Clothes washing equipment and detergent feeding control method and device for clothes washing equipment

A detergent injection and laundry washing technology, which is applied to the detergent injection control of laundry washing equipment, and in the field of laundry washing equipment, can solve the problems of excessive detergent injection, waste of water resources, and inability to add detergent, so as to avoid environmental pollution. Pollution, effect of meeting wash and rinse requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a detergent dispensing control method for laundry washing equipment.

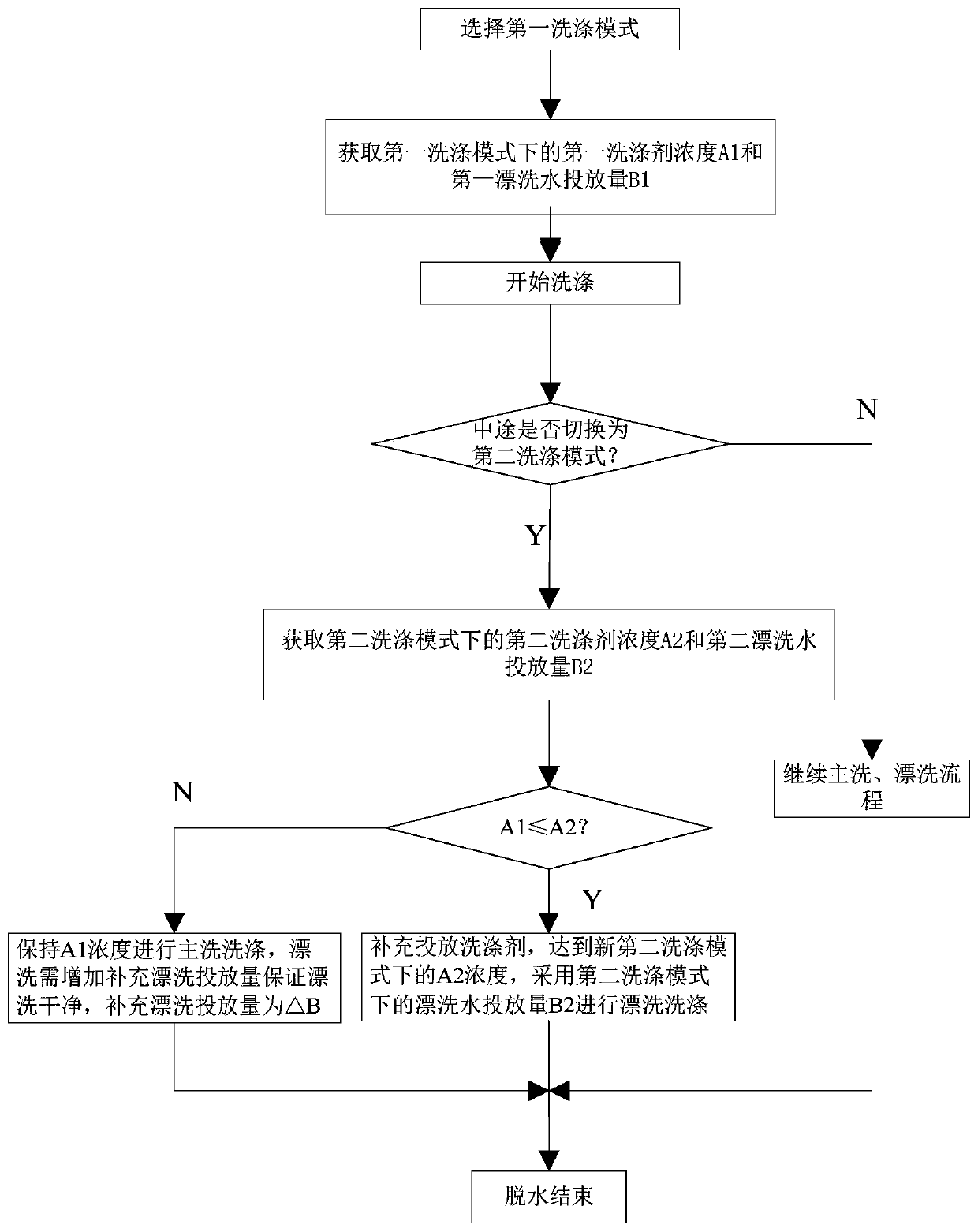

[0048] figure 1 It is a flow chart of a detergent dispensing control method for laundry washing equipment according to an embodiment of the present application, which includes the following steps:

[0049] Step 1: Obtain the first detergent concentration A of the laundry washing device in the first washing mode 1 And the first rinse water dosage B 1 .

