A picosecond fiber seed laser source structure

A technology of laser source and seed, applied in the structure/shape of active medium, laser, phonon exciter, etc., can solve the problem of short working life of single point of saturable absorption mirror, achieve simple structure, reduce production cost, pulse signal stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

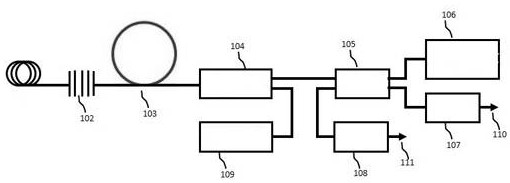

[0030] A picosecond fiber seed laser source structure described in Example 1, such as figure 1 As shown, it includes a resonant cavity of laser line type. The resonant cavity includes a semiconductor saturable absorption mirror 106, a beam splitter 105, a wavelength division synthesizer 104, a gain fiber 103, and a fiber grating 102; The pump laser diode 109 that couples the pump laser light into the resonator is connected; the optical splitter is connected with a fiber isolator 108 and a polarization-maintaining fiber isolator 107 respectively, and the polarization-maintaining fiber isolator is connected with a forward output as a seed source output signal port The port 110 is connected to the optical fiber isolator with a backward output port 111 for monitoring and system internal processing signal output.

[0031] The pump laser diode generates continuous 976nm pump laser light, which is coupled into the resonant cavity through a wavelength division synthesizer. At the beg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap