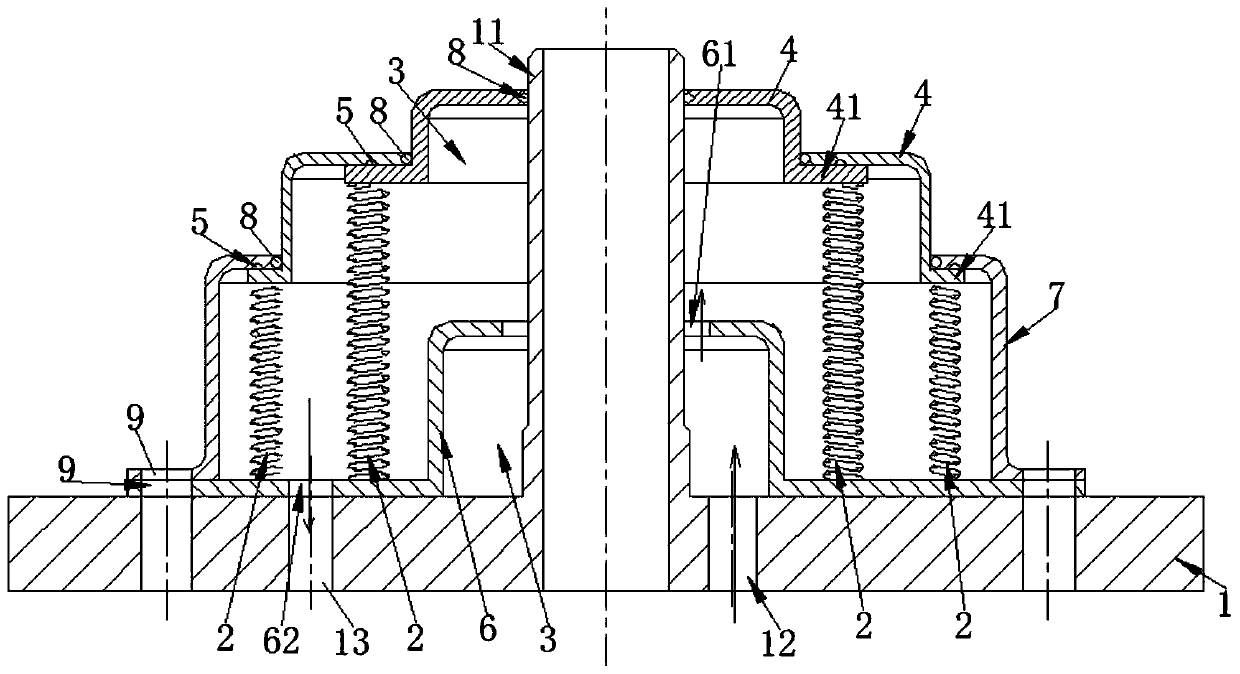

[0042] see Figure 5 , a muffler with variable volume, including a movable muffler 4 and a muffler fixed part 7; the number of the movable muffler 4 is one, the movable muffler 4 is connected to the flange 1 through a spring, and the muffler fixed part 7 is sleeved Outside the movable muffler part 4, a flange mounting hole 9 is provided on the muffler fixed part 7; between the movable muffler part 4 and the flange shaft 11, and between the movable muffler part 4 and the muffler fixed part 7 are used to reduce friction The contact structure is connected; the end of the movable muffler 4 that is far away from the end face of the flange 1 extends outward in the horizontal direction to form a limiting section 4 for limiting itself from the muffler fixing part 7, between the limiting section 4 and the muffler fixing part 7 There is a vibration damping structure 5 .

Embodiment 3

[0044] see Figure 6 , a muffler with variable volume, different from Embodiment 2, the number of movable mufflers 4 is two, and the movable mufflers 4 are sleeved sequentially from the inside to the outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com