Novel automobile C-pillar door frame sealing structure

A sealing structure and automobile technology, applied in sealing devices, engine sealing, vehicle parts, etc., can solve the problems of high and low step difference, affecting the appearance, etc., achieve smooth connection, strengthen the fixing effect, and increase the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Nine, the following specific embodiments further illustrate the present invention.

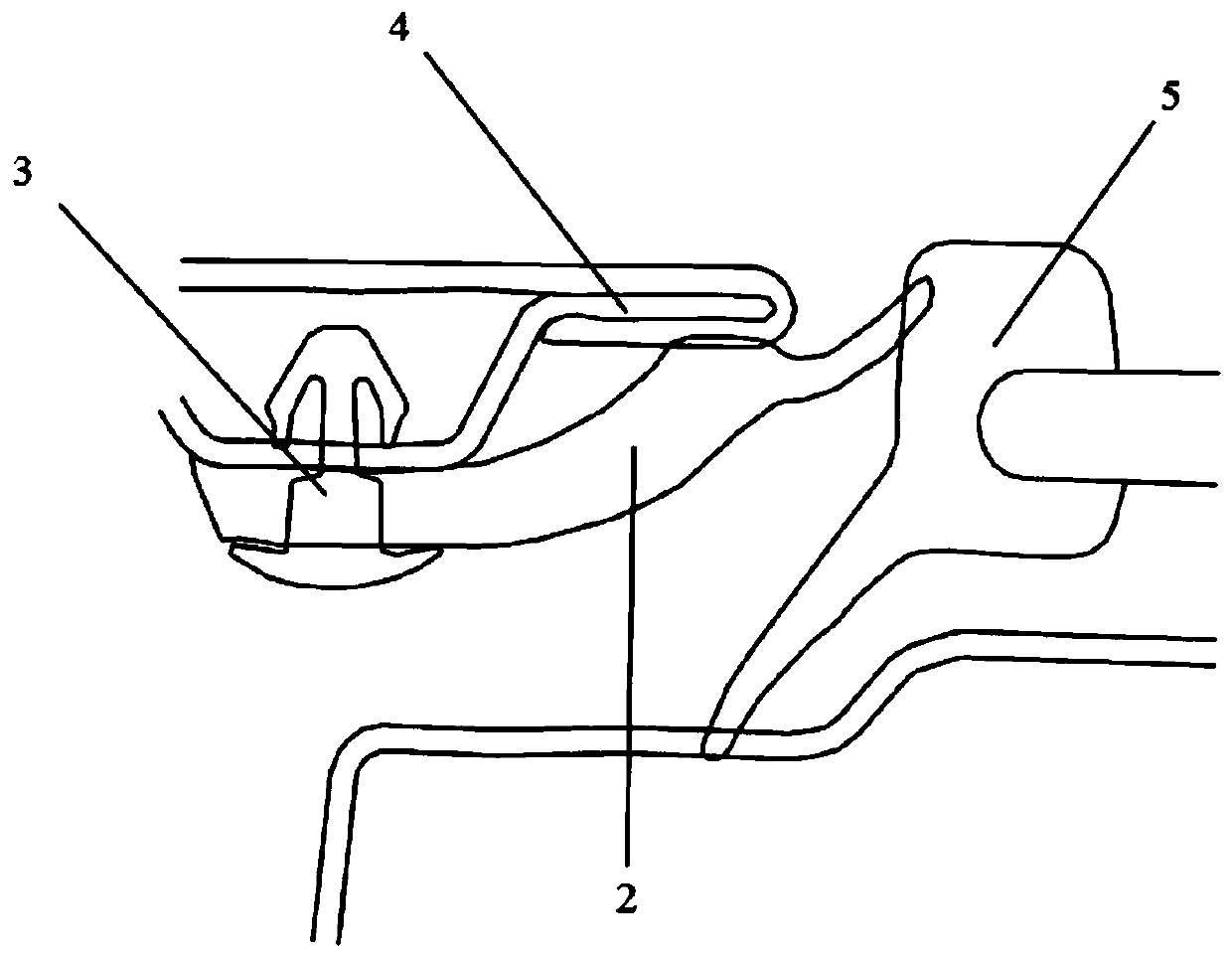

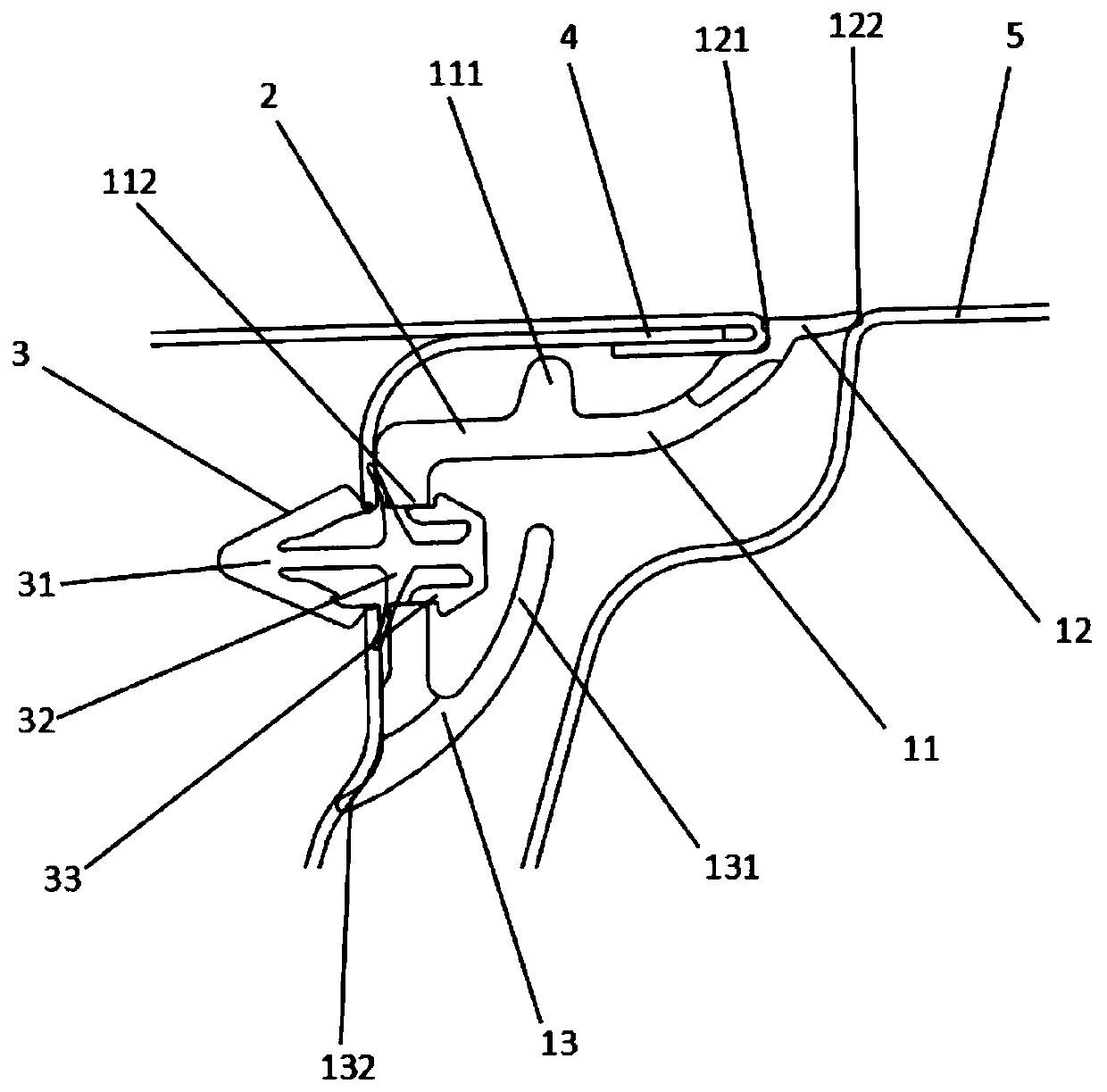

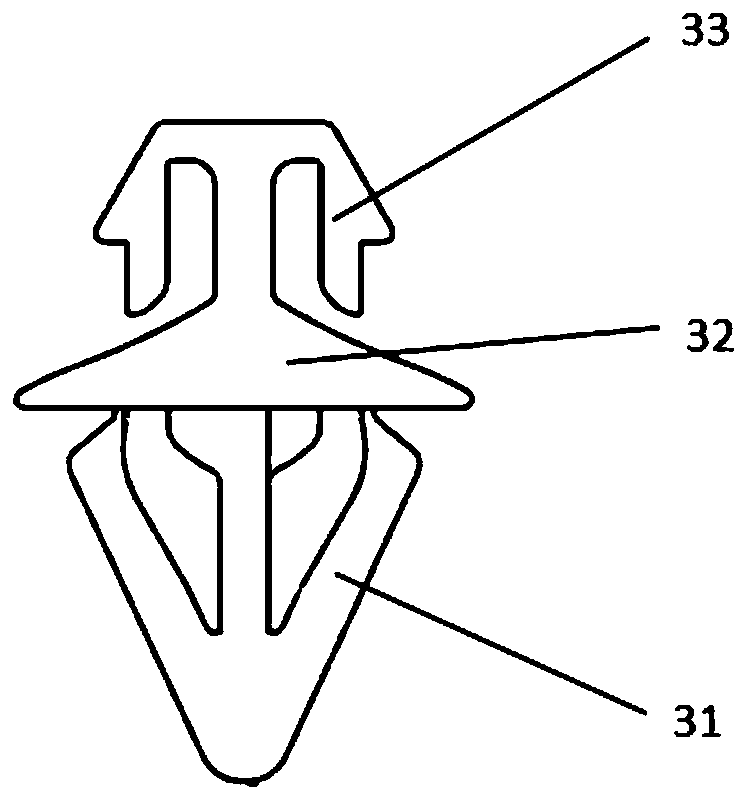

[0022] Ten, such as Figure 2 to Figure 5 , the present invention provides a technical solution: the novel automobile C-pillar door frame sealing structure includes a sealing strip body 2 and buckles 3 . The sealing strip body 2 is composed of a skeleton 11 , an upper soft edge 12 and a lower soft edge 13 ; the buckle 3 is composed of a lower body 31 , an end cover 32 and an upper body 33 .

[0023] The utility model can also be further set as follows: the cross section of the skeleton 11 is an inverted L-shaped structure, the upper end is fixedly connected to the upper soft side 12, the lower end is fixedly connected to the lower soft side 13, and there is a raised rib 111 in the middle position , and there is a certain distance from the rear door to increase the overall strength of the sealing strip skeleton. There are through holes 112 for installing buckles at the position close t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com