Ash removal rapping device

A rapping device and ash cleaning technology, applied in the directions of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient and complicated adjustment, and achieve the effect of improving practicability and improving the convenience of adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

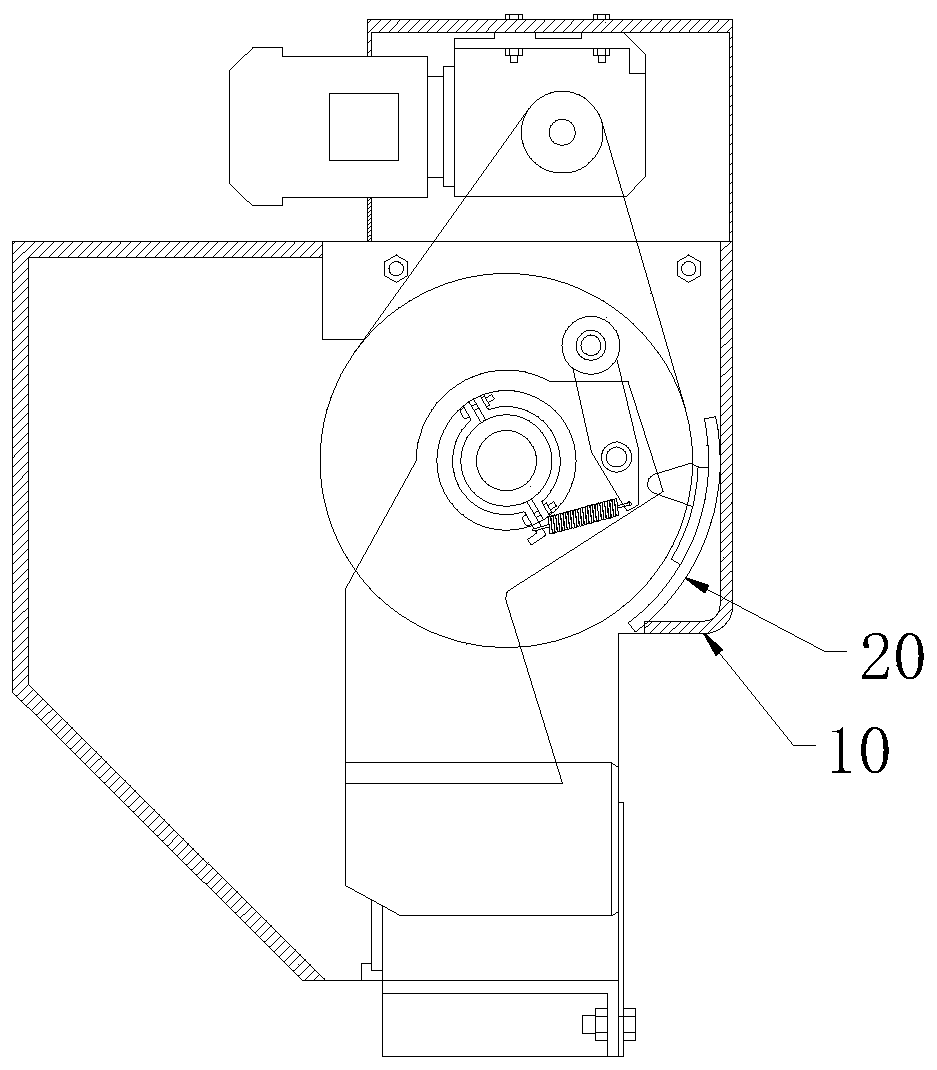

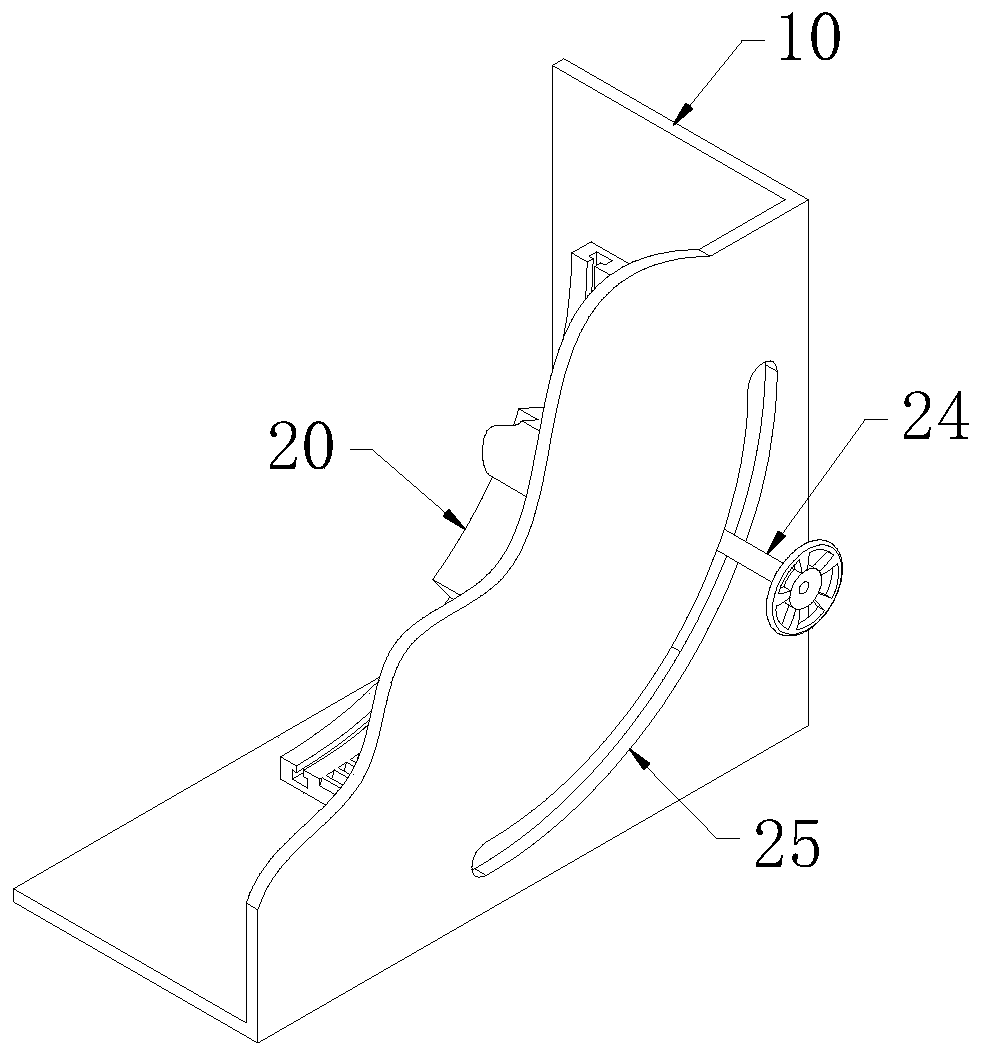

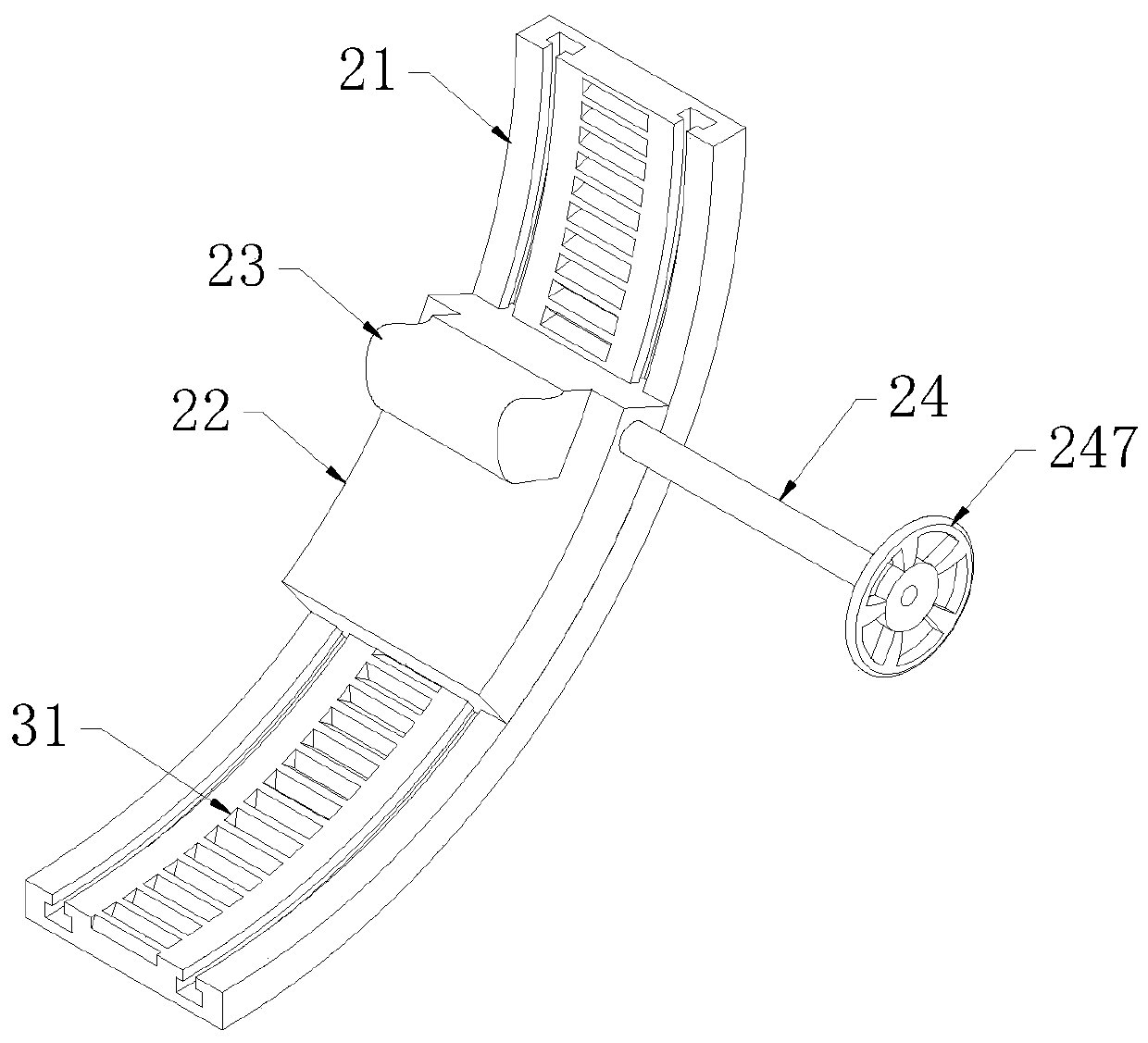

[0019] Such as Figure 1~3 As shown, a dust cleaning and rapping device includes a housing 10, a drop hammer assembly 20 is installed in the housing 10, and the drop hammer assembly 20 includes a fixed track 21, an adjustment track 22, a push block 23 and an adjustment rod 24. The fixed rail 21 is fixedly installed inside the housing 10, the adjustment rail 22 is slidably arranged on the fixed rail 21, the push block 23 is fixedly arranged on the adjustment rail 22, and one end of the adjustment rod 24 is connected with the adjustment The track 22 is connected, and the other end of the adjusting rod 24 extends to the outside of the side wall adjacent to the installation surface on the housing 10 to control and adjust the position of the adjusting track 22. The locking structure controlled by the adjusting rod 24 , the side wall of the housing 10 is provided with a chute 25 for adjusting the adjusting rod 24 that matches the adjusting sliding track of the adjusting track 22 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com