A multifunctional pipette gun

A pipette gun and multi-functional technology, applied in the field of pipette guns, can solve the problems of poor applicability, inconvenient replacement, lack of counting function and range selection function, etc., and achieve the effect of strong applicability and avoiding operational mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

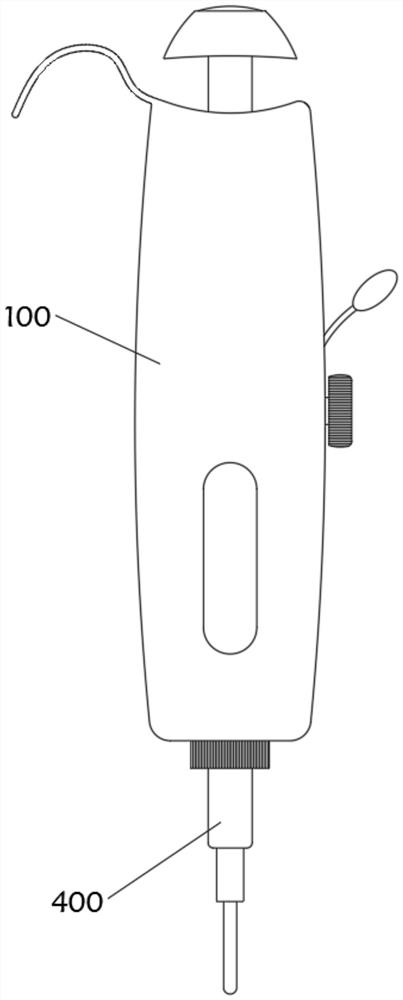

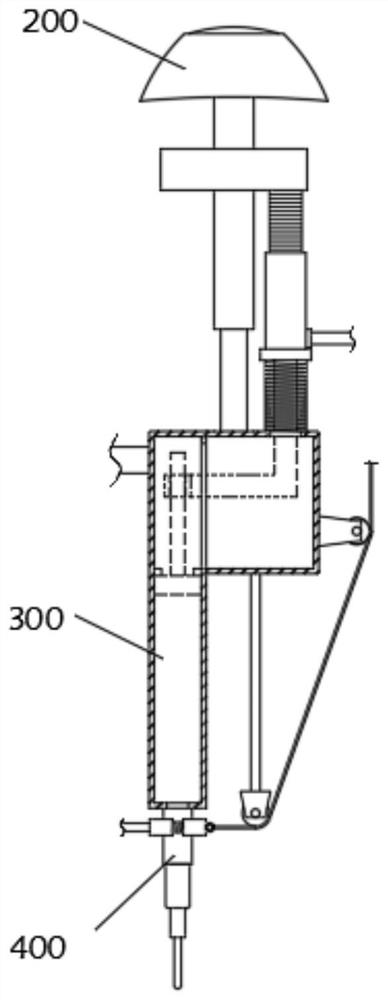

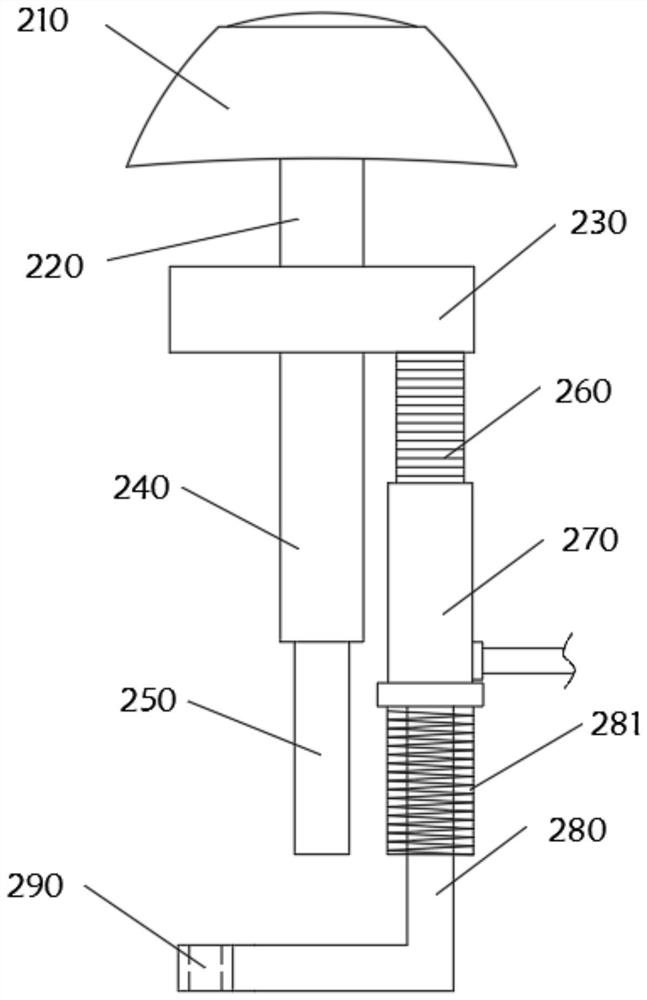

[0059] The invention provides a multifunctional pipetting gun, such as Figure 1-Figure 16 As shown, it at least includes: a housing 100, a pressing mechanism 200, a liquid suction mechanism 300 and a liquid suction head 400. The housing 100 is a hollow structure that penetrates up and down, so that the pressing mechanism 200, the liquid suction mechanism 300 and the liquid suction head are placed in the housing 100. The head 400 and the pressing mechanism 200 are located inside the housing 100. The pressing mechanism 200 includes a pressing head 210. The pressing head 210 has an upwardly protruding arc structure, which is convenient for improving the comfort of the pressing head 210 when pressing. The pressing head 210 is located on the top of the housing 100. Make the pressing head 210 have a certain distance to press downwards, the bottom of the pressing head 210 is equipped with a pressing bar 220, the bottom of the pressing bar 220 is vertically equipped with a pressing pl...

Embodiment 2

[0071] see Figure 17 As shown, an externally threaded tube 120 is installed on the bottom of the housing 100, and a pipetting plate 600 is provided at the bottom of the housing 100. The inside of the pipetting plate 600 is a hollow structure, and the top of the pipetting plate 600 is provided with an internal thread head that communicates with the inside. 610, realizing the connection between the internal thread head 610 and the pipetting plate 600, the internal thread head 610 and the external thread pipe 120 are threaded, which is convenient for the disassembly and assembly of the pipetting plate 600 and the shell 100, suitable for different needs, the bottom of the pipetting plate 600 is set Several pipette tips 620 communicated with the inside.

Embodiment 3

[0073] see Figure 18-Figure 21 As shown, a counter 130 for counting is installed on the outer wall of the casing 100 .

[0074] In this embodiment, the counter 130 includes a 74ls163 preset counter, a CD4511 decoder and a display digital tube.

[0075]Among them, 74ls163 is a 4-bit binary synchronous preset counter. When port 16 is connected to high level and port 8 is grounded, it works normally. When ports 1, 7, 9, and 10 are connected to high level, the chip counts from 11, 12, 13, 14 port output. When the No. 1 port is low level, the output is 0, and the No. 2 port is connected to the pulse signal. Each time a pulse signal is connected, the count is counted. The single-pole double-throw switch is connected to LOAD to set zero, and it is counted when it is connected to a high voltage. Set to zero at ground voltage.

[0076] Among them, CD4511 is a 7-segment decoder for BCD. When VDD, BI, LI are connected to high level, VSS, LE / STROBE are connected to ground, D, C, B, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com