Mechanism for cleaning needle roller of winnowing machine

A technology of air separator and needle roller, which is applied in the field of air separator needle roller cleaning mechanism, which can solve the problems that the surface of the needle roller cannot be cleaned well, and the materials and sundries on the surface of the needle roller cannot be cleaned, so as to achieve good Cleaning, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

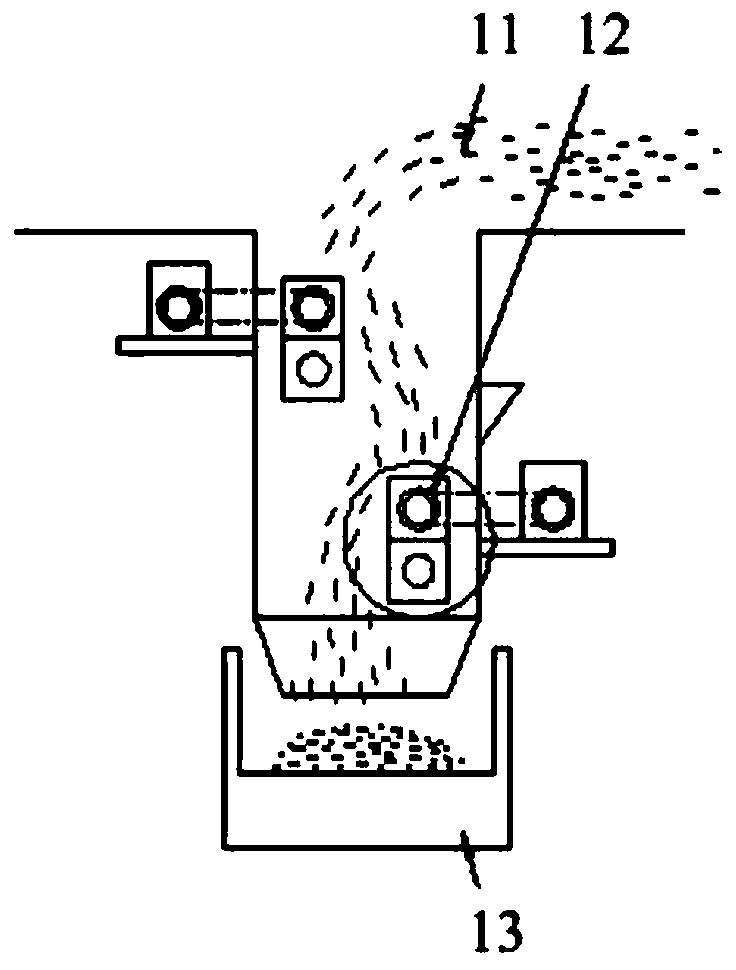

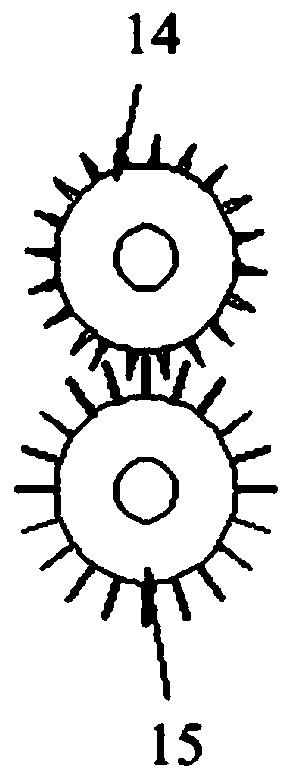

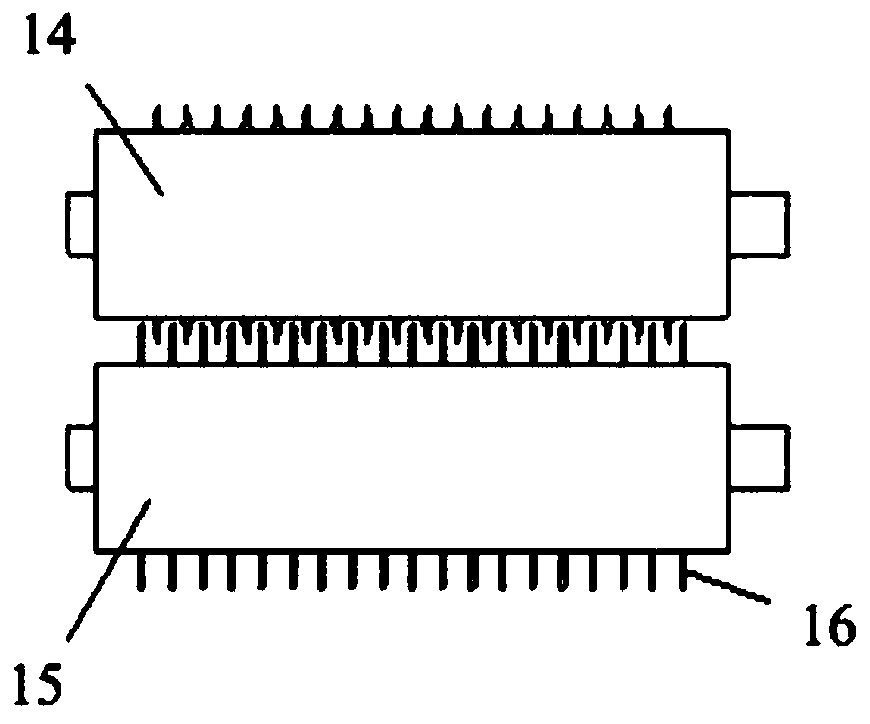

[0037] like Figure 4 to Figure 11 As shown, the embodiment of the present invention provides a needle roller cleaning mechanism for air separator, which includes a scraper shaft 61 arranged below the needle roller, a scraper 31, a fixed frame 51, and a rotary drive for driving the scraper shaft 61 to rotate. mechanism, the scraper shaft is arranged parallel to the needle roller 21, a plurality of scraper blades 31 are arranged in the axial direction of the scraper shaft, and the tip portion 32 of the scraper blade is close to the surface of the needle roller 21; The first end of the scraper shaft passes through the first connecting hole of the fixed frame 51, the second end of the scraper shaft passes through the second connecting hole of the fixed frame 51, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com