Mulching film collector

A recycling machine, plastic film technology, applied in the direction of collectors, agricultural machinery and implements, applications, etc., can solve the problem of residual film falling, recycling cost impact, affecting plastic film recycling efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

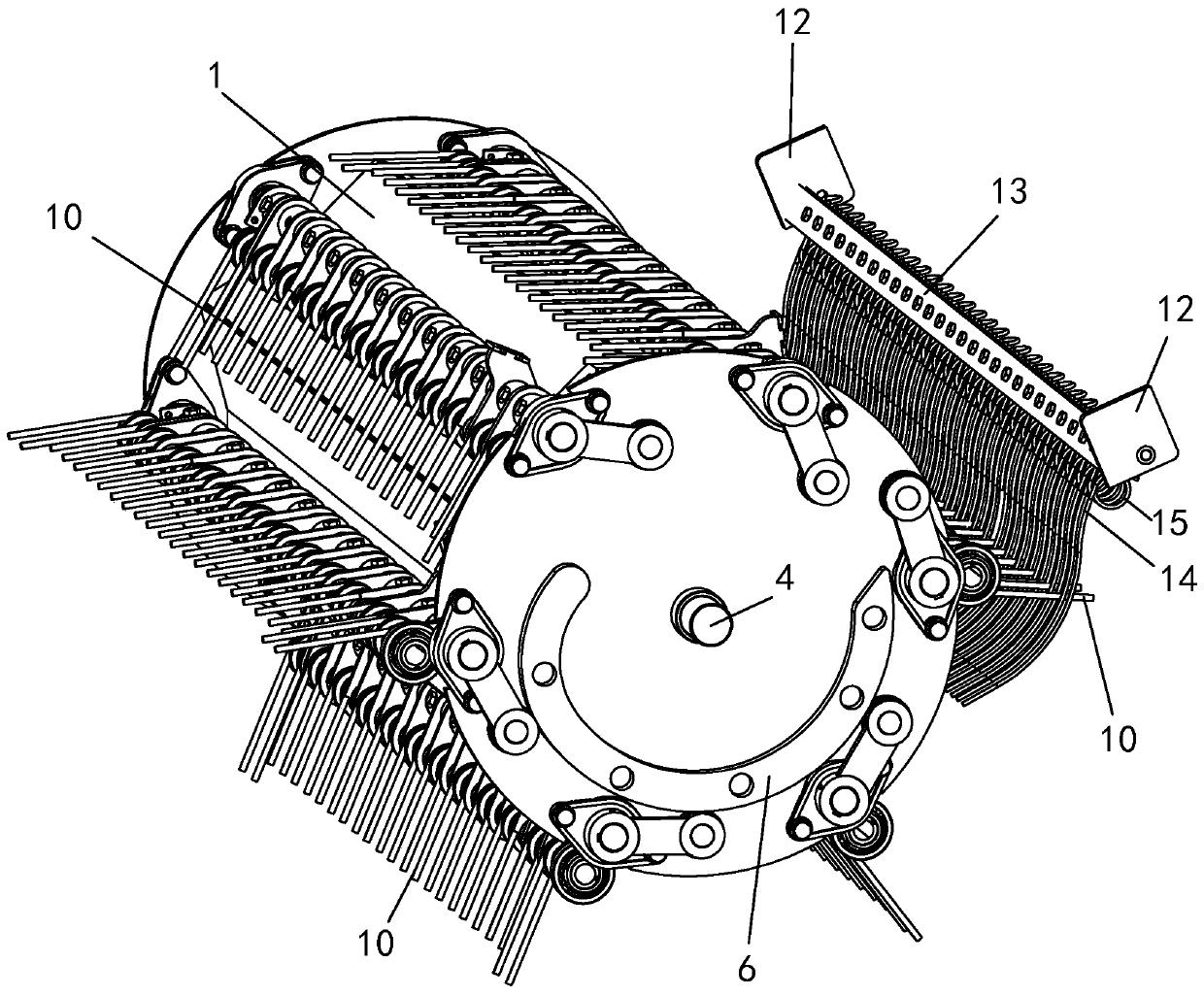

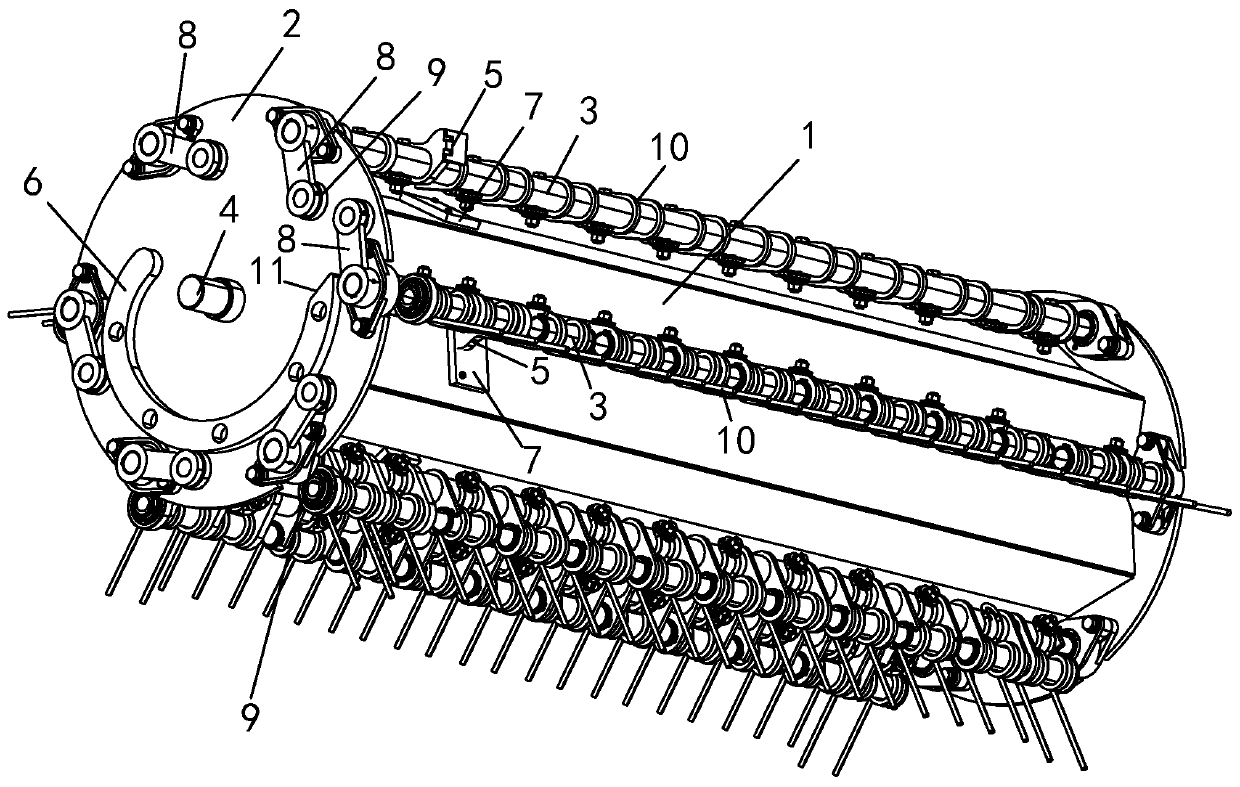

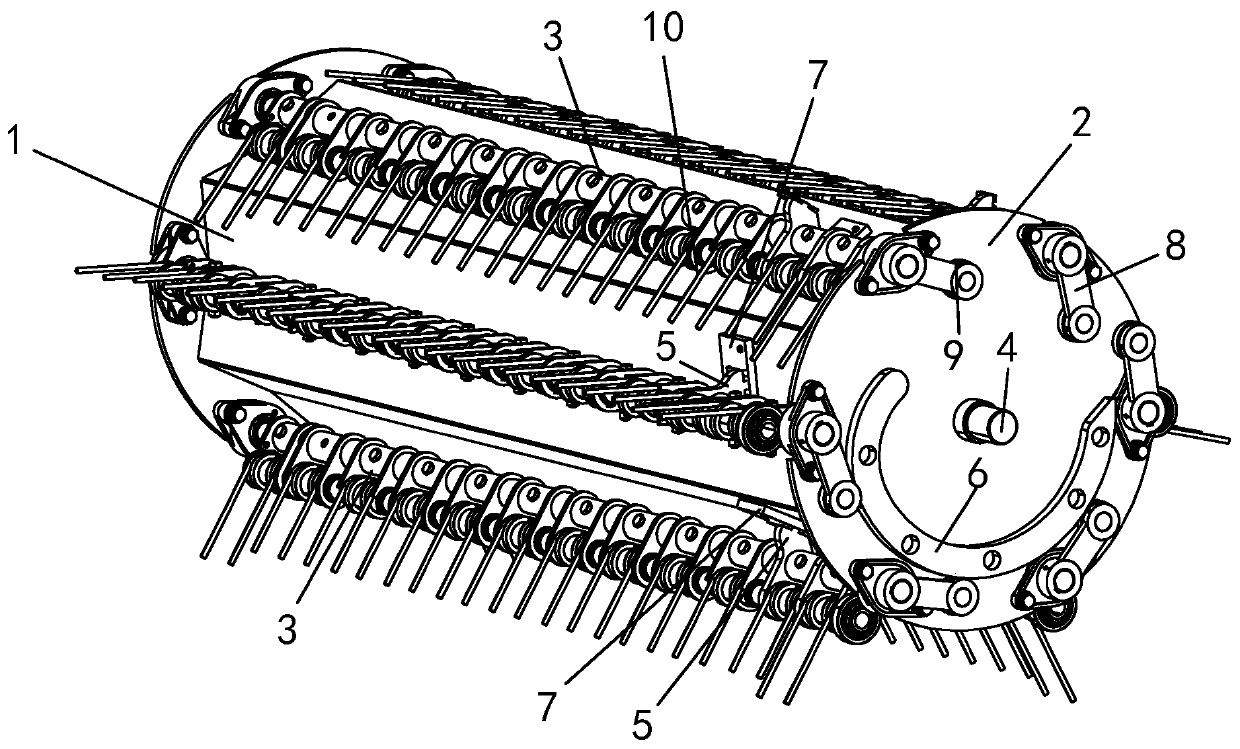

[0025] see Figure 1-3 , what this embodiment provides is a mulch recovery machine, including torsion spring 10, vehicle frame, roller 1, end plate 2, spring shaft 3, rotating shaft 4, first stopper 5, second stopper, baffle 6. Press plate 13, sieve rod and multiple sieve bars 14.

[0026] The baffle 6 is fixed on the vehicle frame, and the rotating shaft 4 is rotatably arranged on the vehicle frame, so that the axis of the rotating shaft 4 and the baffle 6 move synchronously, so that the axis of the rotating shaft 4 and the baffle 6 are relatively stationary. The shape of the drum 1 is roughly a positive prism, and the rotating shaft 4 runs through the center of the drum 1 and is fixed with the drum 1 so that the drum 1 rotates around the axis of the rotating shaft 4 . The end plates 2 are two circular plates, and the two end plates 2 are fixed to the two end surfaces of the drum 1 respectively, and the drum 1 drives the end plates 2 to rotate around the axis of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com