[0050] Before the clothes washing device washes the clothes, the weight of the clothes is obtained. Preferably, the laundry in the laundry washing device is weighed by the weighing device of the laundry washing device to obtain the weight of the laundry, and the weight of the laundry is combined with the selected first washing mode to determine that the laundry washing device is working The first detergent concentration A in the first washing mode 1 And the first rinse water dosage B 1 . Optionally, by obtaining a preset formula in...

Embodiment 2

[0067] This embodiment provides a detergent dispensing control device for laundry washing equipment. It should be noted that the detergent dispensing control device of Embodiment 2 can be used to execute the detergent dispensing control method of Embodiment 1 of the present invention.

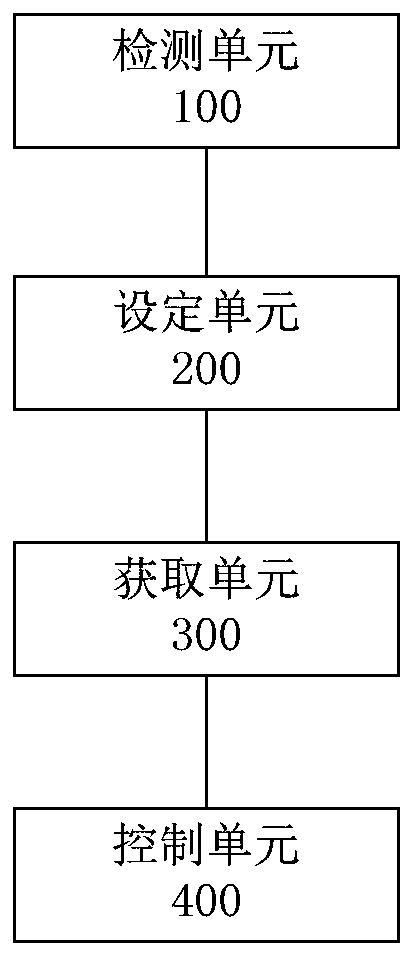

[0068] figure 2 It is a schematic diagram of a detergent dispensing control device for laundry washing equipment according to an embodiment of the present invention. Such as figure 2 As shown, the detergent dispensing control device includes a detection unit 100, a setting unit 200, an acquisition unit 300, and a control unit 400.

[0069] The detection unit 100 is used to detect the weight of clothes.

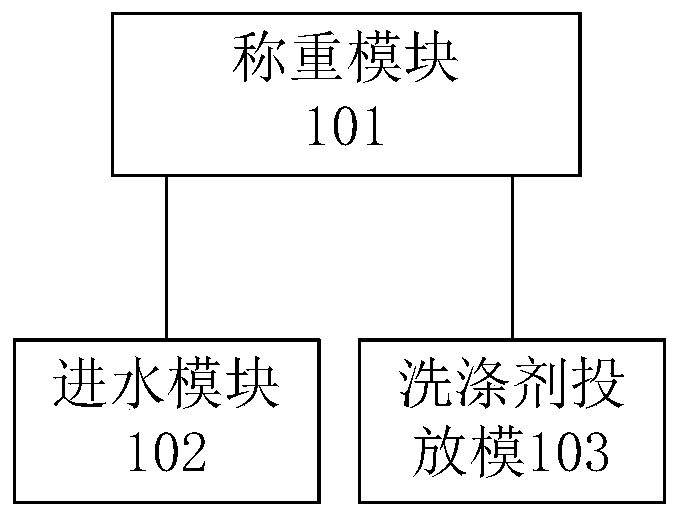

[0070] Such as image 3 As shown, the detection unit 100 includes a weighing module 101, a water inlet module 102, and a detergent injection module 103. Among them, the weighing module 101 is used to weigh the clothes in the laundry washing device to obtain the weight of the clothes; the water int...

Embodiment 3

[0084] This embodiment provides a laundry washing device. The laundry washing equipment includes the detergent dispensing control device provided in Embodiment 2 of the present application. The laundry washing equipment includes, but is not limited to, various types of washing machines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com